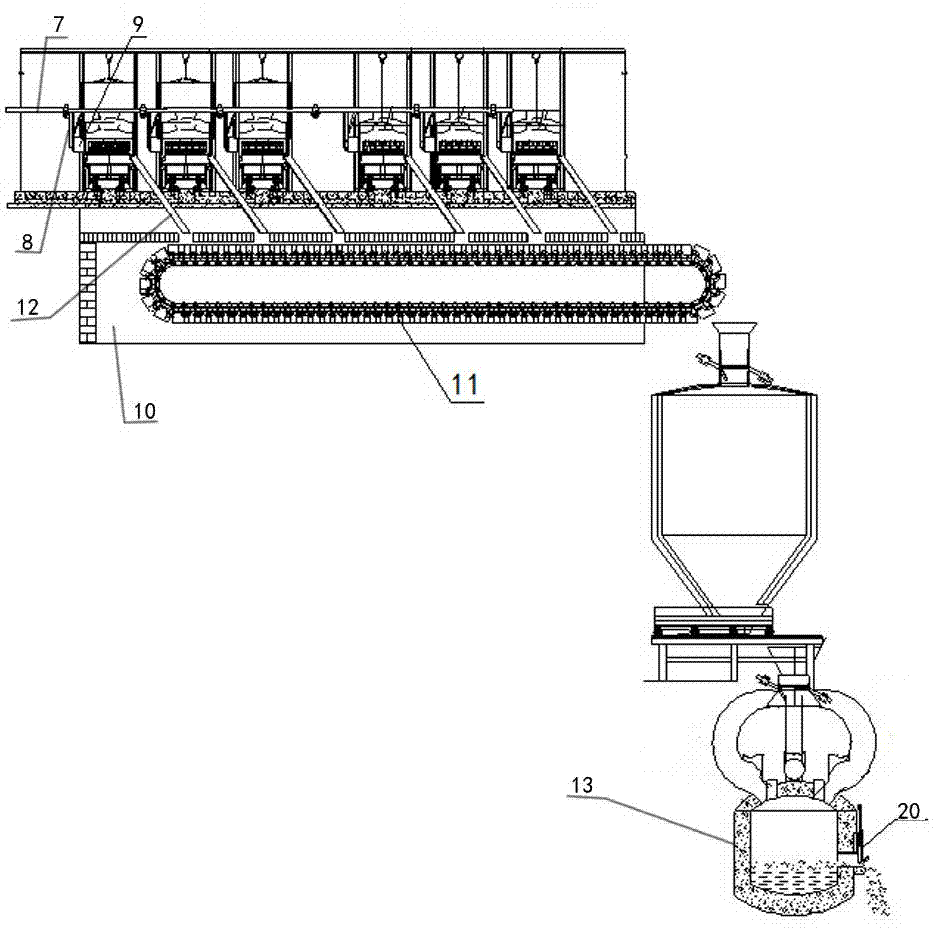

Iron-making method with low grade refractory iron ore and equipment thereof

A low-grade, difficult-to-select technology, applied in the field of ironmaking, can solve the problems of shortage, high energy consumption, long process, etc., and achieve the effect of good effect, low investment and low emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

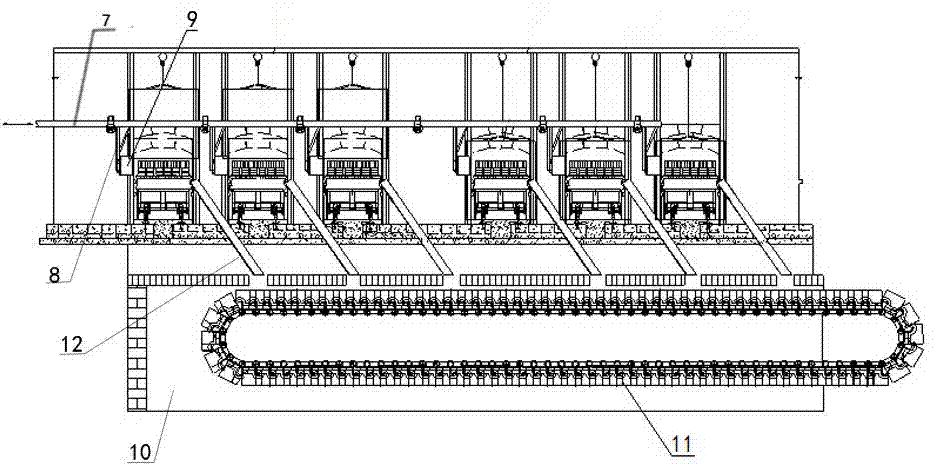

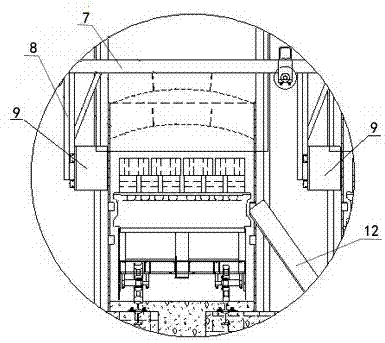

Method used

Image

Examples

Embodiment Construction

[0029] The method of making iron with low-grade refractory iron ore is realized by the following steps: mixing and pulverizing low-grade refractory iron ore and reduced coal, adding flux, catalyst and water to the pulverized ore-coal mixture, stirring through After aging for 72 hours, it is formed into a cuboid block with an external dimension of 240×240×140mm. After the cuboid block is dried, it is sent to a tunnel reduction furnace. , 1200°C) for solid-state initial reduction (the so-called solid-state initial reduction means that the cuboid block does not melt during the reduction process, and is in a liquid state relative to the high temperature of the blast furnace at 1450-1550°C) for 1.8-2.2 hours (optional 1.8 hours, 1.9 hours, 2.0 hours, 2.1 hours, 2.2 hours; the reduction time refers to the cumulative residence time in the high-temperature reduction section, and what is related to the output is the frequency of entering and exiting the reduction furnace. According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com