Patents

Literature

49results about How to "Reduce seeding costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

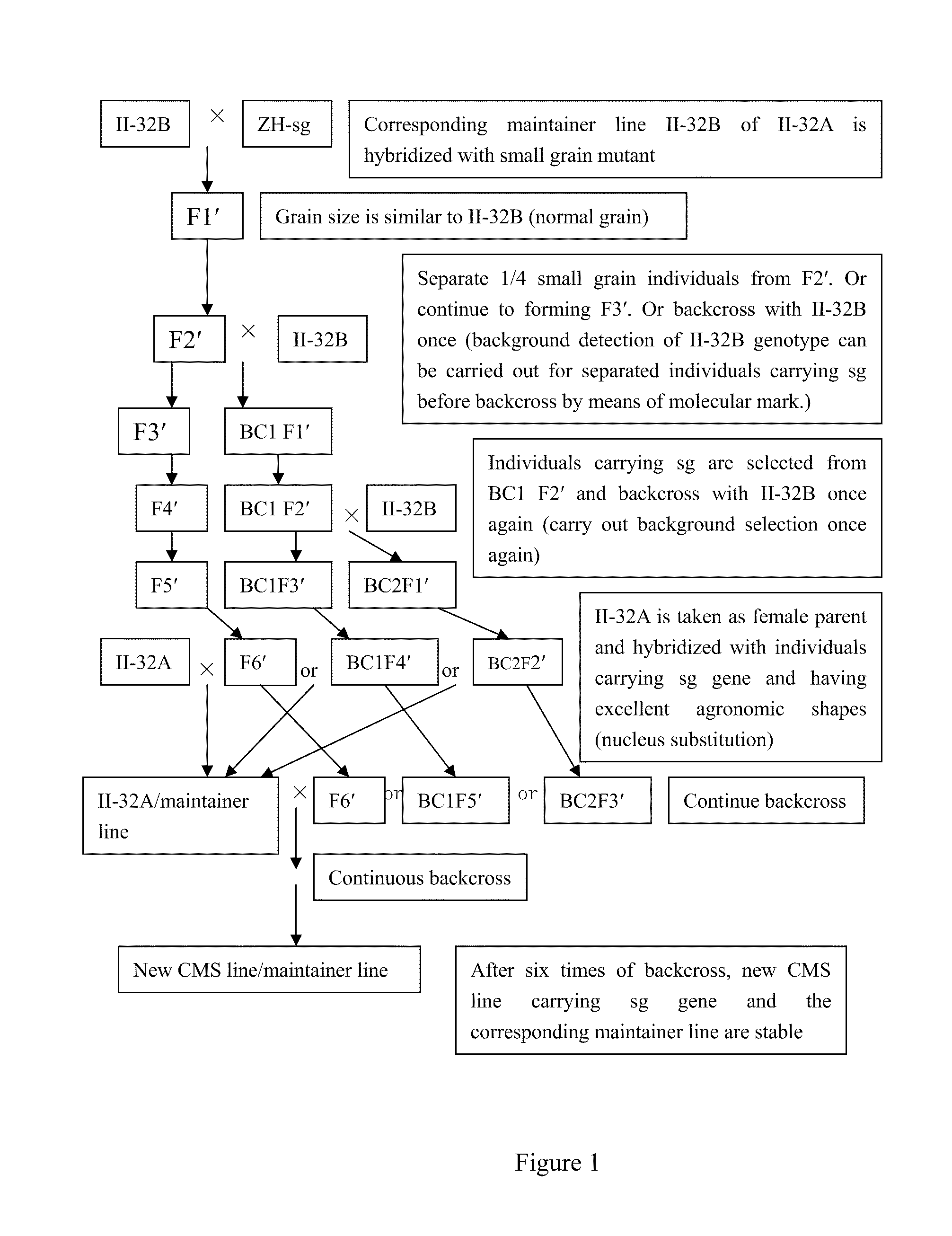

Hybrid rice seed production method

InactiveUS20110232247A1Reduce areaImprove land use efficiencyCrop conditionersMowersBiotechnologyRice farmers

The invention relates to a method for simplifying hybrid rice seed production procedure and improving the working efficiency of seed production. The method comprises the following steps: (1) breeding small grain CMS or GMS line and corresponding hybrid rice having characteristics of rice (Oryza sativa) ZH-sg (Zhonghua 11 small grain mutant) with the accession number of CGMCC No. 2741; (2) hybridizing the small grain CMS line with large grain or normal grain restorer line hybrid rice for seed producing; (3) carrying out mechanized seed production of mixing sowing and mixing harvesting by utilizing small grain CMS line hybrid rice; (4) seed cleaning and separation after mechanical harvest. The invention can save a large amount of seed production field, reduce the investment of labor force in seed production, simplify the operation procedure and reduce mechanical admixture, storage and transportation cost and buying cost of hybrid rice seeds for rice farmers.

Owner:CHINA NAT RICE RES INST

Double-layered growing method for lucern in mountainous areas of arid regions

InactiveCN102308720AIncrease success rateImprove effectivenessHorticultureAridOrthogonal test design

The invention relates to a double-layered growing method for lucern in mountainous areas of arid regions. The method is characterized in that: grandifoliate lucern is adopted as a main grown variety, an annual associated plant variety, such as rape, oat or highland barley, is chosen, and by means of a orthogonal test design and sowing order (position), growing spacing, growing depth, amount of applied fertilizer and other technical measures, and by utilizing the concealing and protectin effect generated by the double-layered growing method for the lucern in mountainous areas on lucern seedlings, the double-layered growing method can increase the current survival rate of the lucern seedlings. The double-layered growing method can promote the success of desert grassland improvement and artificial pasture construction under the environmental conditions of arid mountainous areas, becomes an optimal technology portfolio for growing lucern at medium and high altitudes in mountainous areas of arid regions, and greatly increases the survival rate of lucern in desert grassland restoration and artificial pasture construction and the yield of currently grown lucern in mountainous areas of arid regions at the altitude of 3000 to 1800 meters.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

Potato seed breeding method

The present invention relates to a reproduction method of potato seed. Said method includes the following steps : firstly, utilizing detoxified seedlings to reproduce raw seed potato seeds, then utilizing matrix cultivation to reproduce raw seed potato seeds, then using 85-90% of raw seed potato seeds to make native reproduction and can directly supply first-grade potato seeds for production, and utilizing residual 10%-15% of raw seed potato seeds to make cold allopathic reproduction of first-grade potato seeds, and then utilizing said first-grade potato seeds to make cold allopatric reproduction to directly supply and produce second-grade potato seeds.

