Full-dielectric reflecting film and manufacturing method thereof

A reflective film and all-dielectric technology, applied in gaseous chemical plating, coatings, instruments, etc., can solve problems such as long time-consuming, difficult production, discontinuous production process of reflective film, etc., to achieve continuous process and strong practical significance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

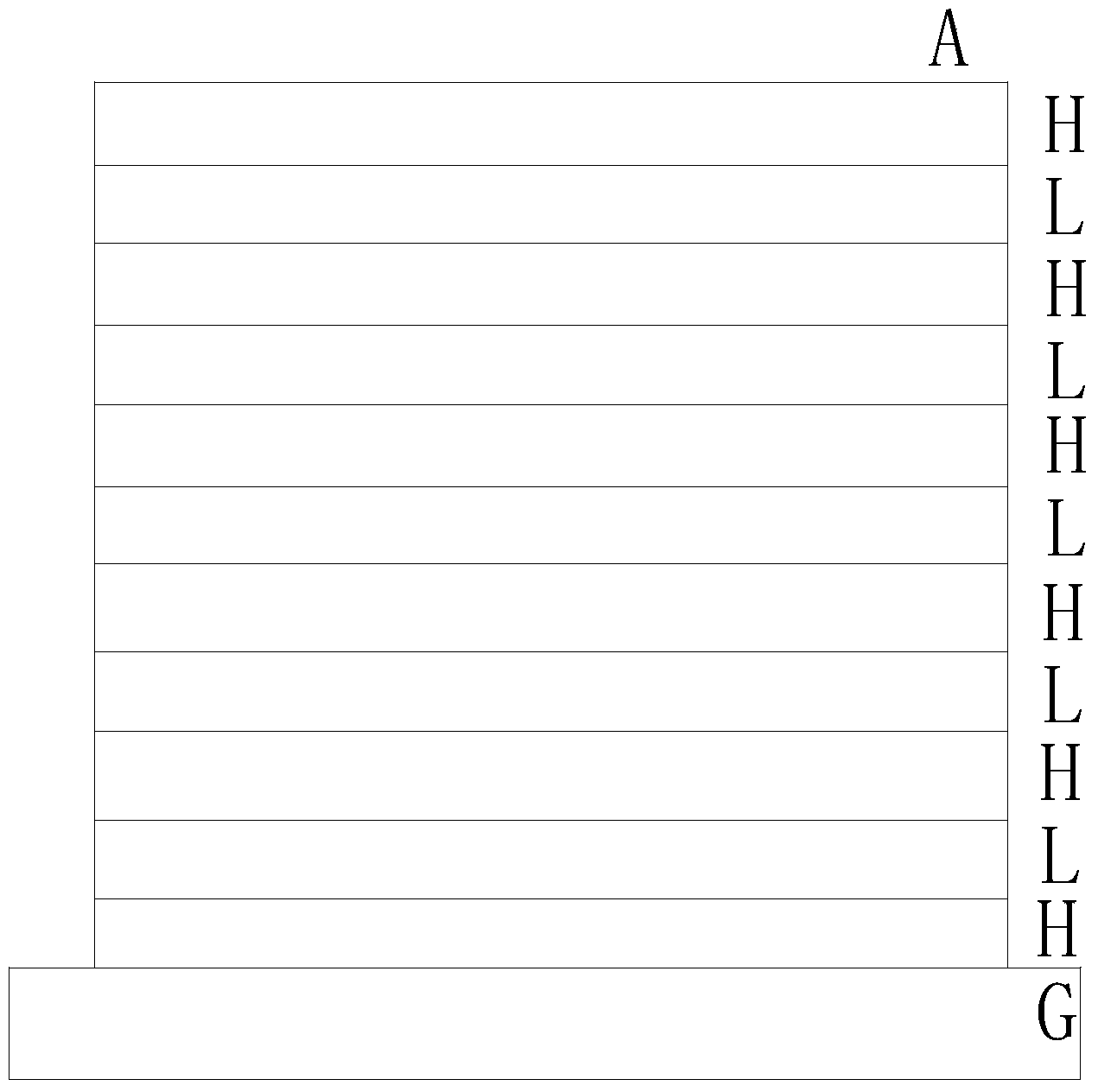

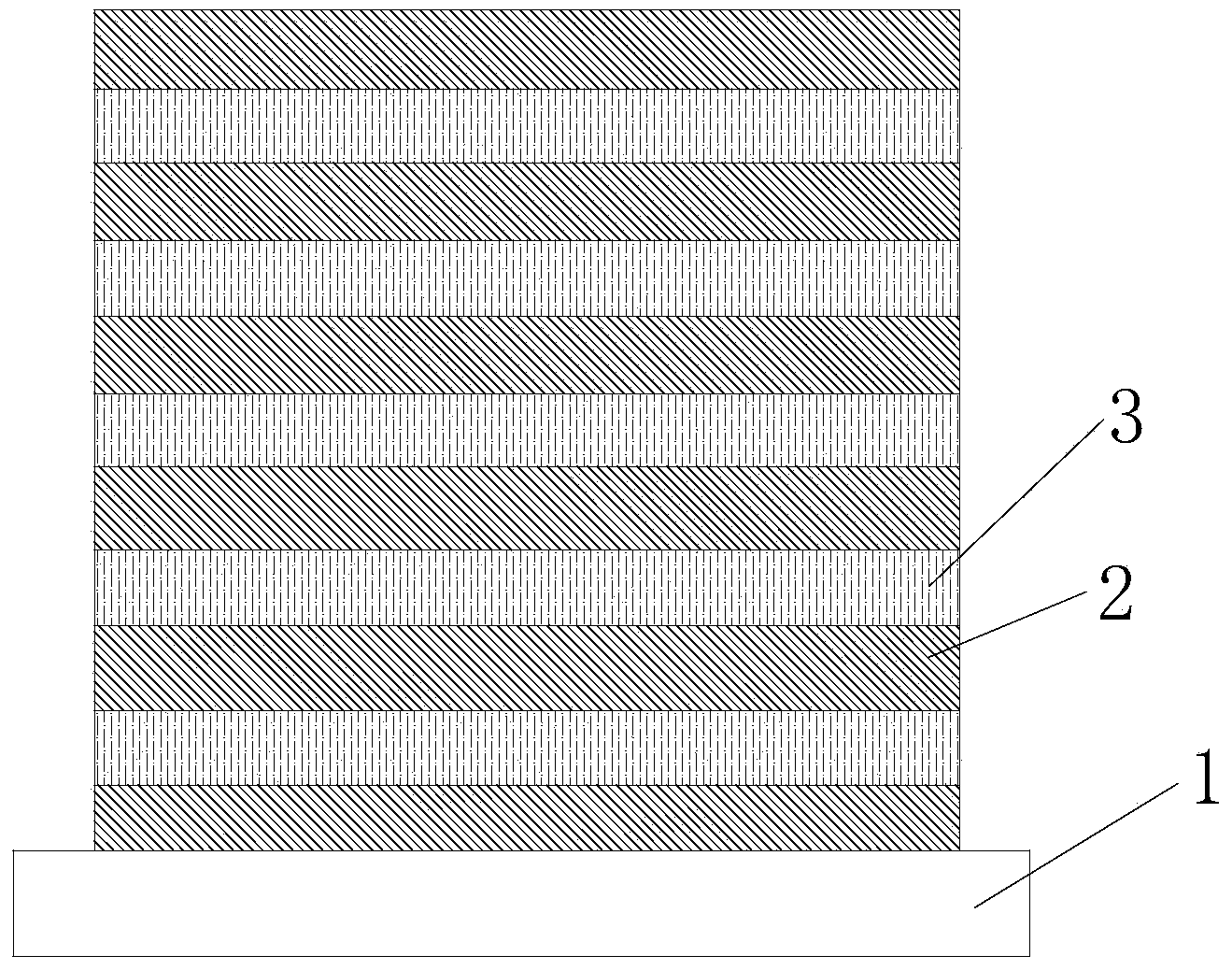

[0026] Such as figure 2 As shown, the total dielectric reflection film includes a substrate 1 and a multilayer high refractive index film layer 2, and the multilayer high refractive index film layer 2 is sequentially stacked on the upper surface of the substrate 1, and the two adjacent layers A low-refractive-index film layer 3 is arranged between the high-refractive-index film layers 2, which is characterized in that: the high-refractive-index film layer 2 has a density of 2.15-2.32g / cm 3 amorphous silicon thin film, the low refractive index film layer 3 has a density of 1.90-2.10g / cm 3 amorphous silicon thin film. The total dielectric reflection film of the present invention adopts a density of 2.15-2.32g / cm 3 The amorphous silicon thin film is made into a high refractive index film layer 2, and the density is 1.90-2.10g / cm 3 The amor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com