Detection device for metal embedded pieces of plastic intake manifold

A technology for intake manifolds and detection devices, applied in geophysical measurements, instruments, etc., can solve problems such as surface roughness, laboriousness, and affecting the quality of intake manifolds, and achieve fast detection speed, high accuracy of detection results, and workers The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

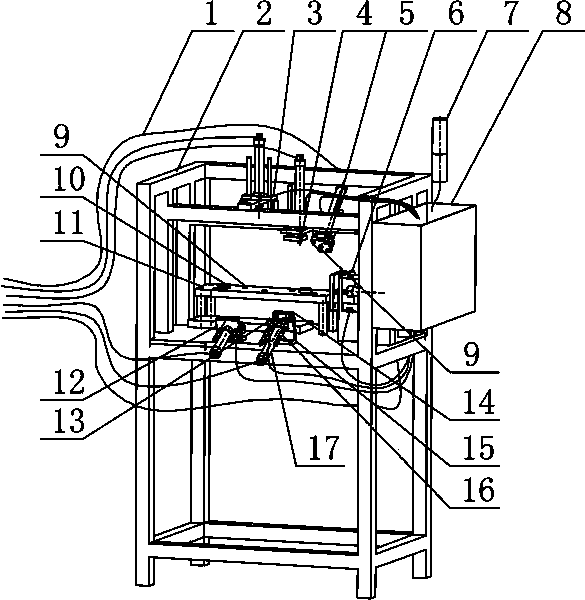

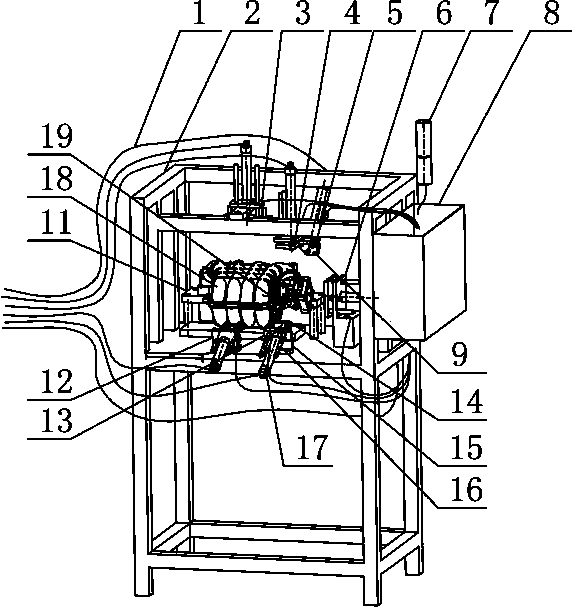

[0011] The device for detecting the metal implant of the plastic intake manifold of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the plastic intake manifold metal implant detection device of the present invention includes a frame 2, a detection probe signal processor 8 and an alarm 7, an operating platform is provided in the middle of the frame, and an air intake is provided on the operating platform. Manifold fixed platen 11, on the intake manifold fixed platen is provided with the positioning projection 10 that matches with the intake manifold exhaust port, on the intake manifold fixed platen is also provided with the detection intake manifold The fixed detection probe 9 of the metal casing connected to the flange surface of the tube engine is also provided with a mobile detection mechanism 6 for detecting the nut connected to the flange surface of the throttle valve on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com