Owner:CHINA AGRI UNIV

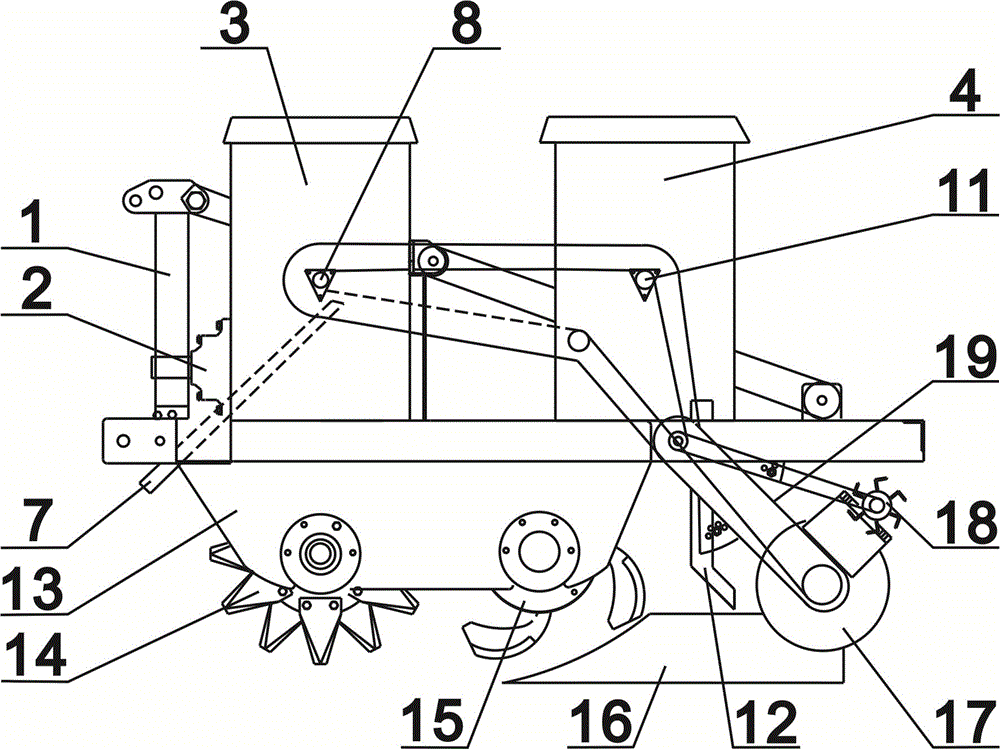

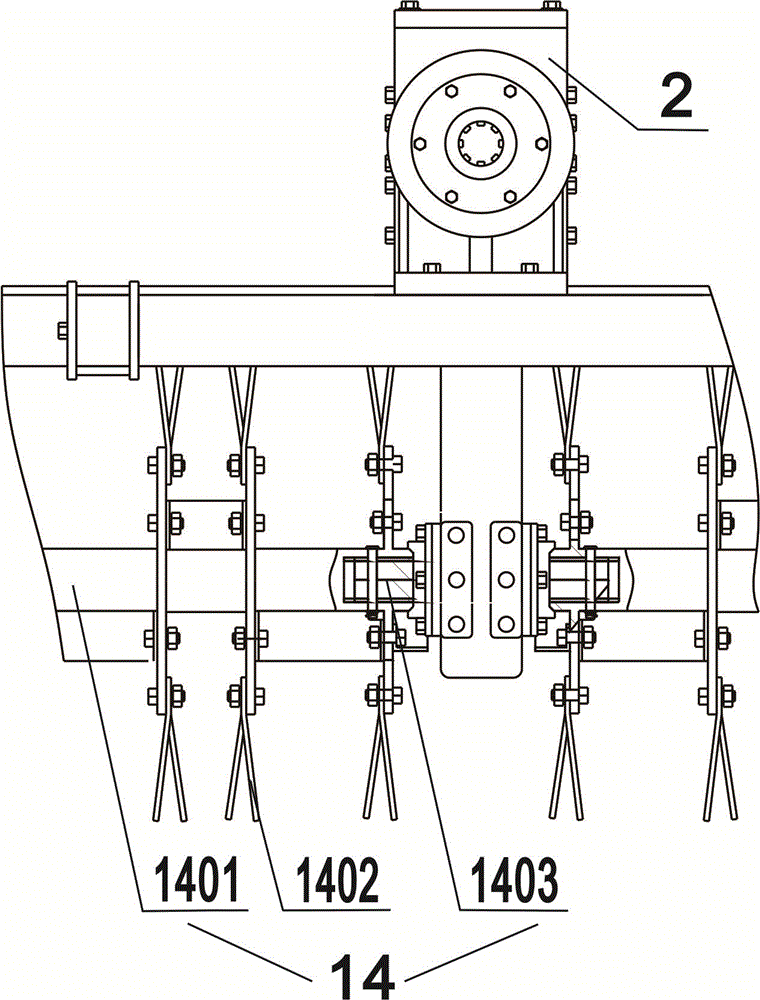

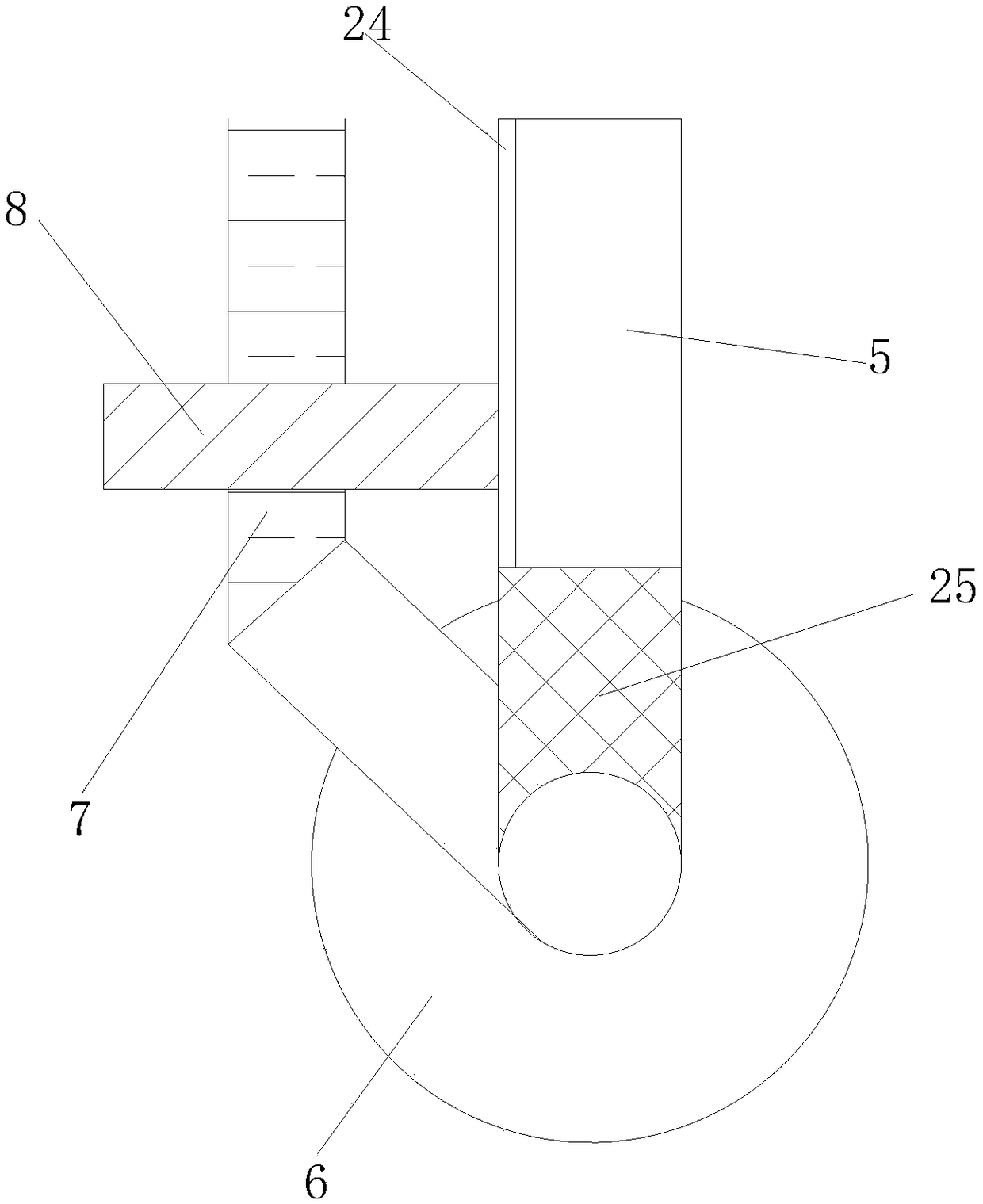

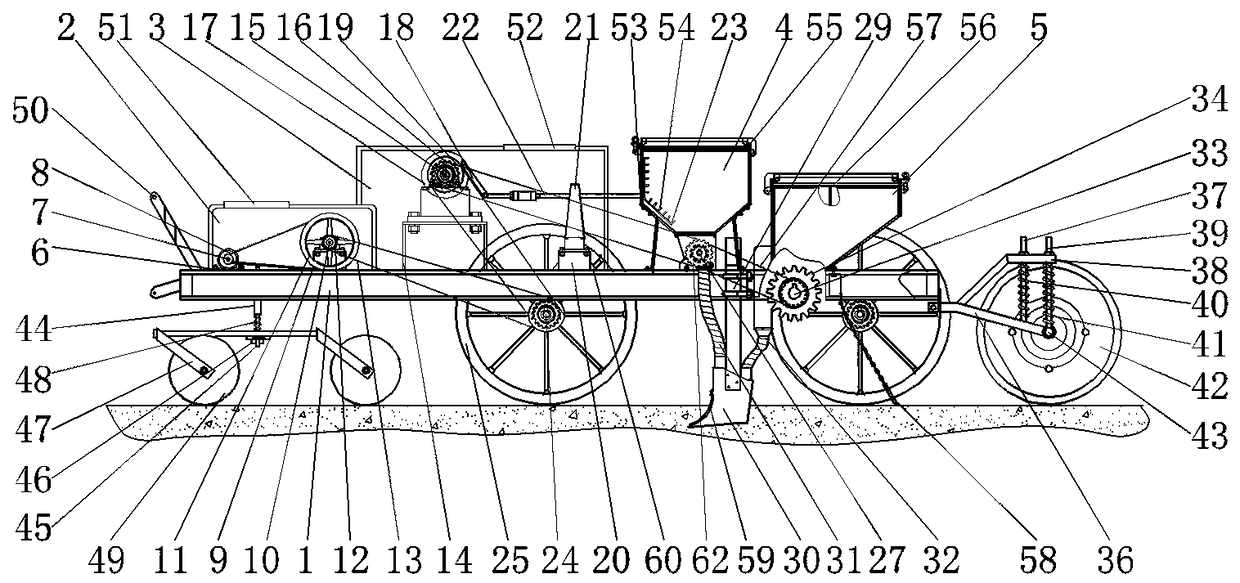

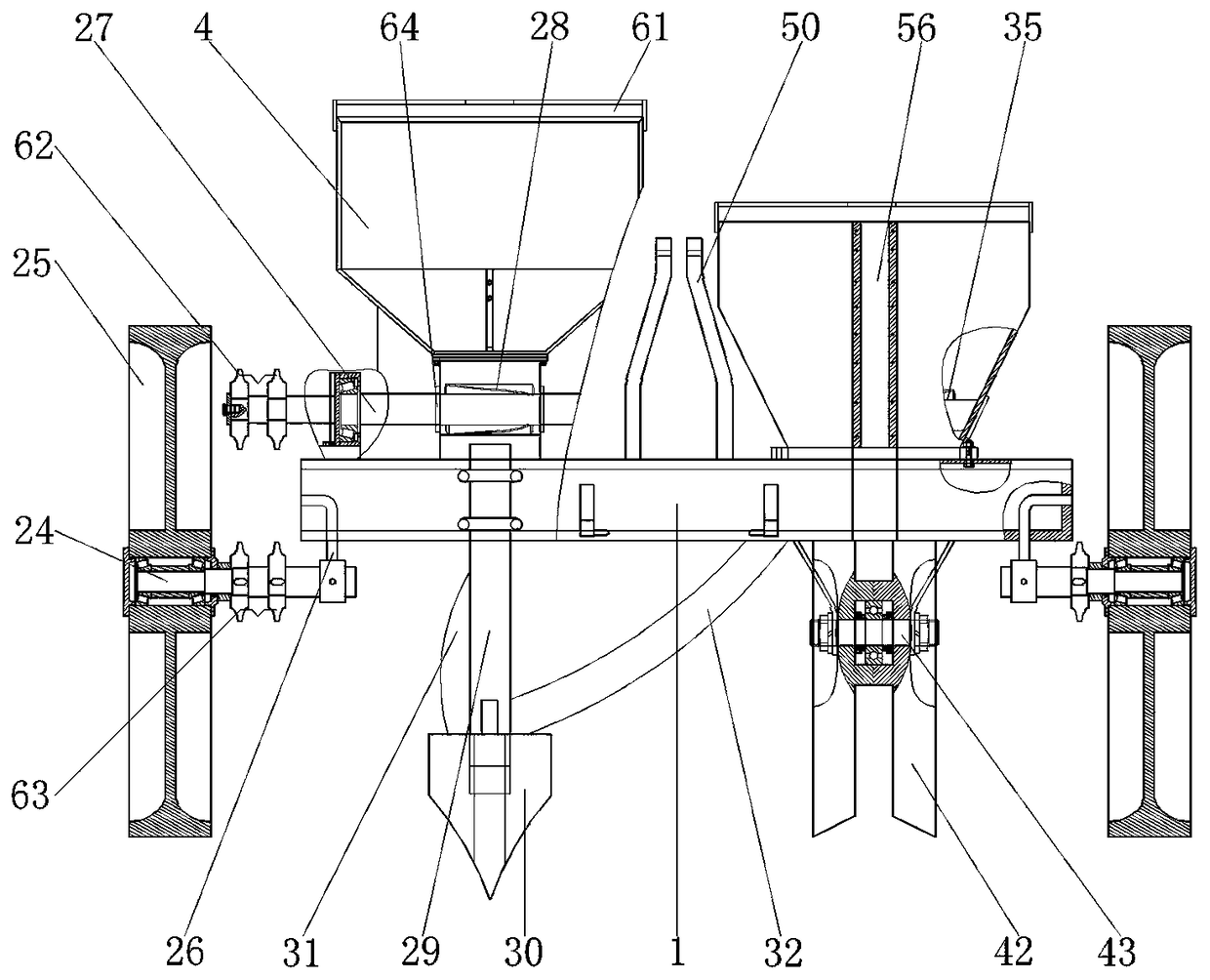

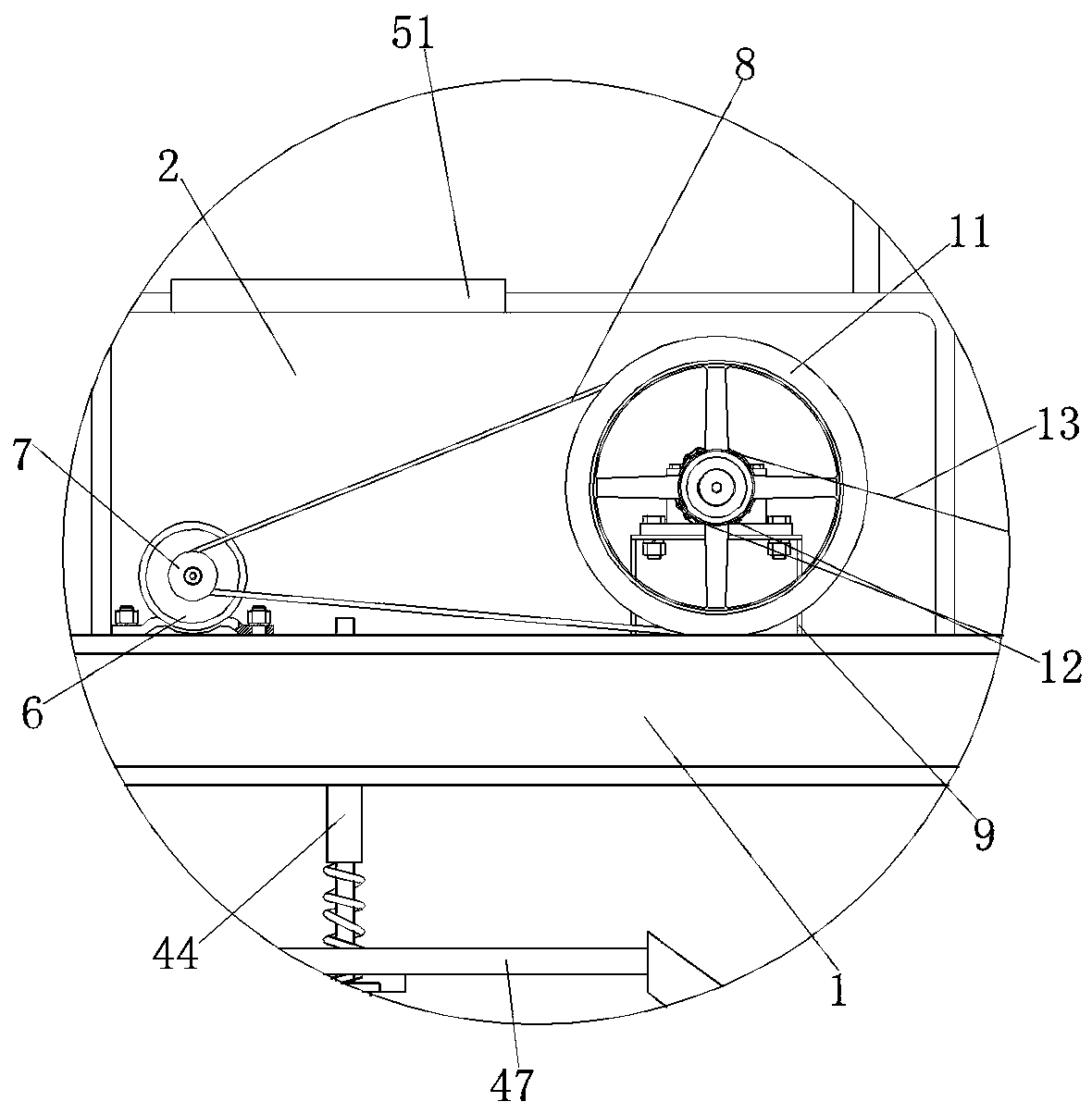

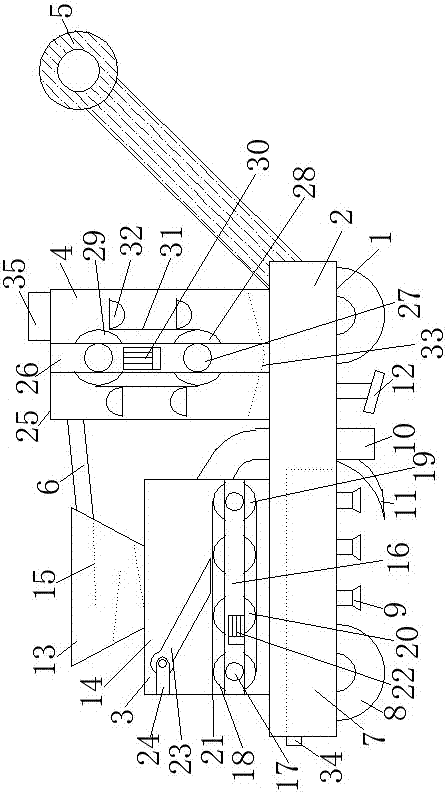

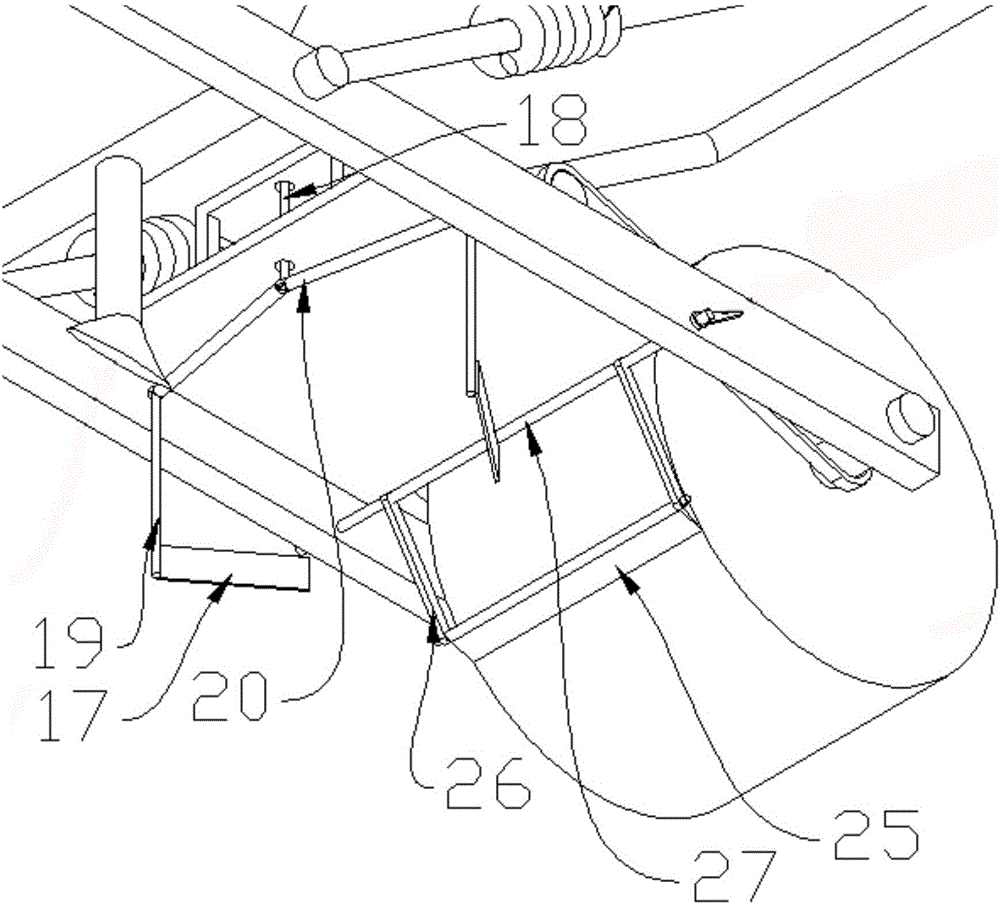

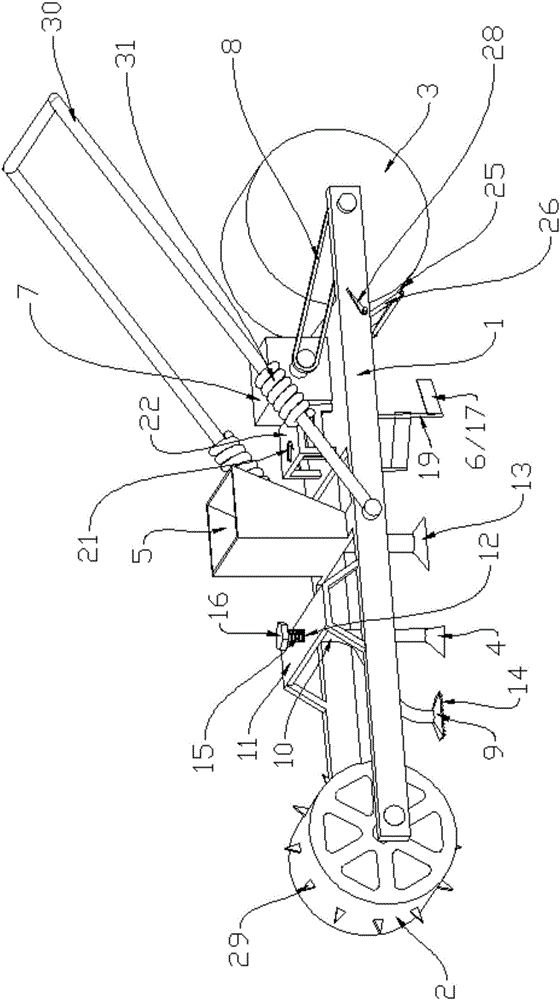

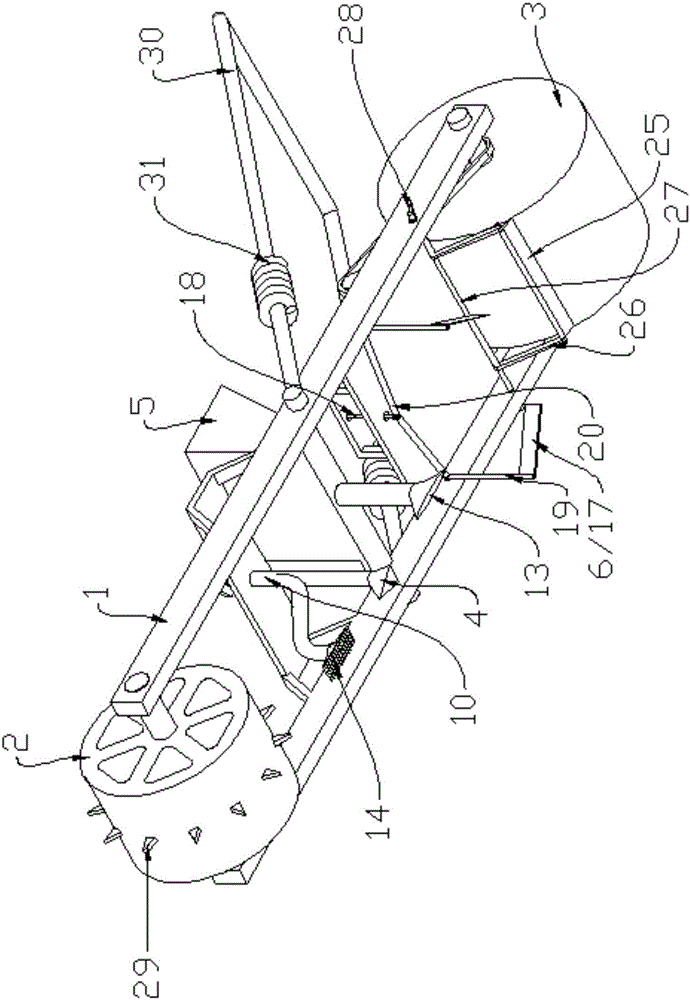

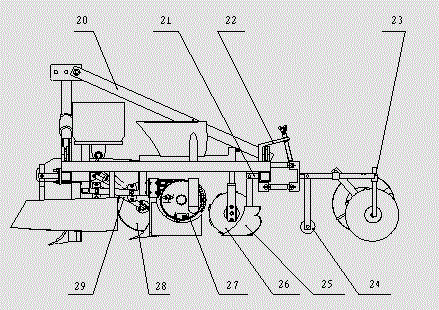

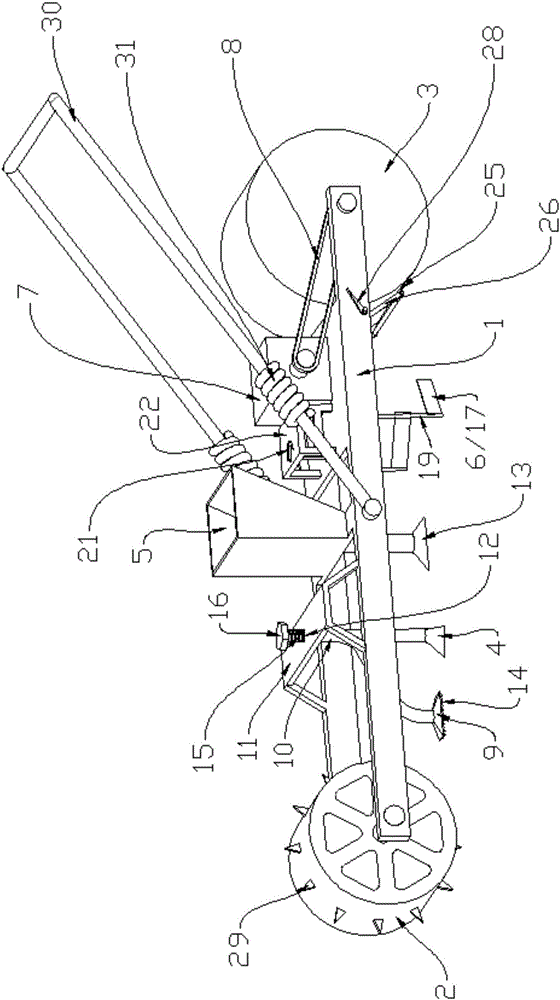

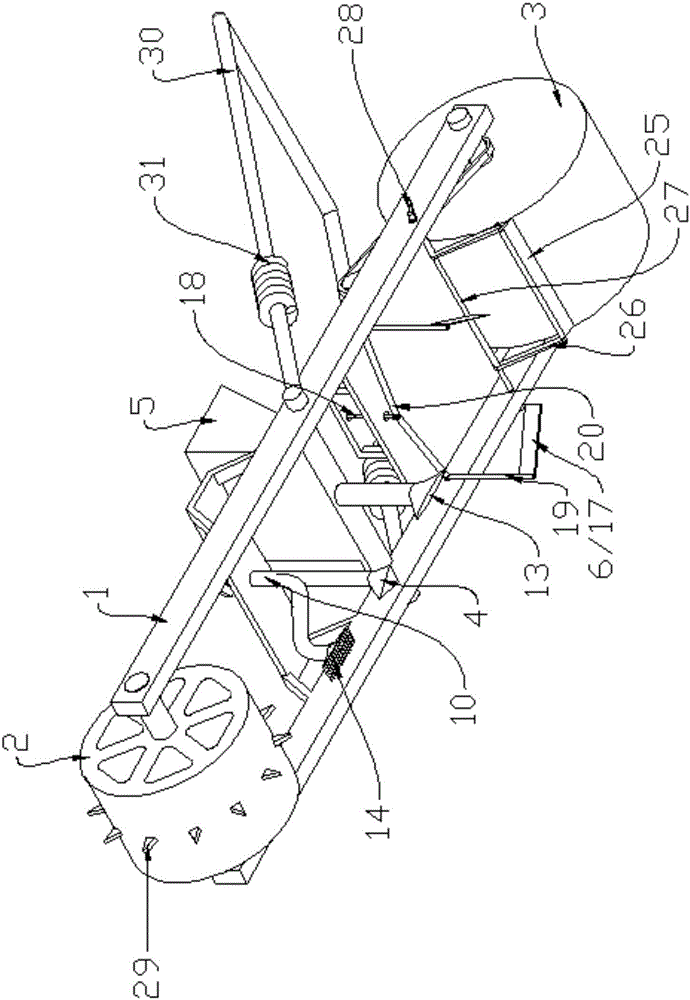

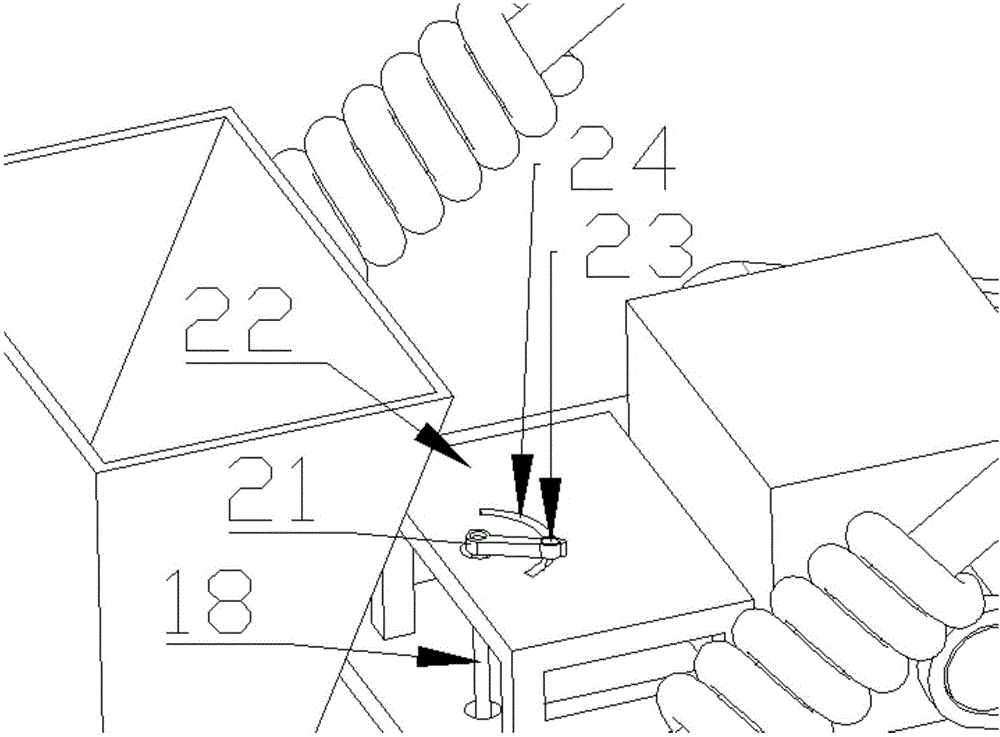

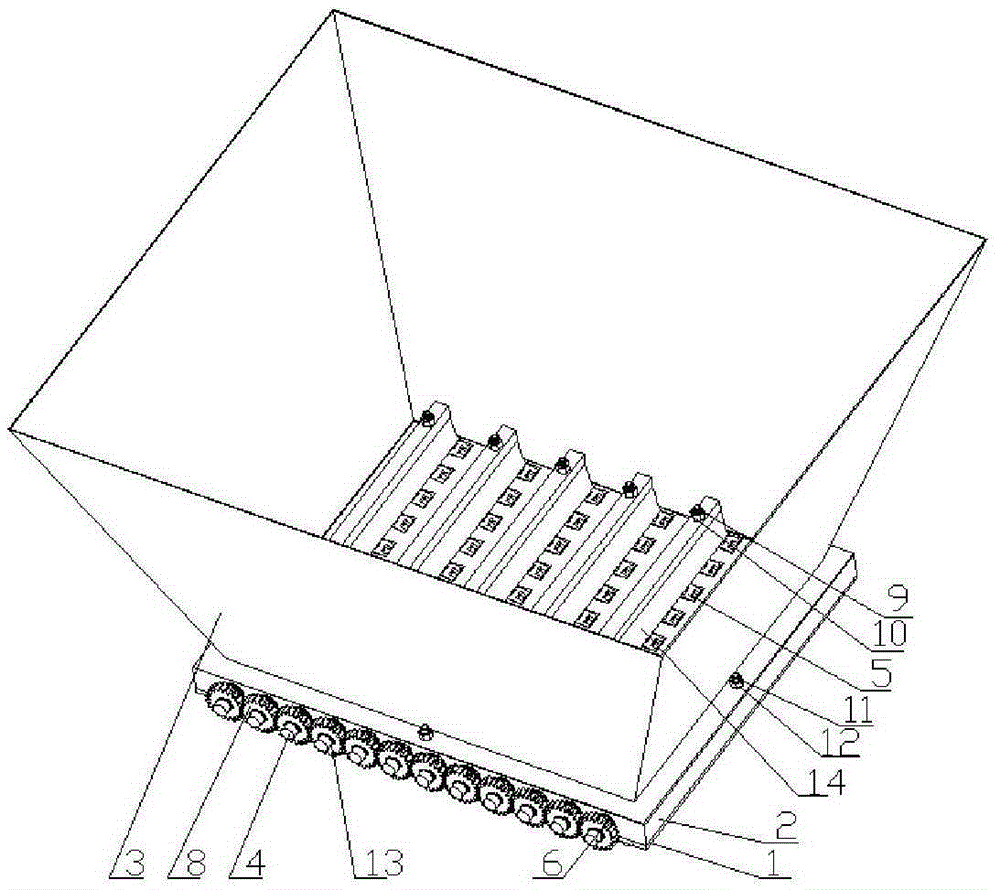

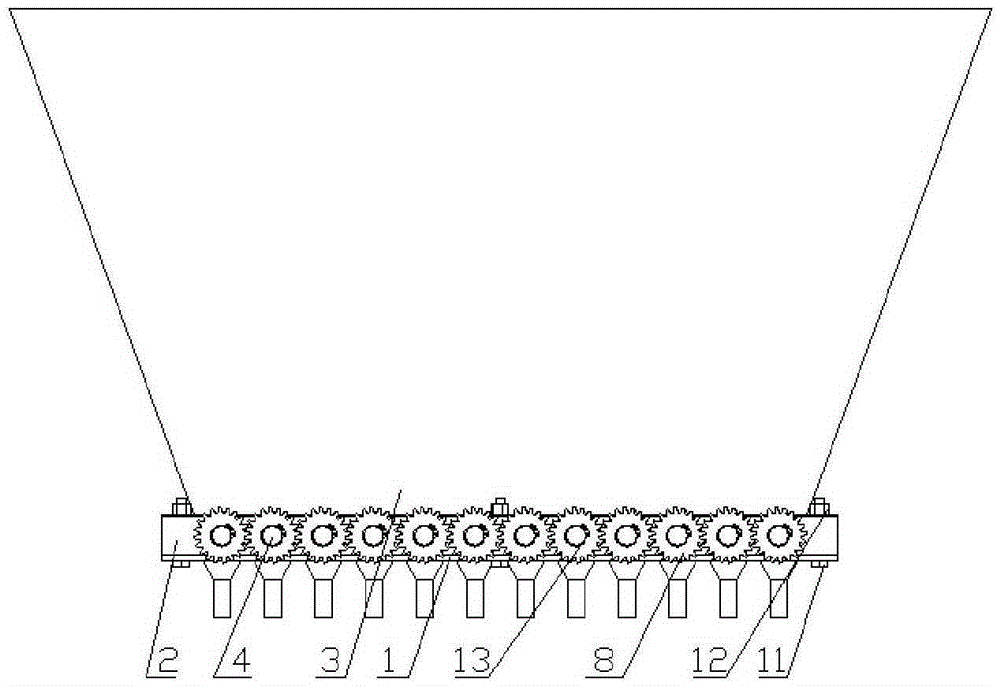

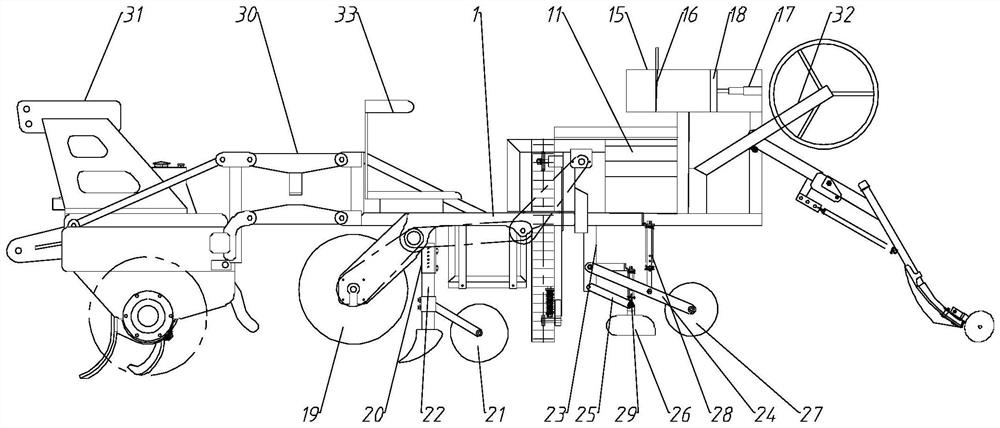

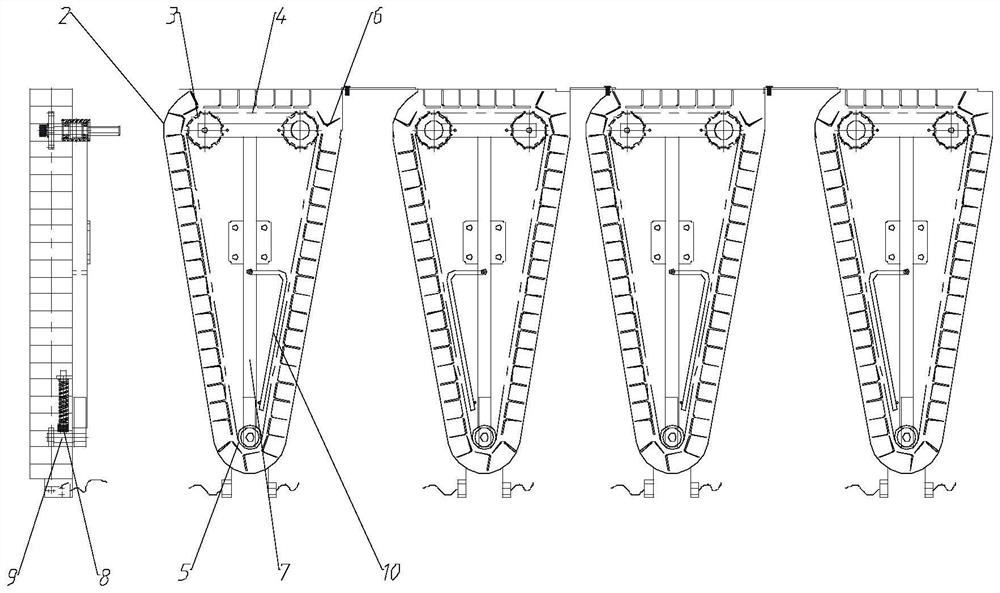

