Plastering omitting process for shear wall structure

A shear wall, plaster-free technology, applied in building construction, construction, building material processing and other directions, can solve problems such as affecting the beauty and quality of buildings, waste of building materials and man-hours, and inconspicuous effects. The effect of engineering construction area, reducing plastering area and reducing engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

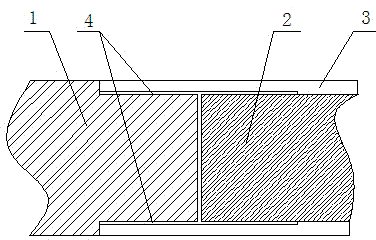

[0038] 1) Shear wall construction: The construction thickness is 140mm, and the thickness of the 10cm part of the wall part of the inner and outer sides of the shear wall connected with the filling wall is reduced by a design plastering thickness of 20mm.

[0039] 2) Masonry construction of filling wall: The thickness of the masonry used is 40mm smaller than that of the shear wall. When building the filling wall, the center of the shear wall is aligned with the center of the filling wall, and a gap of 20mm is left on the inside and outside of the filling wall; The top of the wall is filled with C25 expanded fine stone concrete; then the filling wall is treated at the base level, and the shear wall at the junction with the filling wall is polished with a grinder to remove the laitance and oil stains on the shear wall; The mortar joints of the filling wall shall be fully searched, especially the mortar joints at the junction with the shear wall shall be compacted, and the unquali...

Embodiment 2

[0043] 1) Shear wall construction: The construction thickness is 300mm, and the thickness of the 15cm part of the inner and outer sides of the wall where the inner and outer sides of the shear wall are connected with the filling wall is reduced by a design plastering thickness of 25mm.

[0044] 2) Masonry construction of filling wall: The thickness of the masonry used is 50mm smaller than that of the shear wall. When building the filling wall, the center of the shear wall is aligned with the center of the filling wall, and a gap of 25mm is left on the inside and outside of the filling wall; The top of the wall is filled with C25 expanded fine stone concrete; then the filling wall is treated at the base level, and the shear wall at the junction with the filling wall is polished with a grinder to remove the laitance and oil stains on the shear wall; The mortar joints of the filling wall shall be fully searched, especially the mortar joints at the junction with the shear wall shal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com