Raster scanning type three-dimensional printing machine

A technology of raster scanning and printing machines, which is applied in the field of digital printing machines, and can solve the problems of easy wear, easy damage of LCD screen, and low resolution of printers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0060] Implementation case 1, a black and white LCD screen is used to construct an exposure unit of a raster-scanning three-dimensional printing machine.

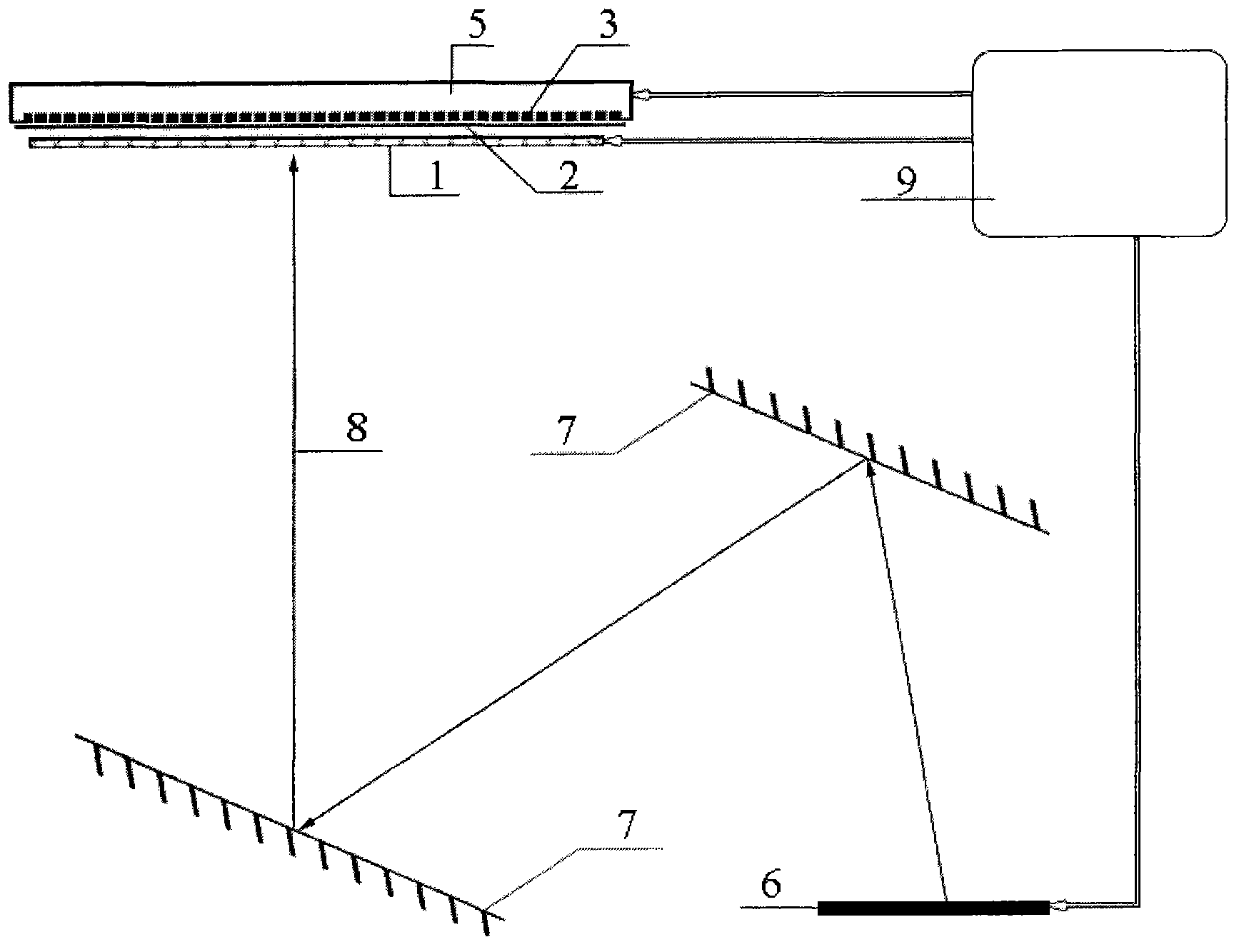

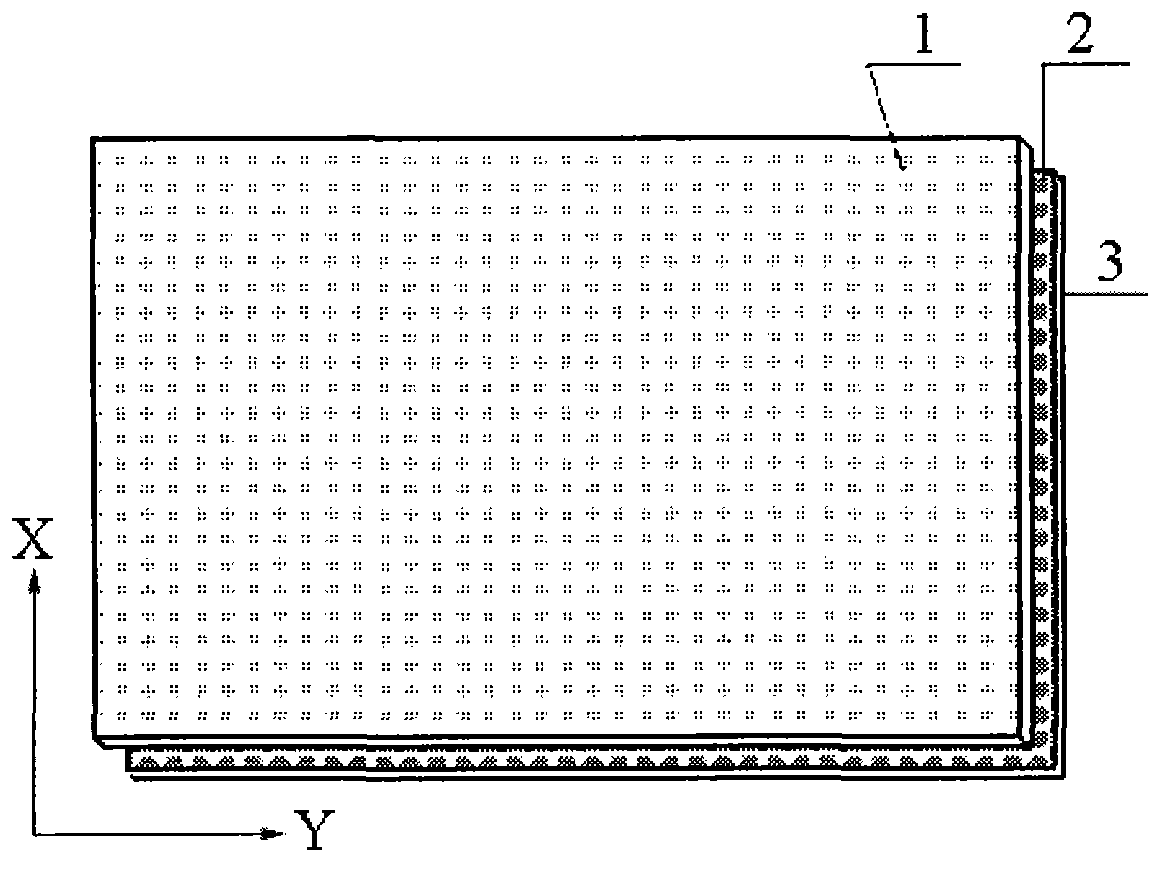

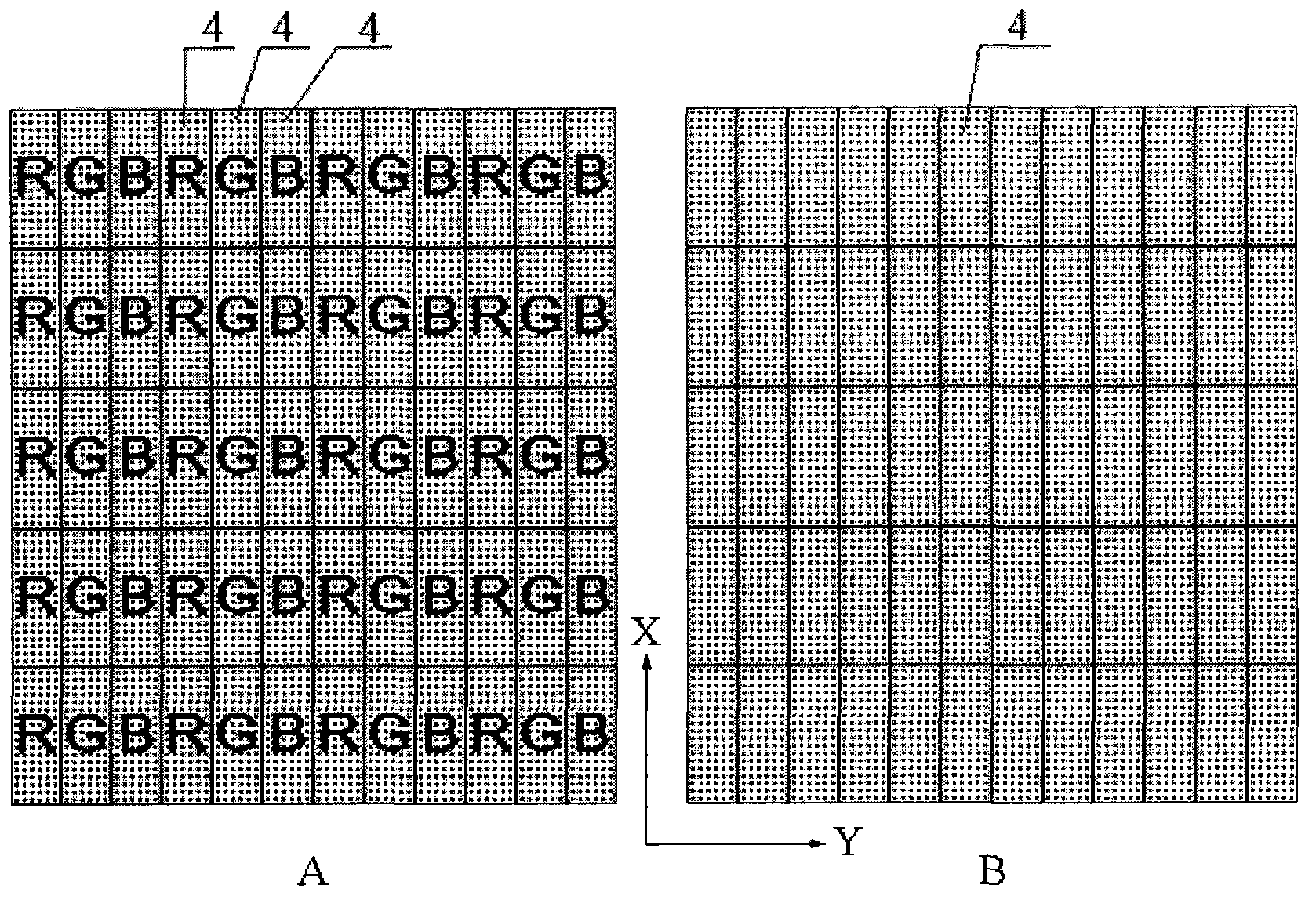

[0061] The exposure unit is composed of a control computer (9), an exposure light source (6) composed of two LED light groups L2 and L5, a black and white LCD screen (1), a scanning grating (2), a photosensitive material fixed platform