Anti-winding no-tillage fertilizing and seeding machine for wheat after rice in paddy field

The invention discloses a rice stubble and wheat anti-winding no-tillage fertilization seeder for paddy fields, comprising a suspension frame, a gear box assembly, a rotary tillage assembly, a ditching screw assembly and a suppression drainage assembly; the gear box assembly It is installed on the upper part of the suspension frame, and the top of the suspension frame is provided with a fertilizer sowing box and a sowing seed box. , the bottom of the chemical fertilizer spreading box is provided with a chemical fertilizer spreading bucket, and the chemical fertilizer spreading box is equipped with a hand wheel for adjusting the seeding rate of the chemical fertilizer spreading box; the spreading seed box is provided with a sowing transmission shaft. This rice stubble, wheat anti-winding, no-tillage and fertilization seeder for paddy fields can complete the work of crushing stalks, stubble removal, weeding, ditching, fertilization, sowing and suppression at one time, and at the same time, the ground is suppressed into a V shape during suppression. The topography allows water to flow into the trenches from both sides of the paddy field, which improves the survival rate of seeds, improves the efficiency of sowing work, and reduces the cost of sowing.

Owner:LUOYANG XINLE MACHINERY EQUIP

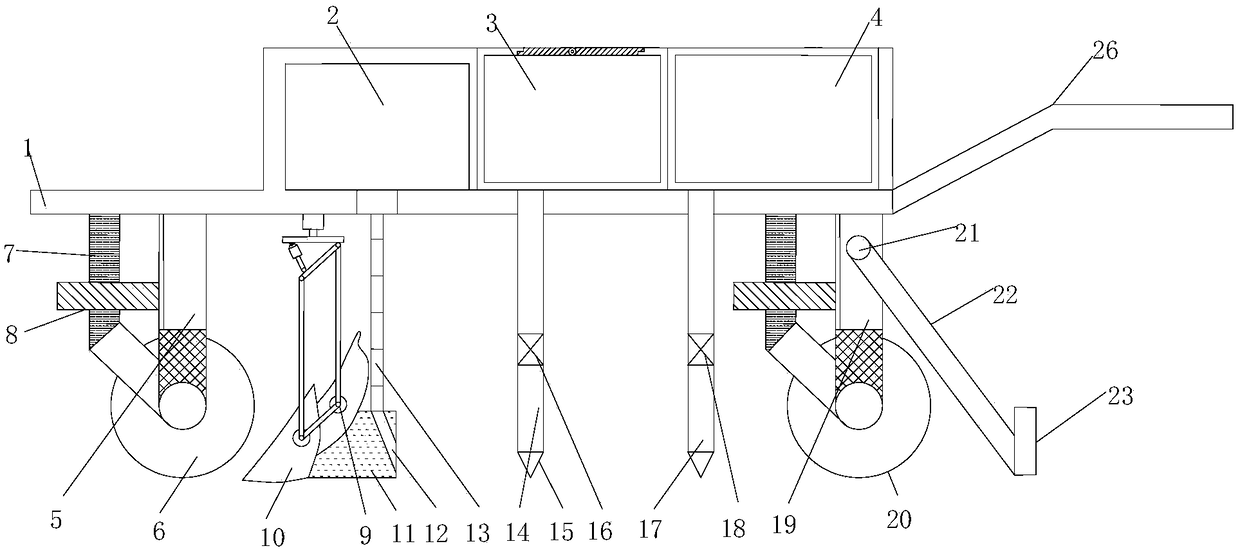

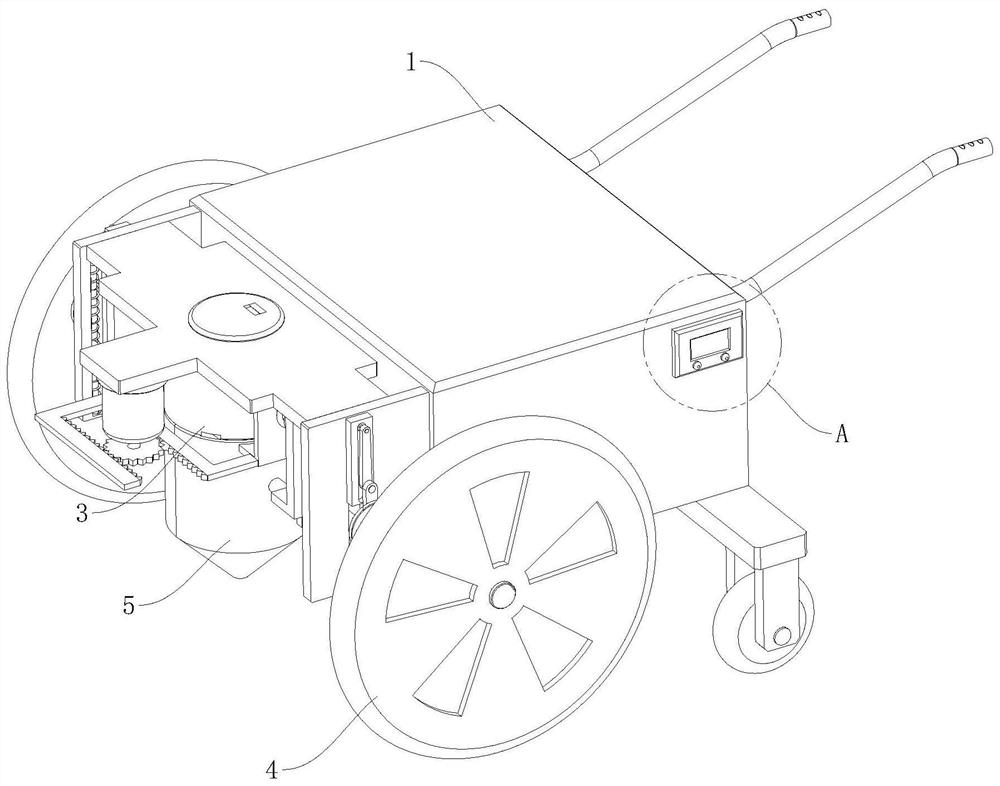

Seeding apparatus capable of integrally completing irrigation and fertilization

InactiveCN108811561AImprove seeding efficiencyAvoid meltingSpadesPloughsWater dischargeWater storage tank

