Method for detecting solid-phase reaction between inclusions and alloy matrix in thermal treatment process

A technology of heat treatment process and alloy matrix, which is applied in the field of steelmaking technology, can solve the problems of destroying the overall toughness, fatigue resistance and ductility of the alloy matrix, and the influence of the composition and properties of the alloy matrix. , to achieve the effect of obvious compositional change trend, lower ambient oxygen partial pressure, and intensified interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] (1) Using this method to study Fe-Mn-Si steel matrix alloy and MnO-SiO 2 -The solid-state reaction and its mechanism between FeO-MnS oxide inclusions during heat treatment at 1473K. The initial chemical compositions of the alloy and the oxide are:

[0029] Fe-Mn-Si alloy: Fe: Bal., Mn: 3.10%, Si: 0.10%;

[0030] MnO-SiO 2 -FeO oxide inclusions: MnO:66%, SiO 2 : 31%, FeO: 3%.

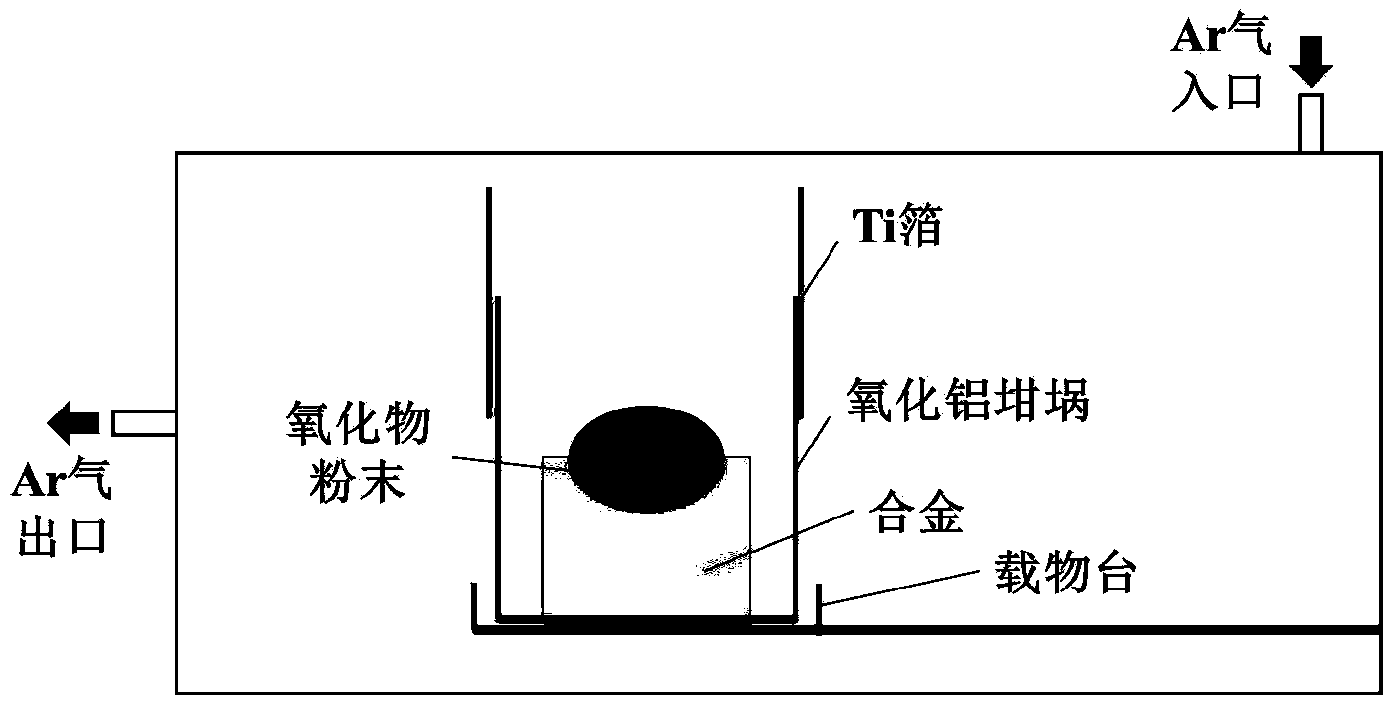

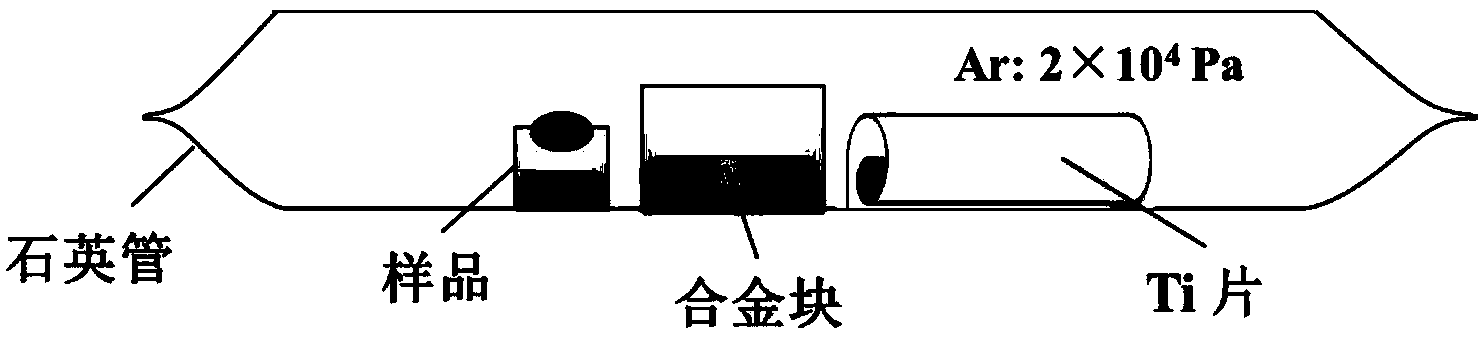

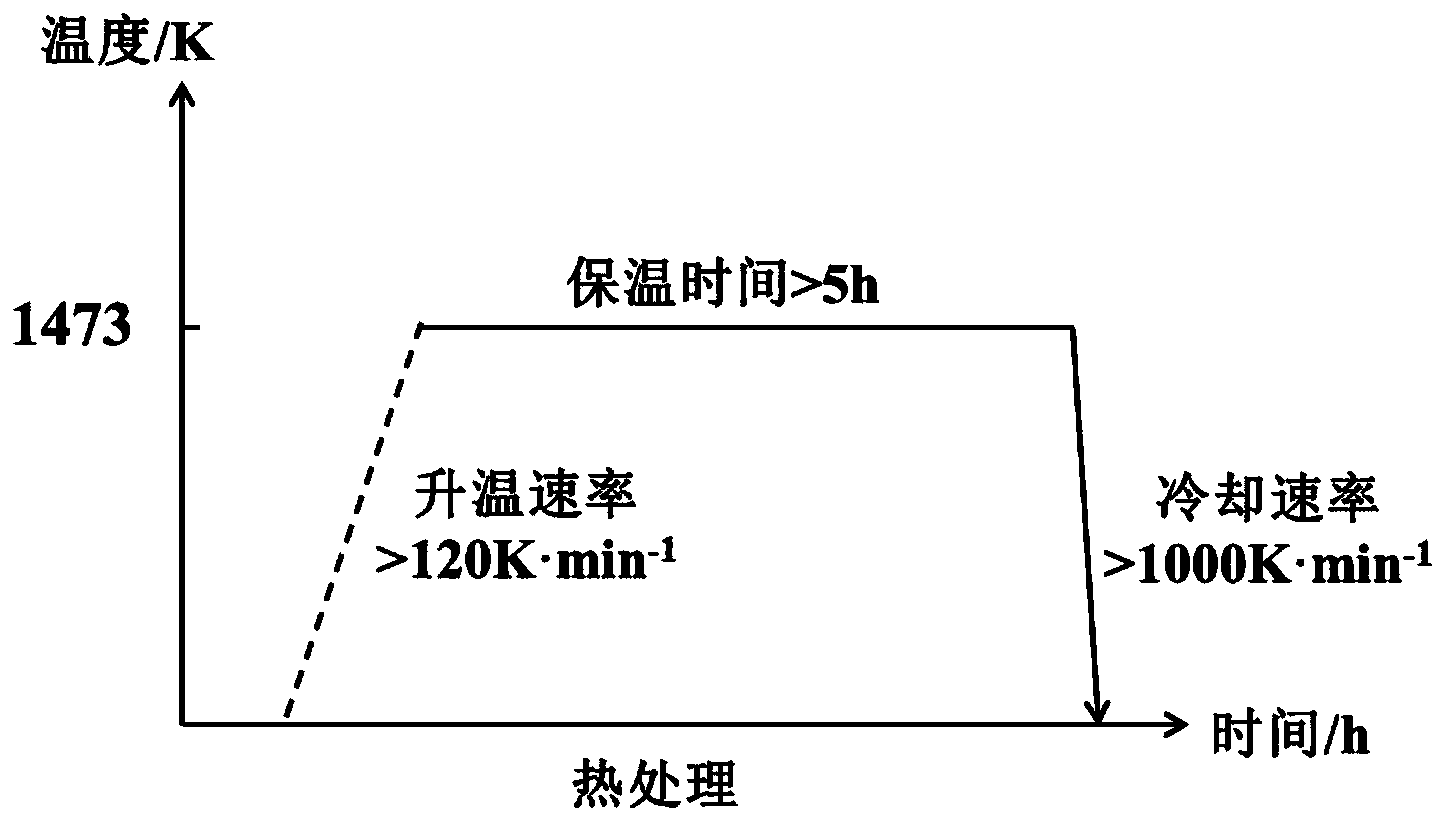

[0031] (2) if figure 1 As shown, the alloy and oxide samples were placed in an alumina crucible used in a high-temperature confocal laser microscope, and the temperature was raised to 1673K (about 50K higher than the melting point of the oxide) at a rate of 100K / min, and then the temperature was rapidly lowered to room temperature, and the cooling rate reached 1000K / min; then, the cross-section of the sample is ground and polished, and subjected to EPMA observation and detection analysis, such as Figure 4 As shown, the oxide inclusions precipitated gray 2MnO-SiO 2 phase and black MnO-SiO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com