Seedling plug tray sowing equipment

A complete set of equipment and hole tray technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of automation, unstable performance, poor combination of agricultural machinery and agronomy, and differences in agronomic requirements. Achieve the effects of eliminating potential safety hazards, reducing seeding costs, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

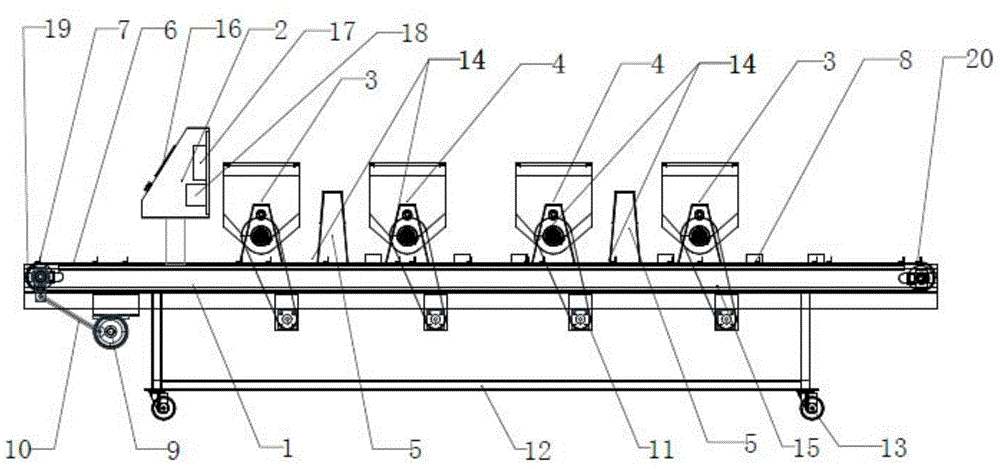

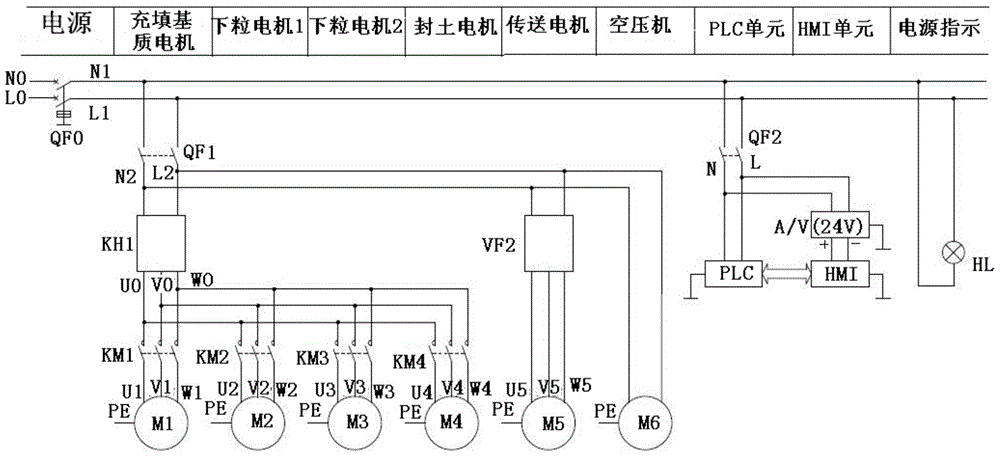

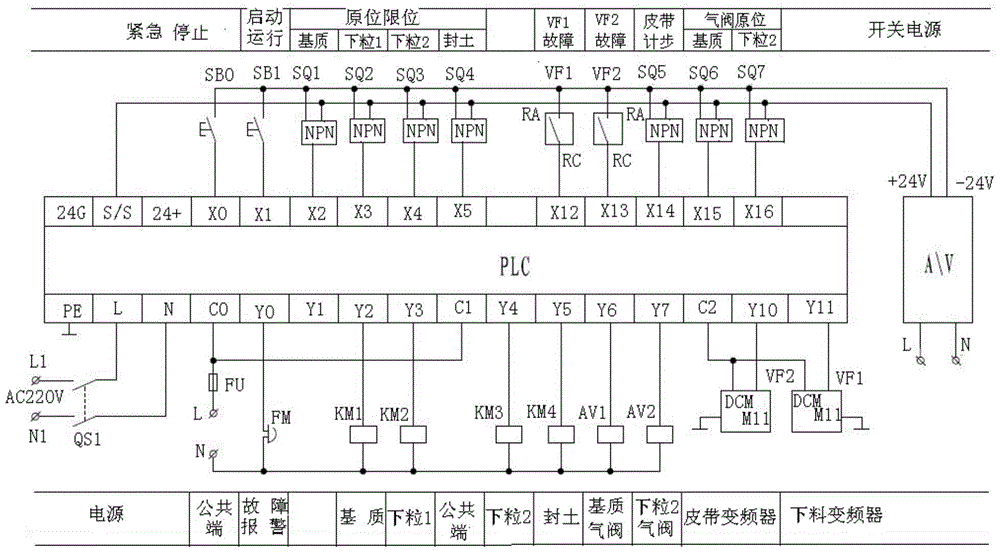

[0019] Such as Figure 1-3 As shown, the complete set of equipment for sowing seedling trays includes a frame 1, a conveying device, a filling matrix device 3, a seeding device 4, a pressure hole device 5, a pneumatic device 14, and a control device. The conveying device includes a motor 9 and a transmission guide rod. 10. The active roller shaft 19, the passive roller shaft 20, the tray positioning assembly 7 and the conveyor belt 6, which carry the tray and work intermittently at a constant speed according to the linear speed. A support frame 12, a motor 9 and a transmission guide rod 10 are arranged below the frame 1, a group of ground wheels 13 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com