The invention discloses seeding apparatus capable of integrally completing irrigation and fertilization. The apparatus comprises a supporting platform; a material storage tank, a fertilizer tank and awater storage tank are sequentially installed on the supporting platform, and a first roll wheel is connected with the lower part of the supporting platform through a first connecting rod; the side part of the first roll wheel is provided with an adjusting device, and a plowshare is installed at the bottom end of the adjusting device; a fertilizer discharging pipe is installed under the fertilizer tank, and a fertilizer discharging ball valve is installed on the fertilizer discharging pipe; a water discharging pipe is installed under the water storage tank, and a water discharging ball valveis installed on the water discharging pipe; and the side part of the water discharging pipe is provided with a second connecting rod, and a baffle is installed on the second connecting rod. Accordingto the apparatus disclosed by the invention, three processes of seeding, the fertilization and the irrigation are integrated in the same equipment, so that seeding efficiency of crops is improved, andseeding costs of planters are reduced; arrangement of the adjusting device realizes adjustment of a depth and angle of the plowshare in soil, and the apparatus is convenient for operation; and arrangement of a seal cover isolates contact of a fertilizer and water in air, and avoids fertilizer melting caused by long-time exposure of the fertilizer in the air.

Owner:芜湖拓达电子科技有限公司

Agricultural vegetable seeding machine

InactiveCN108738538AImprove mobile efficiencyReduce shipping costsFertiliser and seeding apparatusFertiliser equipmentsAgricultural engineeringUltimate tensile strength

The invention discloses an agricultural vegetable seeding machine which comprises a vehicle body, wherein a traction rod is arranged on the left side of the top of the vehicle body, a driving box is arranged at the top of the left side of the vehicle body, a transmission box is arranged on the right side of the driving box, the transmission box is connected with the vehicle body, a fertilizer boxis arranged on the right side of the transmission box, and the fertilizer box is connected with the vehicle body. According to the agricultural vegetable seeding machine disclosed by the invention, the driving box, the transmission box, the fertilizer box and a seeding box are matched; ditching, seeding, fertilizing and backfilling are integrated on one set of equipment; the agricultural vegetableseeding machine has multiple functions and wide application; working strength of mutually ditching, seeding, fertilizing and backfilling of workers is reduced, and physical fatigue of the workers isovercome; the agricultural vegetable seeding machine has the advantages of simpleness in operation, convenience in movement and transportation, low transportation cost and suitability for being popularized and applied; by means of the agricultural vegetable seeding machine, work efficiency of workers is improved, planting manual cost is reduced, and a yield is improved.

Owner:张程翔

Agricultural sowing device

InactiveCN107223391AReduce limitationsEasy sowingPlantingWatering devicesElectric machineAgricultural engineering

The invention discloses an agricultural seeding device, which includes a device body, the device body includes a base, and the top of the base is respectively provided with a feeding mechanism, a feeding mechanism and a push handle, wherein the feeding mechanism is connected to the One side of the unloading mechanism. The second rotating motor in the conveying mechanism matches the second transmission belt under the action of the conveying sheet, so that the material in the conveying mechanism can be transported to the lower hopper through the connecting pipe, and the lower hopper is coordinated by several groups of first slide plates. , so that the material is transported to the unloading chamber. In addition, the first rotating motor in the unloading chamber cooperates with the first transmission belt and the sloping plate to transport the material into the unloading pipe. In addition, the base is matched with the water tank and the furrow plow on the pusher to effectively treat the soil. Ditching is convenient for sowing, and the soil-covering sheet is convenient for covering soil after sowing, which makes the operation easy, the sowing cost is low, and can adapt to the sowing requirements in different environments, reducing the limitation of the use of the sowing device.

Owner:CHENGDU PUJIANG KEXIAN TECH

Efficient multifunctional peanut film covering seeding machine

PendingCN109041621AImprove structural stabilityEasy to installSpadesWatering devicesAgricultural engineeringUltimate tensile strength

The invention discloses an efficient multifunctional peanut film covering seeding machine. The efficient multifunctional peanut film covering seeding machine comprises a machine frame, a soil flattingauger, a fertilization device, a ridging device, a seeding device, a pipe laying device, a pesticide spraying device, a film covering device and a soil covering compacting device. The efficient multifunctional peanut film covering seeding machine has the advantages that designing is reasonable, using is convenient and rapid, the seeding efficiency of peanuts is effectively improved, soil loosening, ditching and fertilizing, ridging, seeding, film covering, pesticide spraying and perforating and soil covering can be completed at a time, seeding costs are lowered effectively, labor intensity islowered, the seeding efficiency is improved, and using value is quite high.

Owner:郑州市双丰机械制造有限公司

Seeder capable of automatically removing soil

The invention provides a seeder capable of automatically removing soil. The seeder comprises a rack, a land wheel and a press wheel. The land wheel is arranged on the front end of the rack in a rotation mode while the press wheel is arranged on the back end of the rack in a rotation mode. The back of the land wheel is provided with a furrow opener, a seeding outlet and a covering device in sequence. The furrow opener and the covering device are fixed on the rack. The seeding outlet communicates with a sowing box fixed on the rack. The rack is provided with an engine which is connected with the press wheel through a belt. Below the rack, a scraper is arranged in front of the press wheel which cooperates with the scraper. The scraper is connected with a torsion shaft fixed with the rack through a joint lever. The end of the torsion shaft is fixedly sleeved with a torsion handle. The seeder has the advantages of automatically removing soil on the press wheel and reducing labor cost.

Owner:TIANJIN JIABANGNUO TECH CO LTD

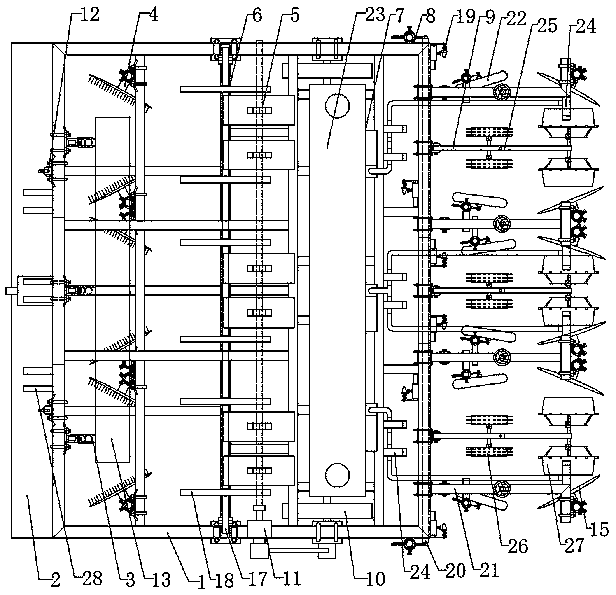

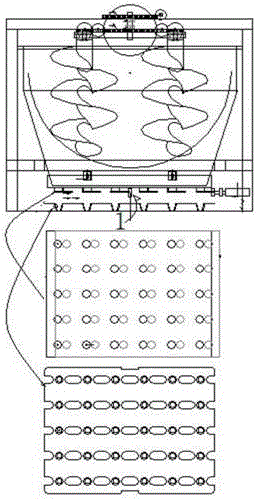

Full-automatic sowing-to-harvesting completion system for small-leaf vegetables

InactiveCN106233887AImprove product qualityReduce seeding costsSpadesPlantingGreenhouseMaterial resources

The invention discloses a full-automatic sowing-to-harvesting completion system for small-leaf vegetables. The full-automatic sowing-to-harvesting completion system for the small-leaf vegetables comprises the following steps: 1) automatically filling soil, putting a seeding hole tray into a soil covering device to perform automatic soil filling, wherein the soil covering device is connected with a surplus soil collecting device and a soil conveying device; 2) performing automatic hole pressing; 3) performing dibble seeding of seeds; 5) conveying the seeds to a field or a greenhouse; 6) performing self-propelled laying; and 7) performing automatic harvesting. The full-automatic sowing-to-harvesting completion system achieves double-rail mini-tiller soil turning, automatic laying of the seeding hole tray, automatic watering, automatic fertilization, connection to a vegetable harvesting and collecting device, multi-system operation application and the like, or the double-rail type multi-application, so that an automatic system operation of vegetable sowing is further completed, manpower and material resources are saved, and an automatic and intelligent rapid sowing system is promoted.

Owner:黄智灏

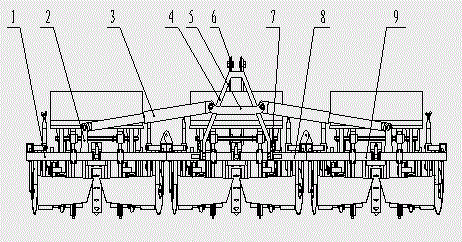

Folding type cotton film-mulching seeder based on machine-harvested cotton

InactiveCN105027759AReduce widthImprove road passabilityPlantingFurrow making/coveringAgricultural engineeringSeedling

The invention relates to a folding type cotton film-mulching seeder based on machine-harvested cotton. The folding type cotton film-mulching seeder comprises a suspension support. A machine frame is suspended to the suspension support through a suspension connecting plate. An upper connection lifting lug is arranged on the top of the suspension support. A lower connection lifting lug is arranged on a rear beam of the machine frame. A diagonal draw bar is connected between the upper connection lifting lug and the lower connection lifting lug. The two sides of the machine frame are provided with a left side machine frame body and a right side machine frame body through machine frame connecting pins respectively. The upper ends of two hydraulic oil cylinders are connected to a cross beam of the suspension support, and the lower ends of the two hydraulic oil cylinders are connected to the left side machine frame body and the right side machine frame body through oil cylinder connection lifting lugs. A seed discharging and fertilization driving wheel is connected to a front cross beam of a profiling fertilization seeding monomer through a driving wheel single arm, and connected with a fertilizer discharger and a seed discharger through a chain. A film-mulching device is suspended on the rear beam of the machine frame through a film-mulching profiling mechanism. The working efficiency is improved by more than 35%, wide operation can be achieved, the road passing ability is good, space is reserved for cotton seedlings after seeding, the seeding depth consistency reaches more than 99%, and the seeding cost is reduced by 30-40%.

Owner:滨州市农业机械化科学研究所

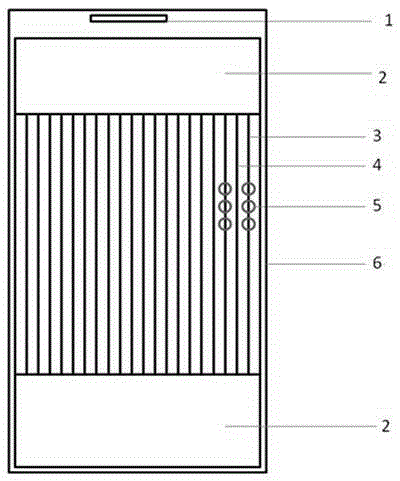

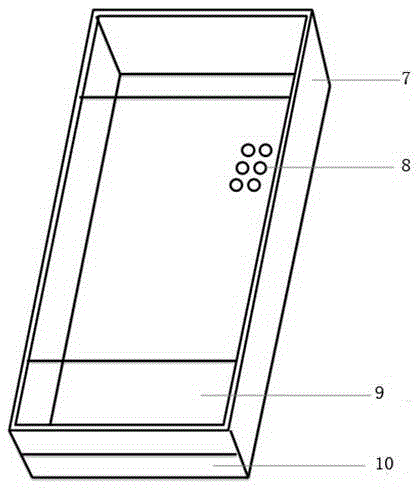

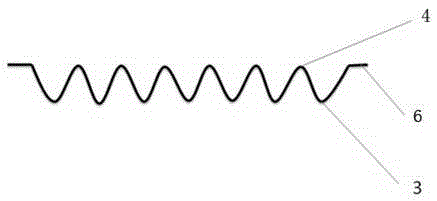

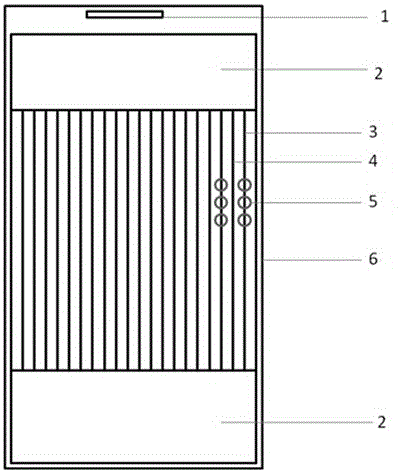

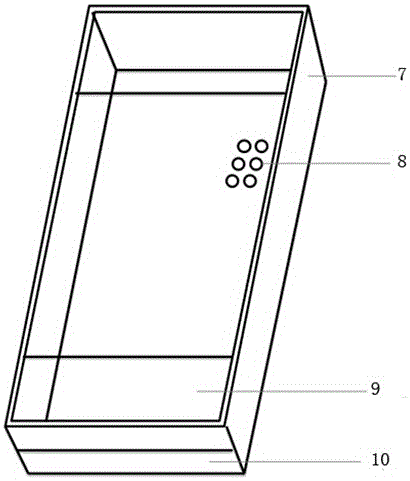

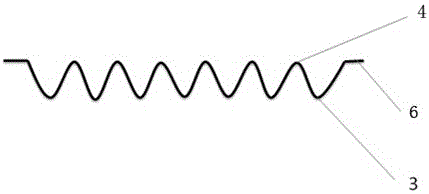

High-efficiency accurate-measurement positioning seeding method

ActiveCN105340434AEfficient and precise positioningImprove sowing qualitySeed depositing seeder partsRegular seed deposition machinesWave shapeEngineering

