A Quantitative Method for Defect Location and Quantification in Billet Ultrasonic Detection

An ultrasonic detection and defect technology, applied in the field of inspection and detection, can solve problems such as low signal-to-noise ratio, inapplicability, extreme unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

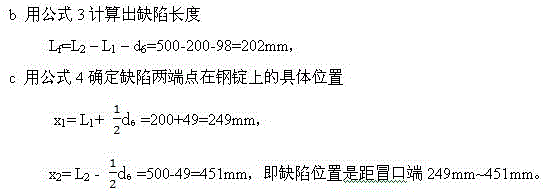

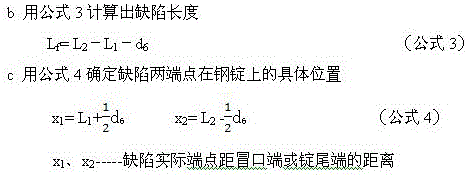

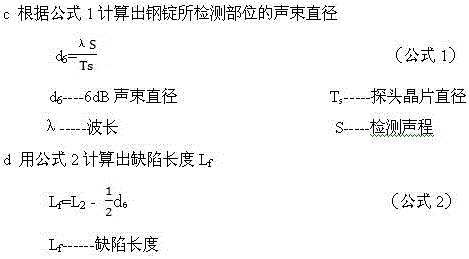

[0025] The invention classifies the abnormal waveform states of large and medium-sized cylindrical extrusion billets or electroslag steel ingots in the process of ultrasonic longitudinal wave detection by contact method, fully considers the similarity of sound beam diameter and sound transmission performance of materials, and performs positioning and quantification respectively. The specific implementation examples are as follows:

[0026] Use a probe with a model of 1MΦ30 to detect billets with a diameter of 1m. Adjust the primary bottom wave height of large and medium-sized cylindrical extrusion billets or electroslag steel ingots (as close as possible to the riser end) to 80% of the scale of the fluorescent screen, and increase the sensitivity appropriately. The test is carried out under the premise that the force is at least 2~4dB.

[0027] 1. Depth positioning of defects

[0028] When using an analog flaw detector, adjust the scanning speed according to 1:2, and set the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com