Novel micro-control static friction coefficient tester

A static friction coefficient and tester technology, applied in the field of measuring instruments, can solve problems such as time-consuming, labor-intensive, accuracy, etc., and achieve the effects of ingenious design, improved test efficiency and test accuracy, and simple structure of the test mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

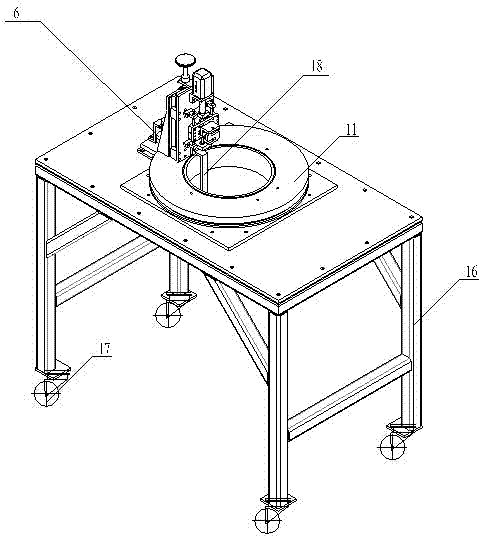

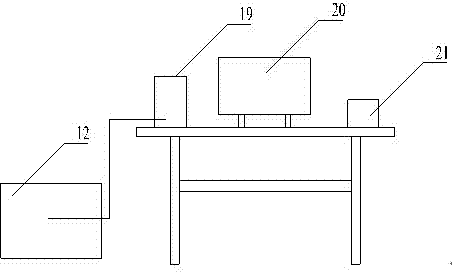

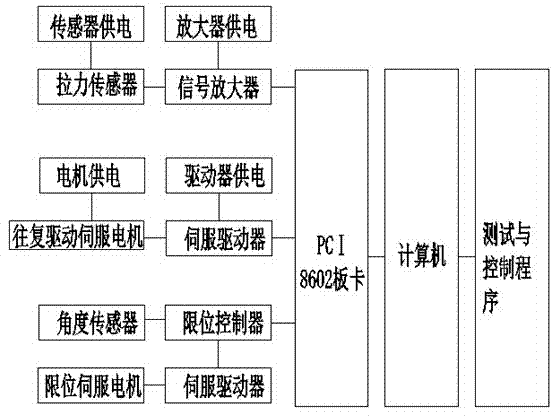

[0034] Such as Figure 1-4 As shown, the new micro-controlled static friction coefficient tester of the present invention includes a testing mechanism, a strong and weak current control mechanism, and a data acquisition and analysis mechanism.

[0035] Wherein, the test mechanism includes a frame body 16, and casters 17 with brakes and adjustable level feet 24 are installed on the bottom of the frame body 16. A horizontal platform 22 with a hollow structure is arranged on the frame body 16 . A circular track is arranged around the hollow structure of the horizontal platform 22, and a circular test platform 11 is arranged on the circular track, and the circular test platform 11 can rotate around the circular track. The limit servo motor 5 is fixedly arranged on the horizontal platform 22, the output shaft of the limit servo motor 5 is fixedly connected to the steering drive wheel 6, and the limit servo motor 5 drives the steering drive wheel 6 to rotate. The sides of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com