The invention relates to a high-efficiency accurate-measurement positioning seeding device and a method for seeding employing the same. The seeding device is composed of two structures A and B. The structure A can be placed in the structure B, and can move in the structure B. The middle part of the structure A is a seeding region. Seed holding tanks are arranged at two ends of the seeding region. One end of the structure A extends outwards and forms a handle. The cross section of the seeding region of the structure A is wave-shaped. A plurality of seeding holes are arranged at the wave-shaped valley bottoms. When a plate A is placed in the structure B, Seed passing holes are arranged in positions, corresponding to the seeding holes of the structure A, of the structure B. the seed passing holes correspond with the seeding holes one by one, and deviate towards one side by about half hole pitch relative to the seeding holes. The sizes of the seed passing holes are larger than that of the seeding holes. The provided seeding device is employed for seeding, high-efficiency accurate-measurement positioning can be achieved, the seeding quality and efficiency are raised, the seeding cost is lowered, convenience is provided for seedling growing production, and the provided seeding device is suitable for large-scale popularization.

Owner:YANGZHOU UNIV

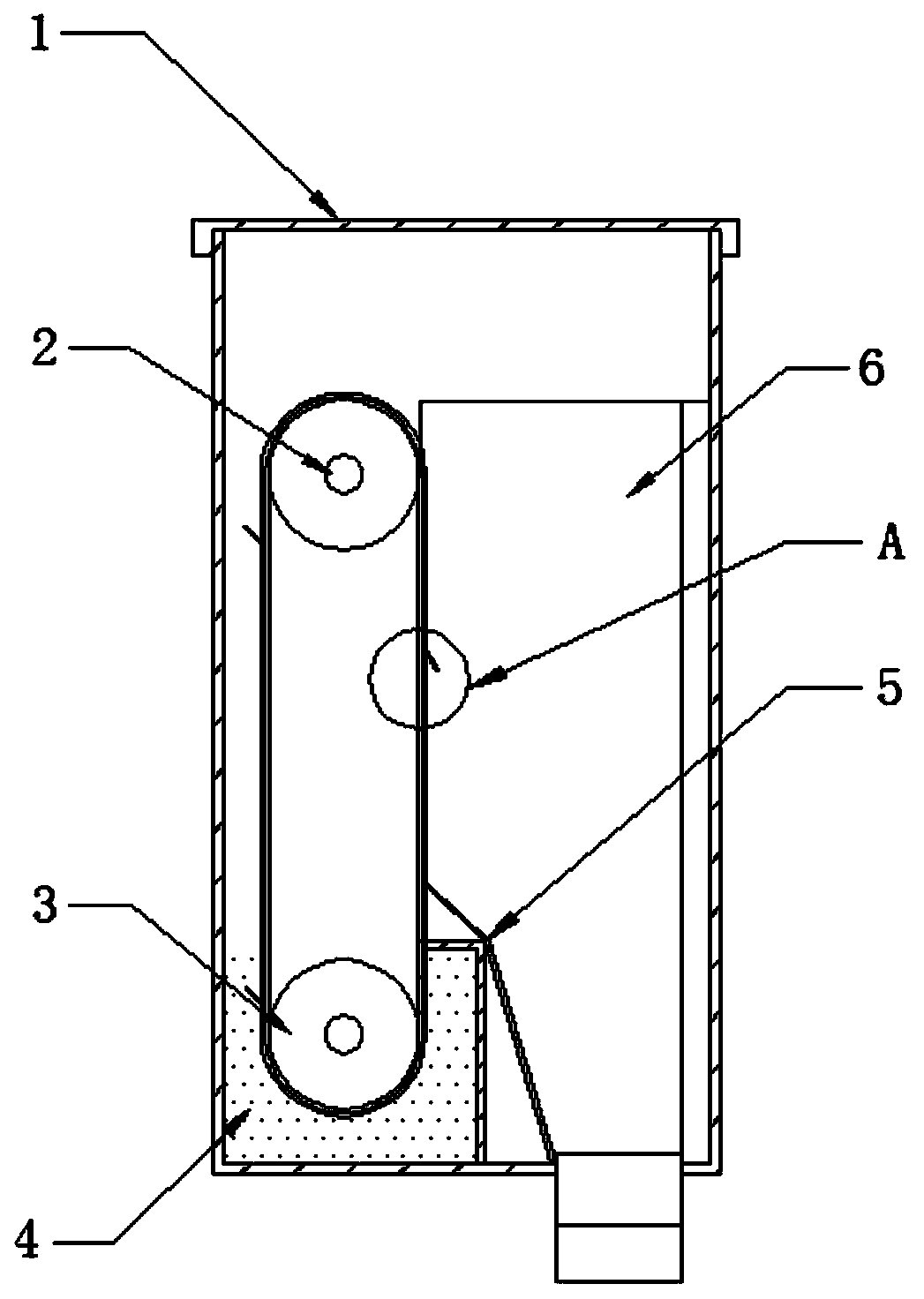

Handheld seeder

The invention relates to a handheld seeder, which comprises a shell, a seed box, a driving shaft, a driven shaft, a belt, a seed sowing belt, a rocker, a baffle and division plates. The lower end of the shell is provided with a seed sowing mouth, and the seed box is arranged in the shell at the front side of the lower end; the driving shaft and the driven shaft at intervals are arranged at the front side in the shell at internal, the driving shaft extends out of the shell and is connected with the rocker, and the driven shaft is located in the seed box; the belt surrounds between the driving shaft and the driven shaft; the seed sowing belt is located at the outer side of the belt, and provided with a seed groove; the baffle is located at the rear side in the shell and behind the seed sowing belt; and the division plates are arranged at the left and right sides of the seed sowing belt and the baffle, and has the lower end extending to the seed sowing mouth. The invention has the advantages of simple structure and convenience for usage; because the seed sowing belt and the baffle plate can be disassembled, and the seeder is applicable for sowings seeds with different sizes in different types of plug trays by adjusting the the number and position of the seed sowing belt and partition plates. The invention expands the scope of application of the handheld seeder and reduces the sowing cost.

Owner:TONGJI UNIV

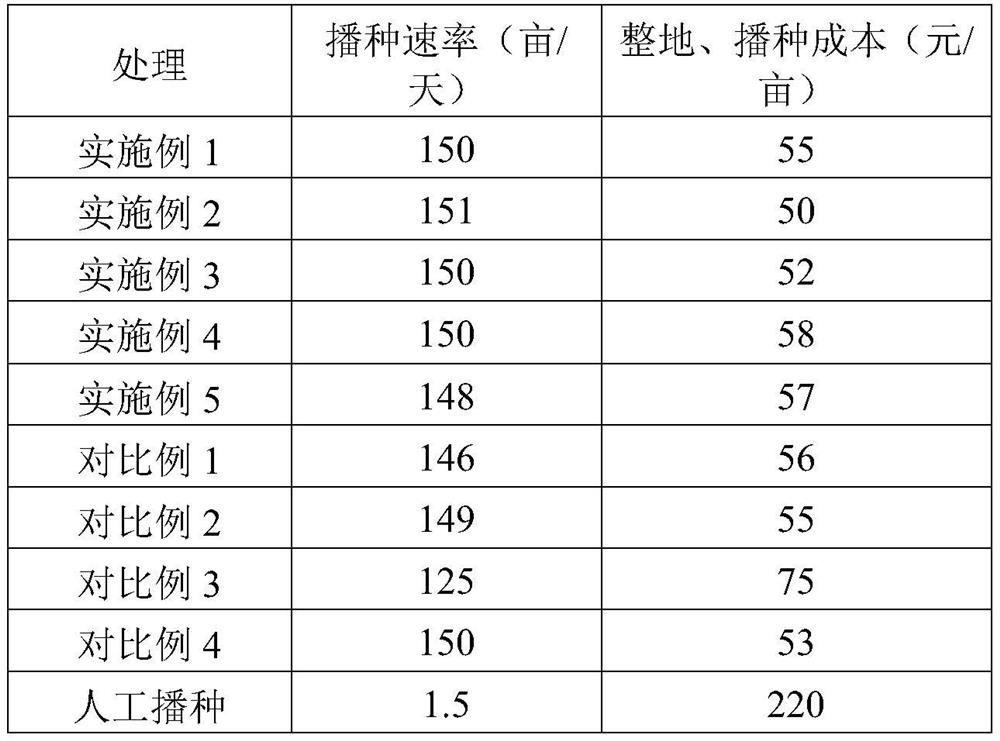

Mechanized efficient seeding method suitable for chenopodium quinoa in coastal sandy saline-alkali soil

PendingCN113273457AImprove seeding efficiencyGuaranteed emergence rateSeed and root treatmentCereal cultivationSeederSoil science

The invention provides a mechanized efficient seeding method suitable for chenopodium quinoa in coastal sandy saline-alkali soil. A large-scale seeding machine integrating ditching and seeding is utilized, parameters of the seeding machine are controlled, such that mechanical seeding of chenopodium quinoa in coastal sandy saline-alkali soil is realized, and the seeding efficiency of chenopodium quinoa is improved while a seedling emergence rate is ensured. Aiming at characteristics of high sand content and high underground water level of coastal sandy saline-alkali soil, the seeding machine integrating ditching and seeding is adopted, an advancing speed and a seeding speed of the seeding machine are controlled, such that the seeding efficiency is improved, the seeding cost is reduced, resource waste is reduced, coastal saline-alkali soil resources are fully utilized, and a foundation is laid for characteristic agricultural development in coastal regions.

