Middle through hole dynamic throttling element flowmeter

A throttling element and flowmeter technology, which is applied in the direction of detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., can solve difficulties, bellows are difficult to implement, and affect the promotion of dynamic throttling element flowmeters, etc. problem, to achieve the effect of low price, high adaptability and reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

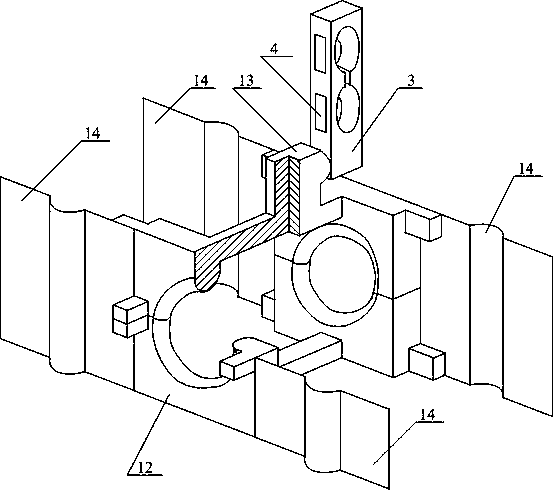

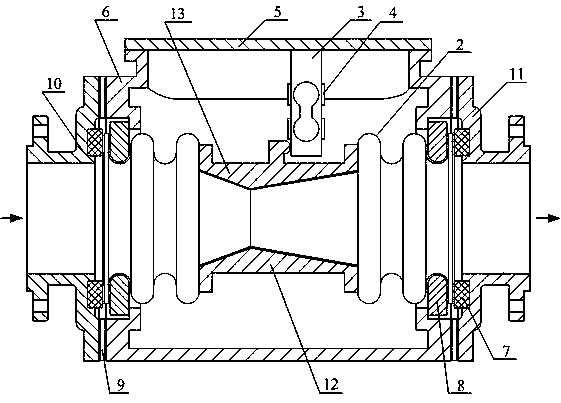

[0014] exist figure 1 In the embodiment, the moving Venturi tube 1 is placed in the middle of the inner cavity of a corrugated tube 2, the outer diameter of the two ends of the moving Venturi tube 1 is slightly smaller than the outer diameter of the middle part, and the two ends of the upper fixed tile 13 and the lower fixed tile 12 are convex. The inner surface of the edge has a shape that matches the trough of the outer surface of the corrugated pipe 2. Because the corrugated pipe is thin-walled, it is easy to produce slight deformation. Therefore, when the upper fixed tile 13 and the lower fixed tile 12 are locked together, the corrugated The inner flange of the fixed tile on the outside of the tube 2 can clamp the outer edges of both ends of the moving Venturi tube 1 with a slightly smaller diameter, so that the mutual positions of the waves between the moving Venturi tube 1 and the bellows 2 remain unchanged during the measurement process. From figure 2 It can be seen i...

Embodiment 2

[0046] exist image 3 In the implementation scheme, it can be seen that this example and figure 1 The embodiments are largely the same in structure, just not like figure 1 Instead of using a separately manufactured dynamic venturi tube 1 as in the above, a single bellows 2 in the shape of a special-shaped bellows is used, that is, the middle section of the bellows 2 is directly made into a venturi profile by means of electrodeposition, chemical deposition or welding. shape. Because the profile of the Venturi tube in the middle section of the bellows 2 is thin-walled, the inner surfaces of the upper fixed tile 13 and the lower fixed tile 12 are made into a shape that matches the profile of the Venturi tube to prevent the corrugated tube 2 from The venturi profile deforms under the internal pressure of the fluid being measured. The upper fixed tile 13 and the lower fixed tile 12 are also made of figure 2 The same supporting spring 14 bears weight, and is not drawn separatel...

Embodiment 3

[0048] exist Figure 4 In the implementation scheme, it can be seen that this example and image 3 The embodiments of the present invention are substantially the same in structure, except that the two ends of the bellows 2 are not fixed with the opening collar 8, but are directly fixed with the watch case 6 inlet pipe and the outlet pipe. For fixing needs, the shape of the two ends of the single bellows 2 matches the shape of the inlet pipe and the outlet pipe of the watch case 6 . Because the diameter of the fixed flange at both ends of the bellows 2 is greater than the diameter of the inlet pipe or the outlet pipe of the watch case 6, the watch case 6 is combined by two parts separated up and down for the mutual assembly of each component. When the flowmeter is connected with the outer connection pipe 15 of the case inlet, the outer connection pipe 16 of the case outlet and the sealing gasket 7, a measured fluid flows in from the outer connection pipe 15 of the case inlet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com