A fast energy-saving water heater

An energy-saving water heater, fast technology, applied in water heaters, fluid heaters, heating element materials, etc., can solve the problems of unreasonable structural design and installation of heating pipes, affecting the electric heating efficiency of water heaters, and poor moisture uniformity in the furnace. Achieve the effects of improved thermal insulation performance, simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

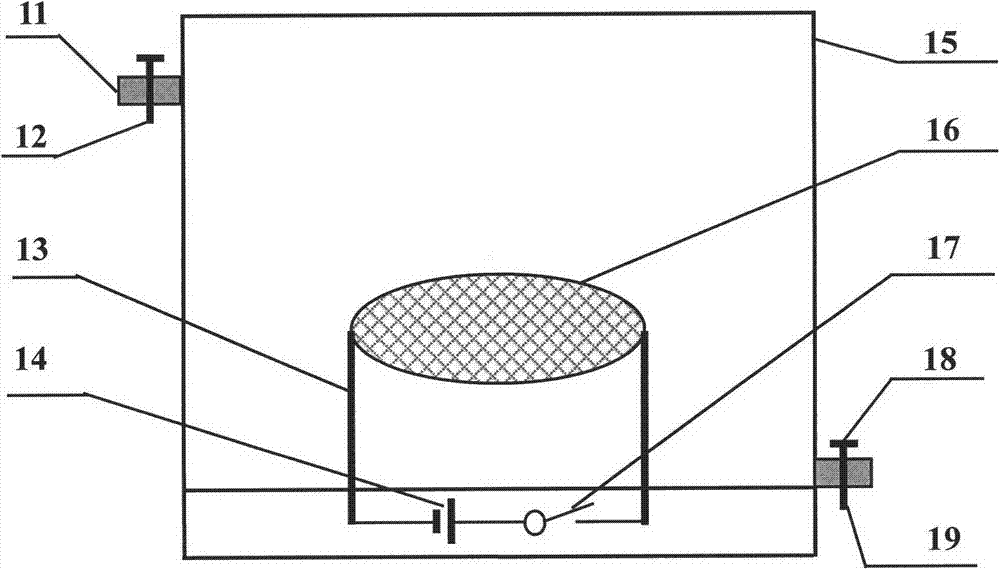

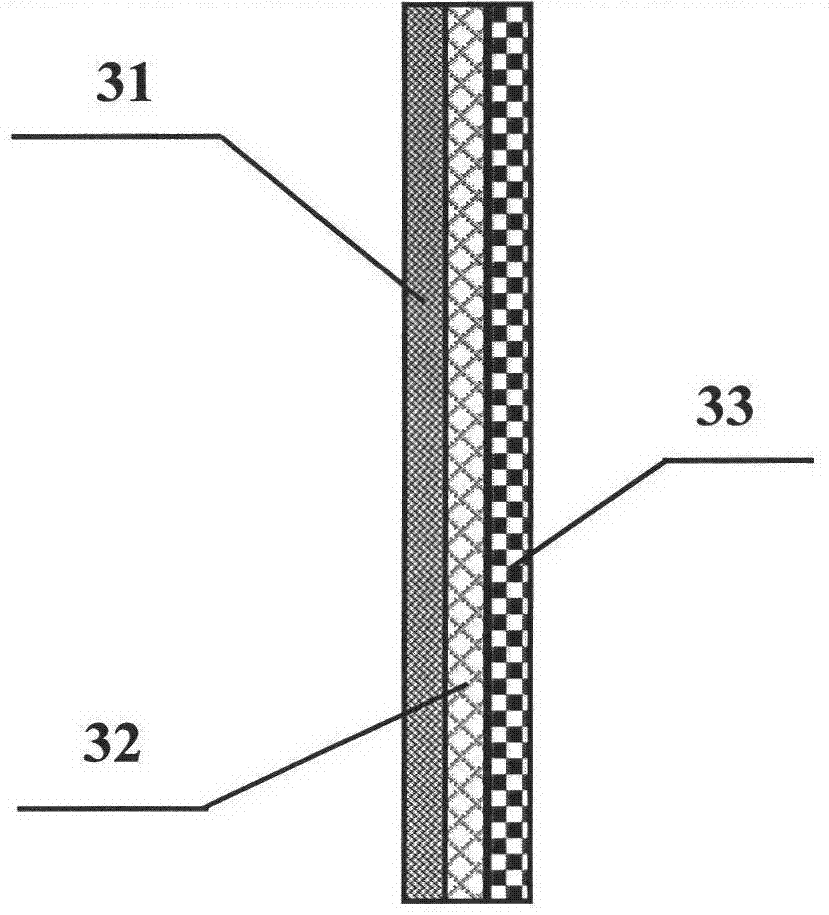

[0021] A fast energy-saving water heater, including a main shell and a heating element. The heating element is made of ceramic matrix material, graphene, and high-temperature-resistant insulating and waterproof layer from inside to outside. The main shell has a sandwich structure, and from outside to inside is a shell structure Protective layer, middle insulation layer, inner high temperature resistant waterproof layer. The ceramic matrix material in the heating element is a ceramic mesh, and the composition is SiC, and the graphene is deposited on the ceramic matrix material by chemical vapor deposition. The ceramic mesh is elliptical and installed at 1 / 6 of the height of the main shell. The middle insulation layer of the main shell can be a vacuum heat