Electroplating hanger

A hanger and cantilever technology, applied in the electrolysis process, electrolysis components and other directions, can solve problems such as the inability to meet the needs of production, and achieve the effects of improving work efficiency, improving product yield, and setting reasonable quantities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] For further illustrating the present invention, now cooperate with accompanying drawing to elaborate:

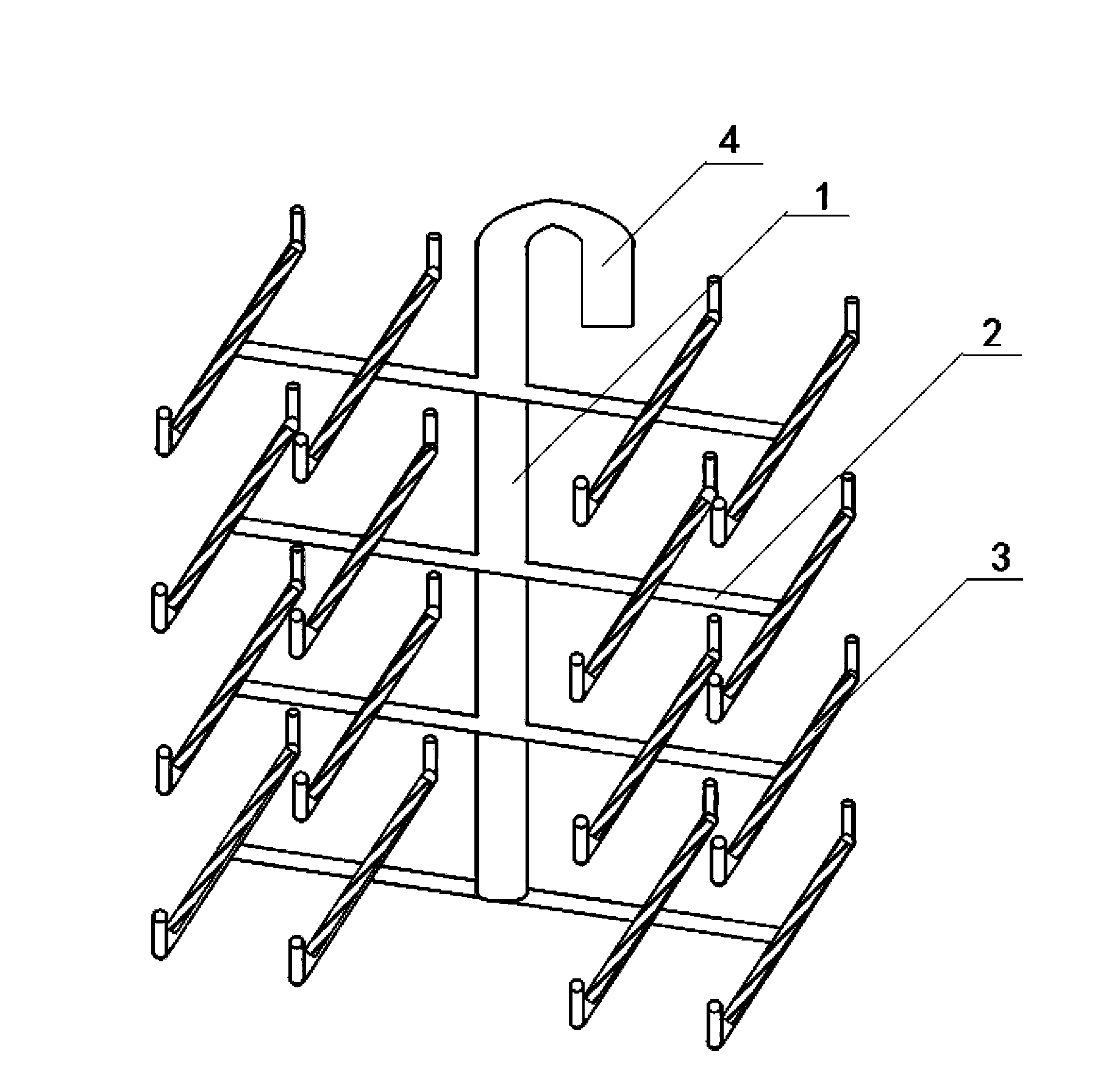

[0023] like figure 1 As shown, the hanger for electroplating includes a main rod 1, a cantilever 2 and a support rod 3 made of metal brass, and the outer surface of the main rod 1, cantilever 2 and support rod 3 is not in contact with the part to be electroplated. Coated with an anti-corrosion insulating paint layer, the upper end of the main rod 1 is provided with a hook 4, and the number of the cantilevers 2 is four, which are respectively welded and fixed vertically with the main rod 1, and the support rod 3 is connected with the cantilever 2 vertically welded and fixed, the number of struts 3 on each cantilever 2 is 4, and the struts 3 are vertically arranged with the main pole 1, the ends of the struts 3 are hooked up, and the struts 3 The outer layer is provided with thread-shaped protrusions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com