Owner:江苏省沿海开发(东台)有限公司

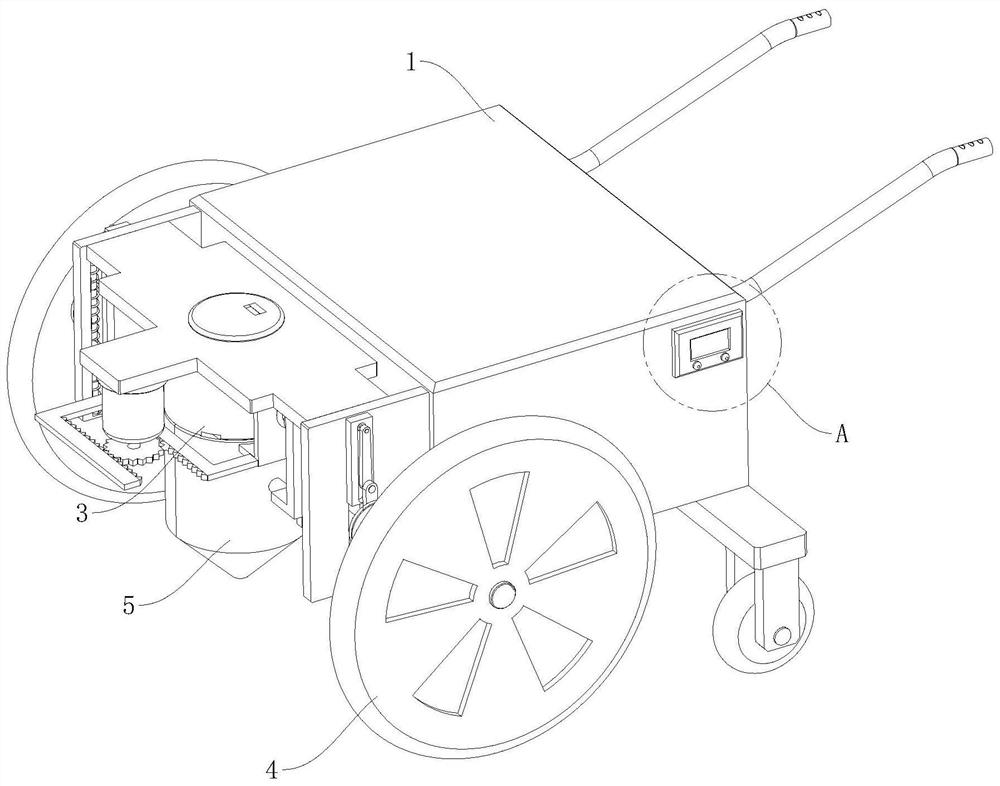

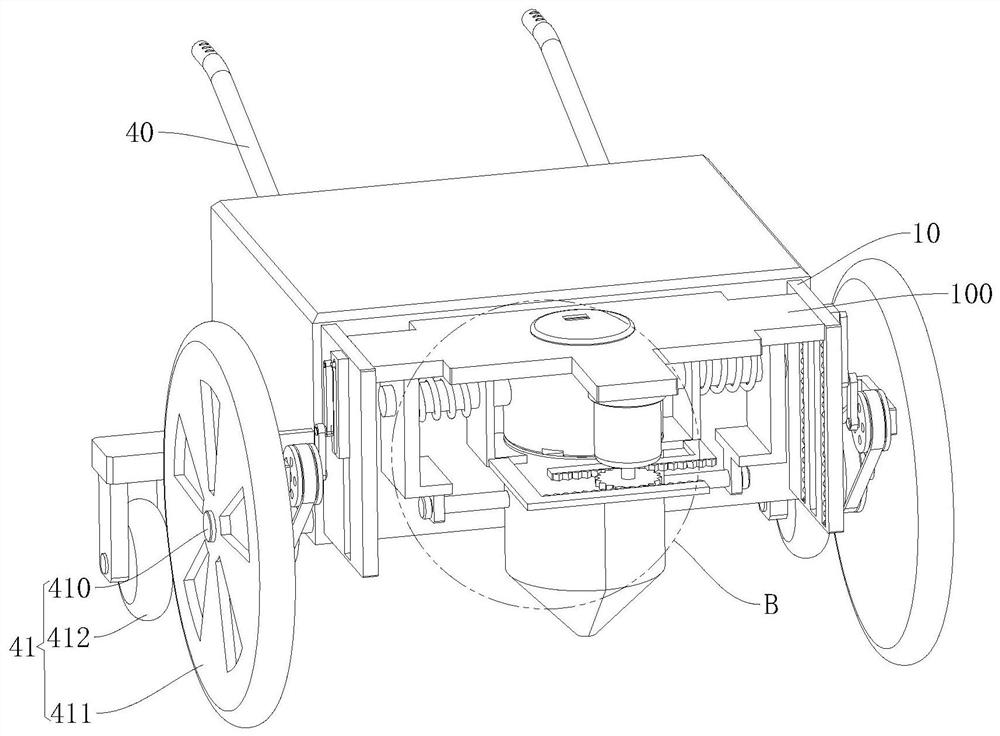

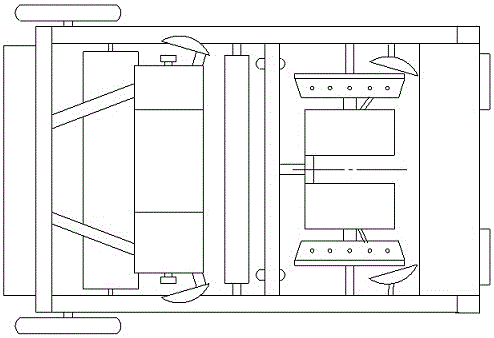

Agricultural sowing equipment

ActiveCN112772058AReduce labor intensitySame shadePlantingDibble seedersAgricultural scienceAgricultural engineering

The invention relates to the field of agricultural machinery, in particular to agricultural sowing equipment. The equipment comprises a vehicle body, a controller, a sowing mechanism, walking mechanisms and a soil expanding mechanism, the walking mechanisms are arranged on the two sides of the vehicle body to support the equipment to walk, and each walking mechanism comprises a push handle and a rolling assembly. The soil expanding mechanism is arranged at the bottom of the sowing mechanism and used for digging holes, the soil expanding mechanism comprises a driving assembly, two conical digging shovels, two transverse sliding assemblies and two longitudinal sliding assemblies, the sowing mechanism is arranged on the outer wall of the vehicle body and used for sowing seeds, and the sowing mechanism comprises a feeding assembly and a sensing assembly. The driving assembly, the sensing assembly and the controller are all electrically connected, according to the equipment, manual work is replaced, the seeding efficiency is high, quantitative seeding can be achieved, waste is avoided, the labor intensity is small, meanwhile, fixed-distance seeding can be achieved, crop growth and subsequent seedling transplanting are facilitated, and the seeding cost is conveniently reduced.

Owner:芜湖星之原工业设计有限公司

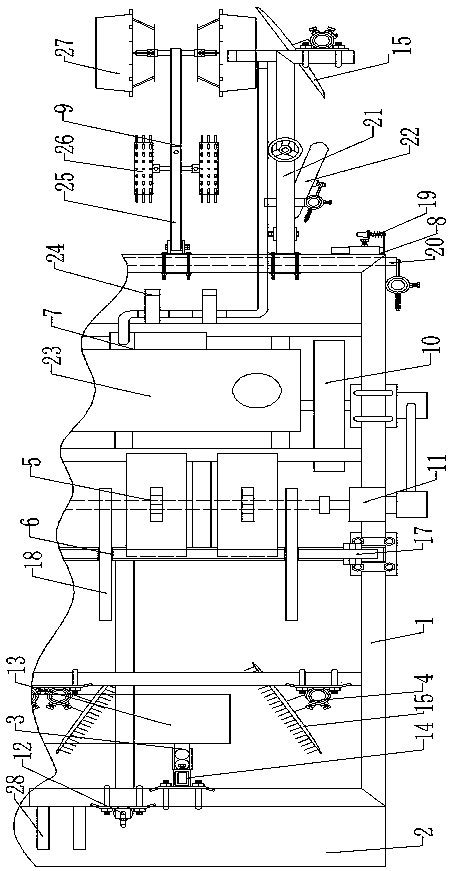

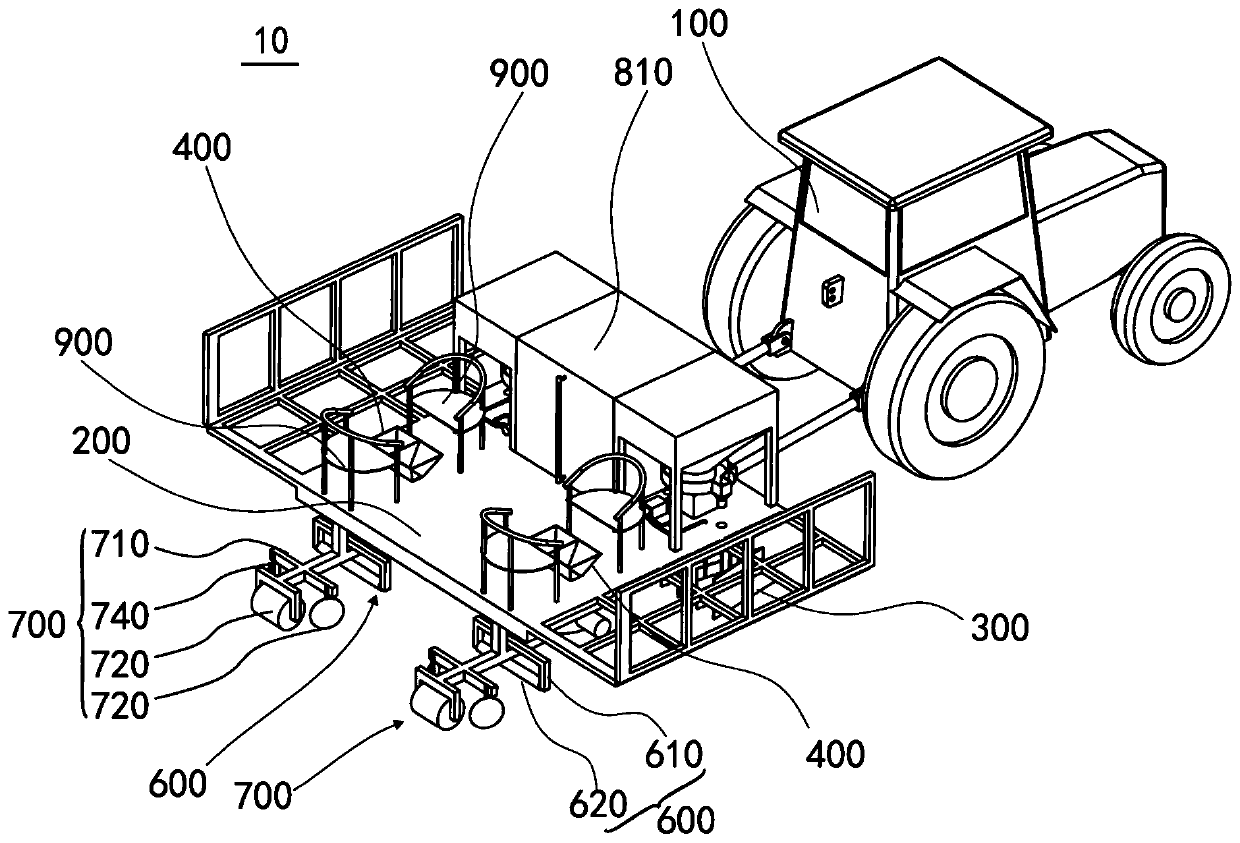

Sowing machine

PendingCN110169222AGuaranteed emergence rateImprove seeding efficiencySpadesPloughsAgricultural engineeringMulch

The invention discloses a sowing machine, which comprises a traction device, a sowing platform, ridge breaking devices, seeding devices, fertilizer applying devices, mulching devices, earth-up devicesand a sprinkling device. The traction device is connected to the sowing platform, and the sowing platform is provided with seeding passages, sprinkling passages and fertilizer applying passages sequentially along the advancing direction of the traction device. The ridge breaking devices are connected to the sowing platform, the seeding devices are arranged on the sowing platform and communicatedwith the seeding passages, the fertilizer applying devices are arranged on the sowing platform and communicated with the fertilizer applying passages, the mulching devices are connected to the sowingplatform and positioned under the sowing platform to mulch furrows, the earth-up devices are connected to the sowing platform and positioned under the sowing platform, the sprinkling device is arranged on the sowing platform, and the ridge breaking devices, the mulching devices and the earth-up devices are arranged sequentially along the advancing direction. The sowing machine has advantages thattimely sprinkling in sowing and low sprinkling cost are realized, and the emergence rate of crops is effectively guaranteed.

Owner:GUANGDONG PROVINCIAL BIOENGINEERING INST (GUANGZHOU SUGARCANE IND RES INST)