insulation board, and the shell structure protective layer of the main shell is an alloy material. The main casing also includes a water inlet, a water inlet regulating valve, a water outlet, a water outlet regulating valve a...

Embodiment 2

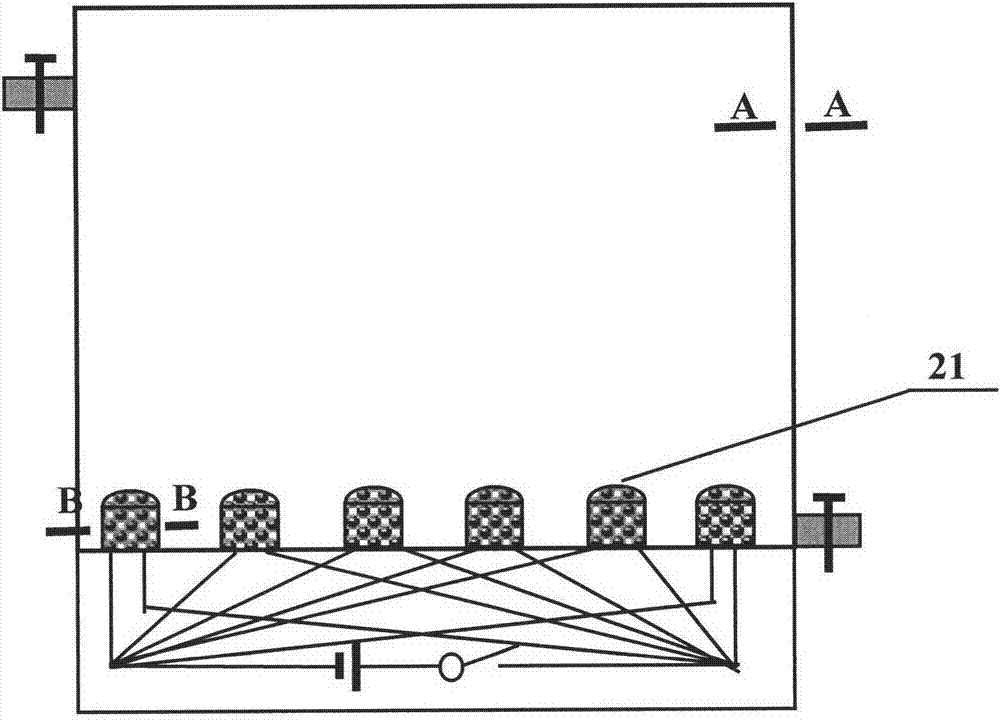

[0023] The fast energy-saving water heater includes a main shell and a heating element. The heating element is composed of a ceramic matrix material, graphene, and a high-temperature-resistant insulating and waterproof layer from the inside to the outside. The main shell has a sandwich structure, and the order from the outside to the inside is: The shell structure protection layer, the middle insulation layer, and the inner high temperature resistant waterproof layer. The ceramic matrix material in the heating element is a ceramic column, the composition is Al2O3, and the graphene is deposited on the ceramic matrix material by chemical vapor deposition. The ceramic columns are evenly installed on the bottom of the main shell, and the ceramic columns are connected in parallel. The middle insulating layer of the main shell is foamed plastics. The shell structure protective layer of the main shell is made of alloy material. The main casing also includes a water inlet, a water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com