Dynamic sealing performance testing method and device for plunger cylinder sleeve

A test method and dynamic sealing technology, which are applied in the direction of using liquid/vacuum for liquid tightness measurement, and by measuring the acceleration and deceleration rate of fluid, etc. Leakage, reduced production efficiency and other problems, to achieve the effect of high accuracy, accelerated leakage speed, and easy production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

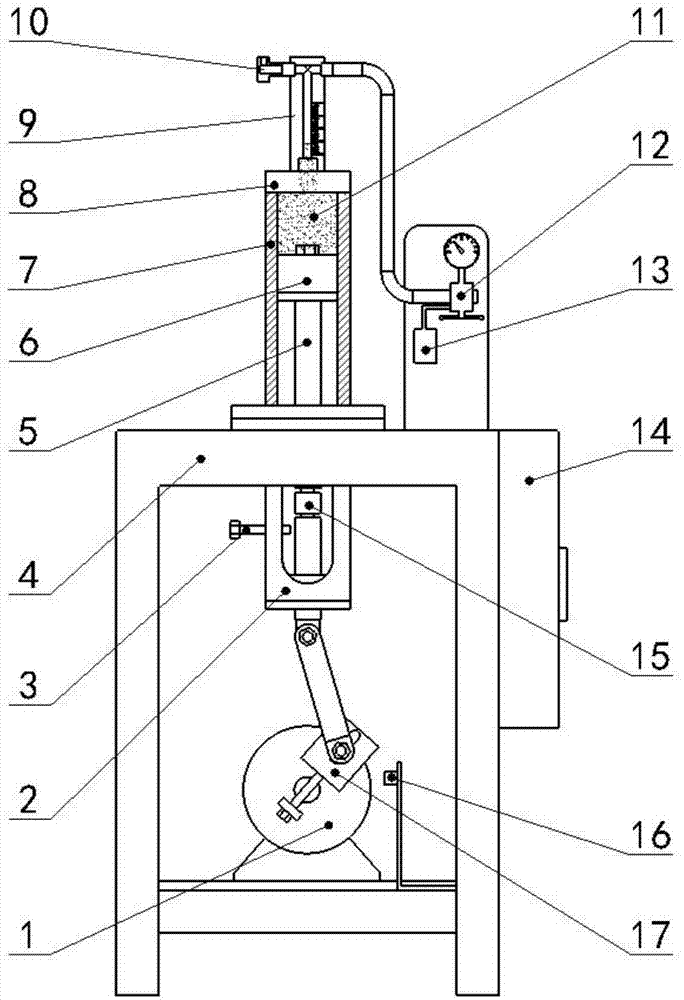

[0025] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, a method for testing the dynamic sealing performance of a plunger cylinder liner is carried out according to the following steps:

[0027] The first step: connect the plunger 6 to the connecting rod 5 of the drive unit and fasten it and place it in the cylinder liner 7, and fix the cylinder liner 7 together with the plunger 6 on the machine base 4;

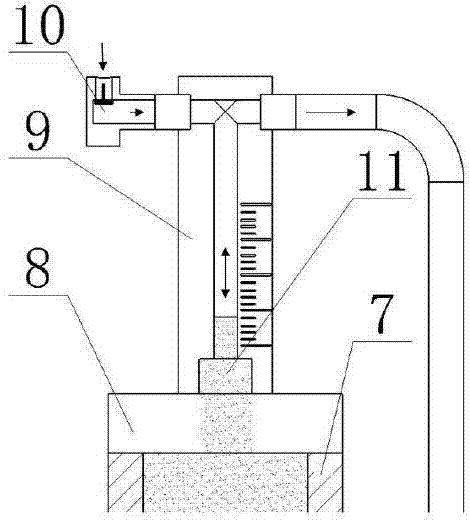

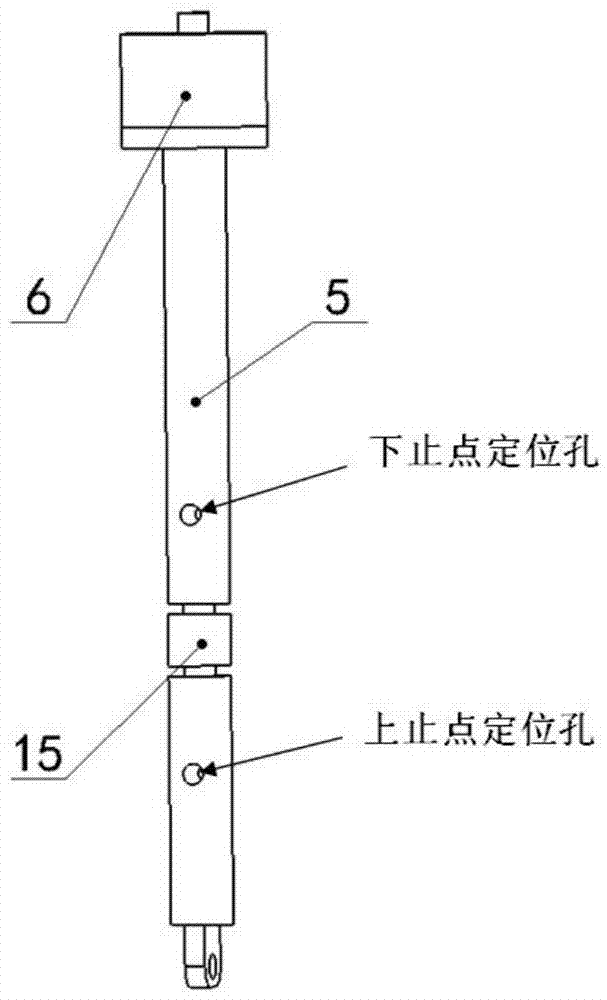

[0028] Step 2: There are two upper and lower positioning holes on the connecting rod 5, turn the crank linkage mechanism to the bottom dead center, insert the positioning pin 3 into the positioning hole at the bottom dead center, inject the leakage liquid 11 into the cylinder liner 7, and ensure that the plunger 6 When moving to the top dead center, the upper liquid level of the leaked liquid 11 is between the lowest scale line and the highest scale l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com