Method for measuring mass flow rate of solid particle in circulating fluidized bed lifting pipe

A particle quality and solid-phase particle technology, which is applied in the field of petrochemical gas-solid riser reactors, can solve problems such as the influence of particle circulation, the inconsistency of gas and solid phase velocities, and the impact on system pressure balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

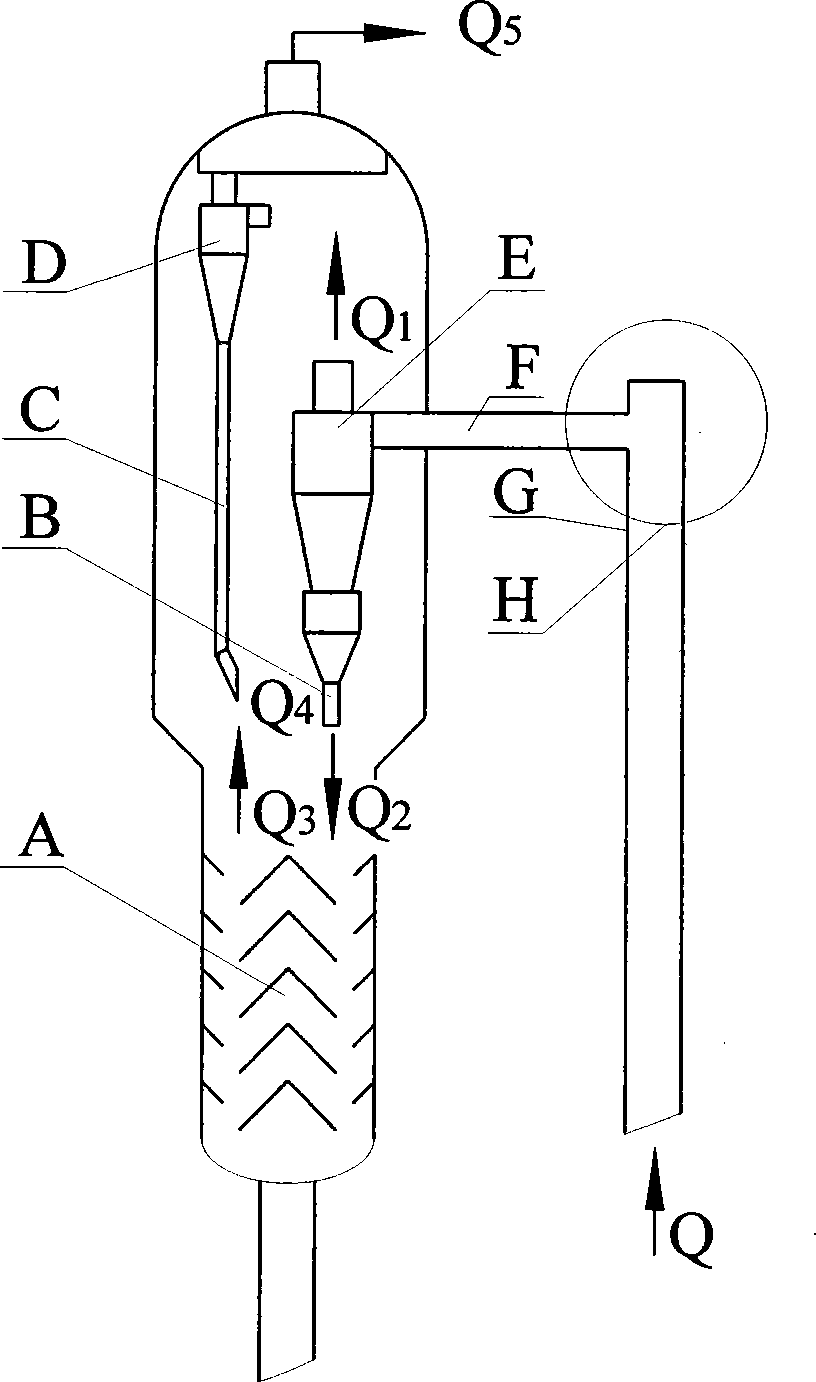

[0062] Below in conjunction with accompanying drawing and specific example the present invention is further described in detail:

