Electro-hydraulic servo device

An electro-hydraulic servo and needle-shaped technology, applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problems of small market share of civilian products, inability to form competitiveness, unfavorable development of servo valves, etc., to achieve The effect of high power amplification, small dead zone and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

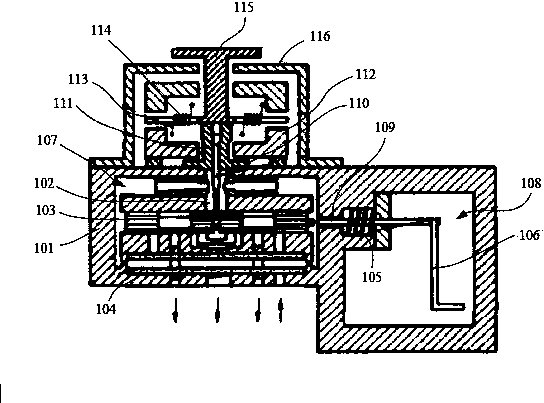

[0024] figure 1 A schematic structural diagram of an electro-hydraulic servo device according to an embodiment of the present invention is shown. Such as figure 1 The shown electro-hydraulic servo device includes a valve body 101, a nozzle 102, a spool valve core 103, a filter screen 104, a buffer spring 105, and a feedback pull rod 106. The valve body 101 is provided with a first cavity 107 and The second cavity 108, the filter screen 104, the spool valve core 103 and the nozzle 102 are all arranged in the first cavity 107, the nozzle 102 is connected with the upper part of the spool valve core 103, the filter The net 104 is located below the slide valve spool 103; a hole 109 is arranged between the first cavity 107 and the second cavity 108, and one end of the feedback pull rod 106 is connected to the hole 109, and the other end of the feedback pull rod 106 is One end is located in the second cavity 108 ; the feedback pull rod 106 is provided with a buffer spring 105 .

...

Embodiment 2

[0030] When the working pressure oil enters the valve from the oil inlet, it enters the oil cavity at both ends of the slide valve through two orifices respectively, and then flows out from the gap between the two nozzles and the needle baffle, and returns to the oil tank. When the control current is input, the needle baffle is in the middle of the two nozzle end faces. At this time, the pressure parameters of the two nozzle holes and the two fixed orifices are equal, so the pressures of the oil chambers at both ends of the slide valve are equal, and the slide valve in an intermediate equilibrium position. Close each channel, the servo valve has no pressure output. The control cylinder of the swash plate of the main hydraulic pump for traveling does not act, so that the main hydraulic pump does not do work. When the input control current I>0, the torque motor will generate a deflection torque, which drives the needle baffle to deflect an angle. At this time, due to the deflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com