and a scanning displacement mechanism (5) . The optical distance from the light source to the LCD screen is about 2M, and two reflective mirrors are used in the middle to reflect the light, and the thickness of the glass substrate of the scanning grating is 2mm. The exposure time can be accurate to 1 millisecond. The scanning displacement mechanism (5) drives the fixed platform of the photosensitive material to scan displacement in the X direction, and the precision can reach 1 micron. The native resolution of the LCD screen is 1920*1200, and the clarity of black and white images can be displ...

Embodiment example 2

[0066] In the second implementation case, the exposure unit of a raster-scanning three-dimensional printer is constructed with a color LCD screen.

[0067] The exposure unit consists of a control computer (9), an exposure light source (6) composed of six LED lamp groups L1, L2, L3, L4, L5, and L6, a color LCD screen (1), a scanning grating (2), and a fixed platform for photosensitive materials And scanning displacement mechanism (5) constitutes. The optical distance from the light source to the LCD screen is about 2M, and two reflective mirrors are used in the middle to reflect the light, and the thickness of the glass substrate of the scanning grating is 2mm. The exposure time can be accurate to 1 millisecond. The scanning displacement mechanism (5) drives the photosensitive material fixed platform to scan and displace in the X direction, with an accuracy of 1 micron. The native resolution of the LCD screen is 1920*1200. Interpolate each parallax sequence image into 1920*120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com