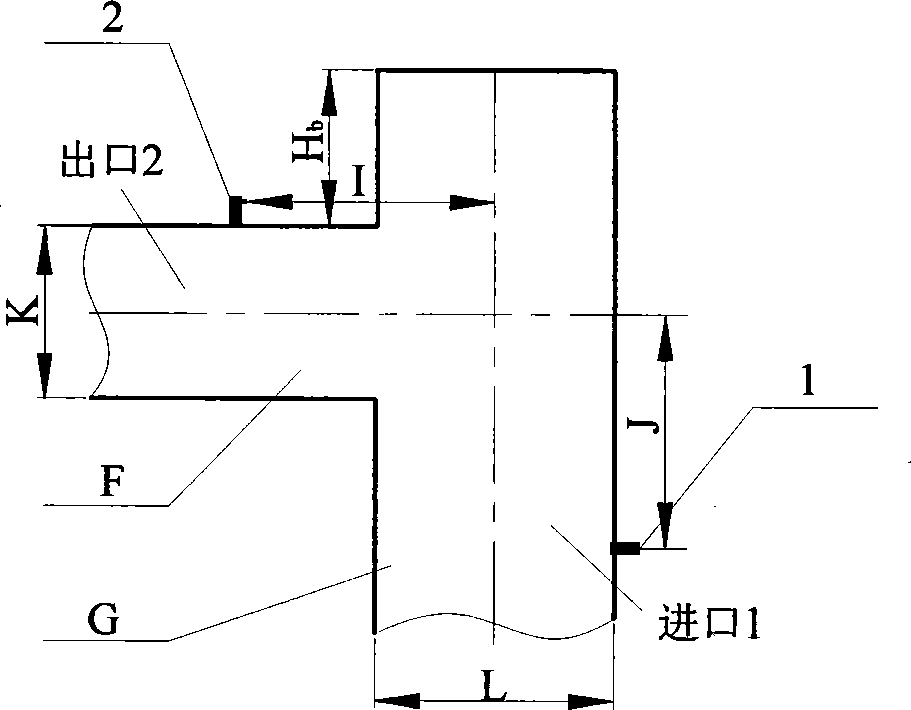

[0063] figure 2 It is a layout diagram of measuring points for a method of measuring the mass flow rate of solid phase particles in a riser of a circulating fluidized bed according to the present invention.

[0064] The measuring device of the present invention adopts a T-shaped elbow structure, does not need to install a scale, has a simple structure, is convenient to operate, and is suitable for measuring the mass flow rate of solid particles under normal pressure or high pressure and high temperature.

[0065] The specific steps of the measurement method in this example are as follows:

[0066] Step 1: Arrange as figure 2 For the measuring points shown, connect a differential pressure sensor or a pressure sensor to measure the pressure difference between measuring point 1 and measuring point 2;

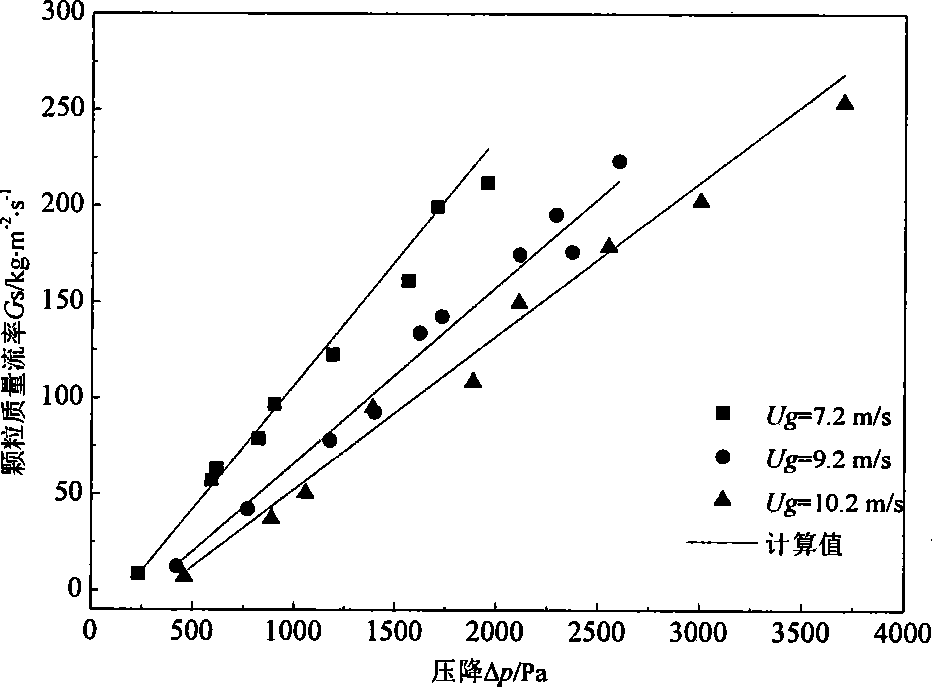

[0067] Step 2: After the circulating fluidiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com