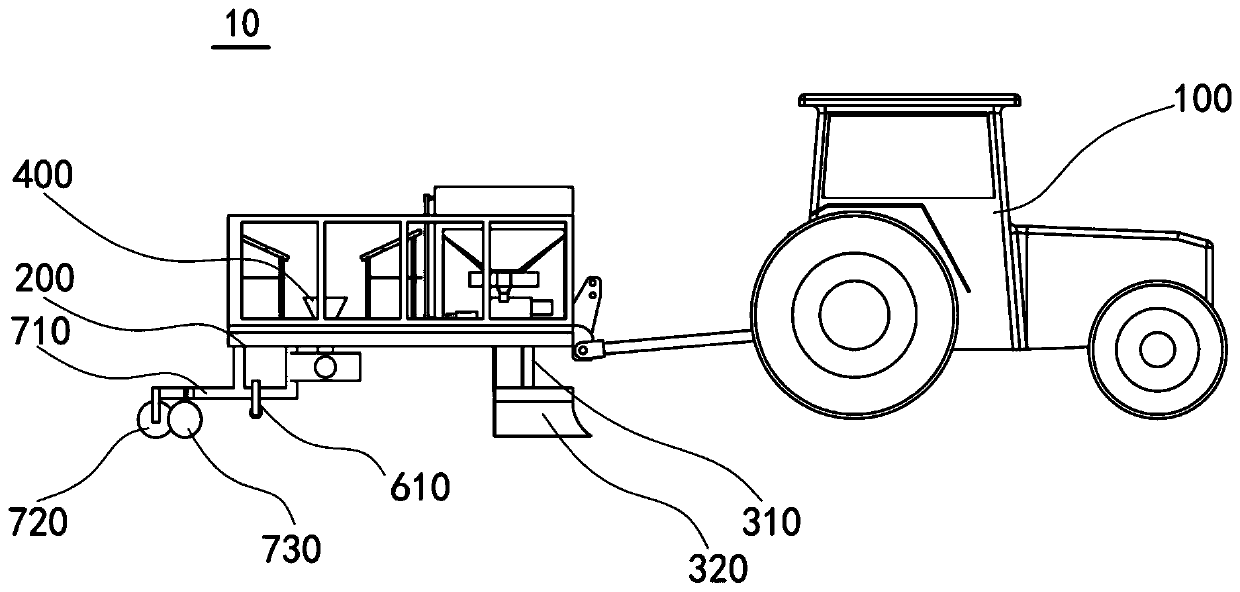

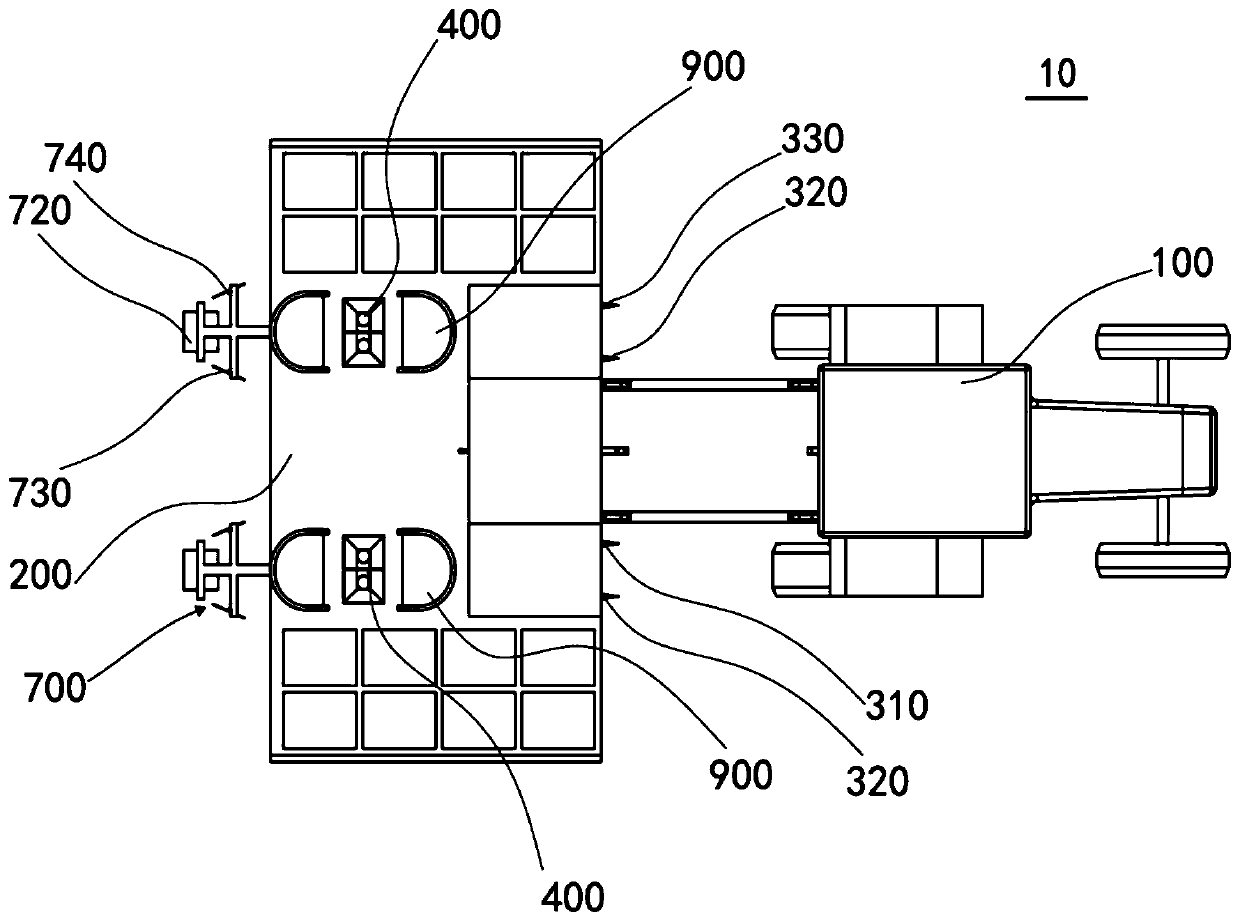

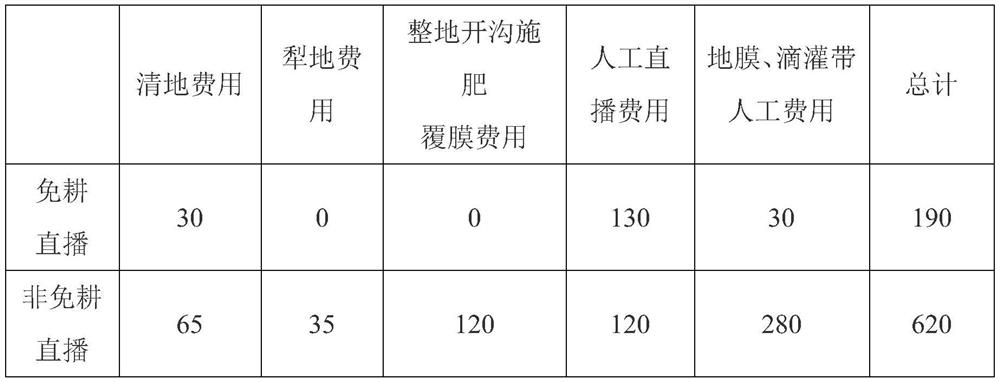

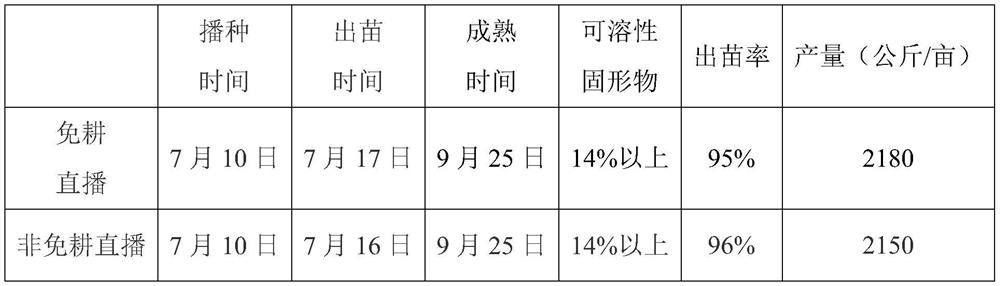

No-tillage drip irrigation planting method for autumn Hami melons

PendingCN113229066AReduce evaporationSimple structureClimate change adaptationWatering devicesDrip irrigationPlastic mulch

The invention relates to a no-tillage drip irrigation planting method for autumn Hami melons. The no-tillage drip irrigation planting method comprises the following steps that (1), soil preparation is carried out, specifically, spring melon seedlings uniformly cover the earth surface outside a planting belt; (2), staggered direct seeding is carried out, specifically, spring Hami melon seeding holes are staggered between July 5 and July 20, punching and directly seeding are carried out on a spring stubble mulching film, seeds are covered with fine soil, and the mulching film is pressed and covered; (3), according to a cultivation mode, the narrow row spacing of the Hami melons is 0.5-0.6 m, the average row spacing of the wide row and the narrow row is 3.2-3.5 m, and two drip irrigation belts are arranged under the mulching film; (4), according to an irrigation mode, water is dripped for 2-4 hours in the morning and evening every day after sowing until the seedlings emerge to full seedlings; (5), field management is carried out, specifically, seedling hardening is carried out for 12-15 days, double-vine pruning is carried out, vines are pressed at proper time, melons are selected, the melons are padded, the melons are interplanted, water and fertilizer integrated management is carried out, and comprehensive prevention and control is carried out on plant diseases and insect pests; and (6), harvesting is carried out, specifically, when soluble solids in the center of the Hami melons reach 14% or above, harvesting is carried out. According to the no-tillage drip irrigation planting method for the autumn Hami melons, the production cost is saved, economic benefits are increased, white pollution is reduced, and ecological benefits are obvious.

Owner:TULUFAN AGRI TECH EXTENSION CENT

Seeding machine convenient to reverse to cover soil

InactiveCN106717200AUniformity of buried depthIncrease productionSpadesPlantingSeederAgricultural engineering

The invention provides a seeding machine convenient to reverse to cover soil. The seeding machine comprises a rack, a ground wheel and a pressing wheel, wherein the ground wheel and the pressing wheel are respectively installed on front and back ends of the rack; a furrow opener, a seed feed opening and a covering device are arranged behind the ground wheel in sequence; the covering device comprises two scrapers symmetrically arranged on the seeding machine, and the two scrapers are further connected with a reversing mechanism. The seeding machine provided by the invention can effectively improve the soil covering efficiency by means of the adjustment of the reversing mechanism.

Owner:TIANJIN JIABANGNUO TECH CO LTD

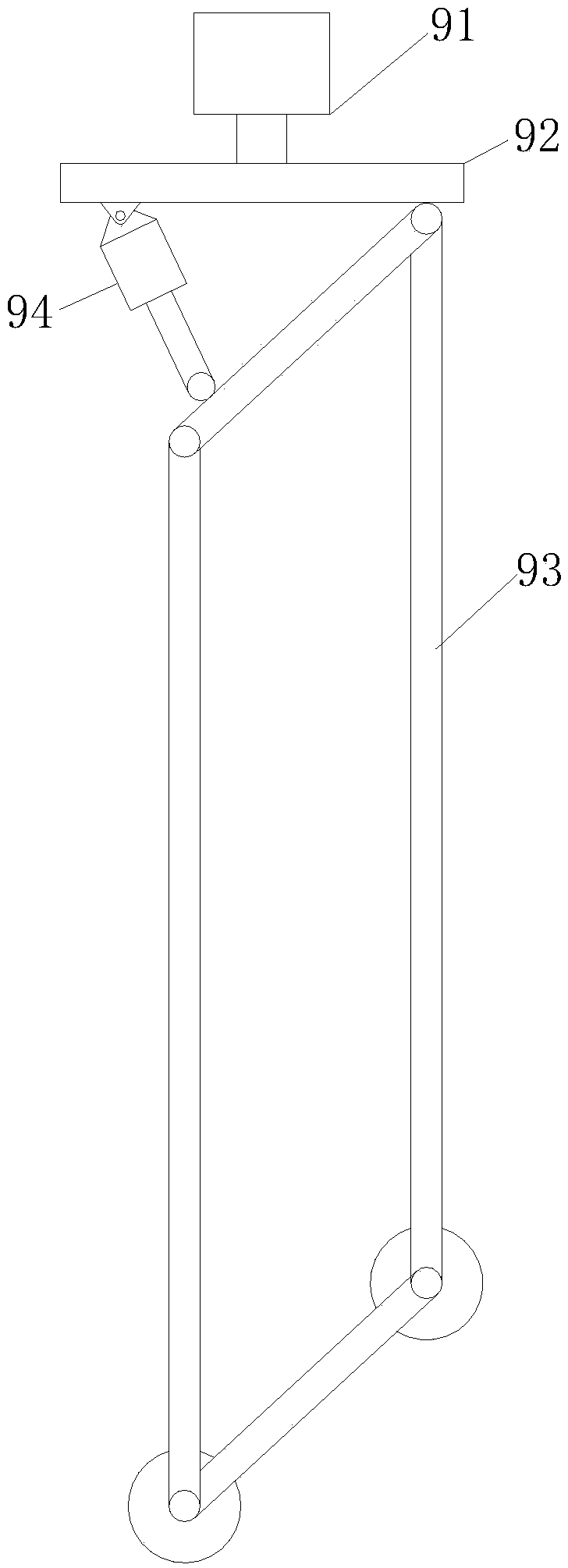

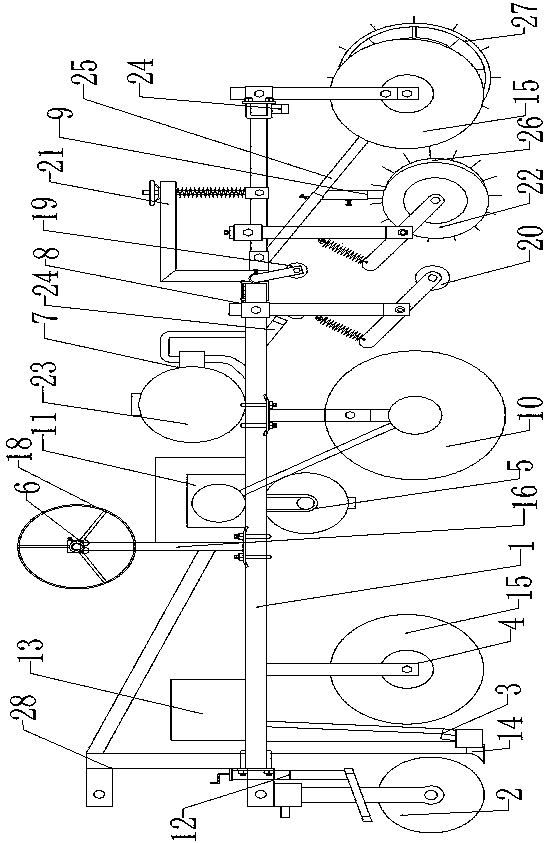

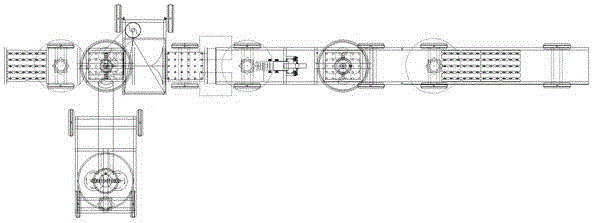

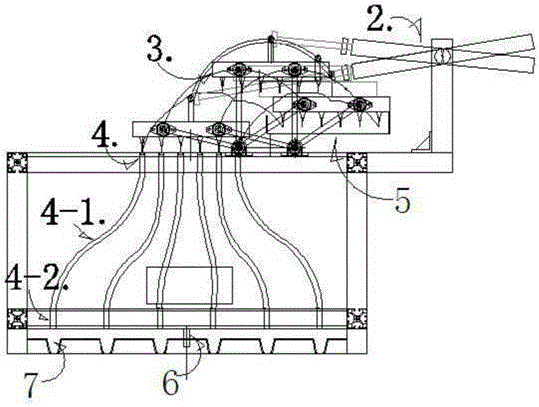

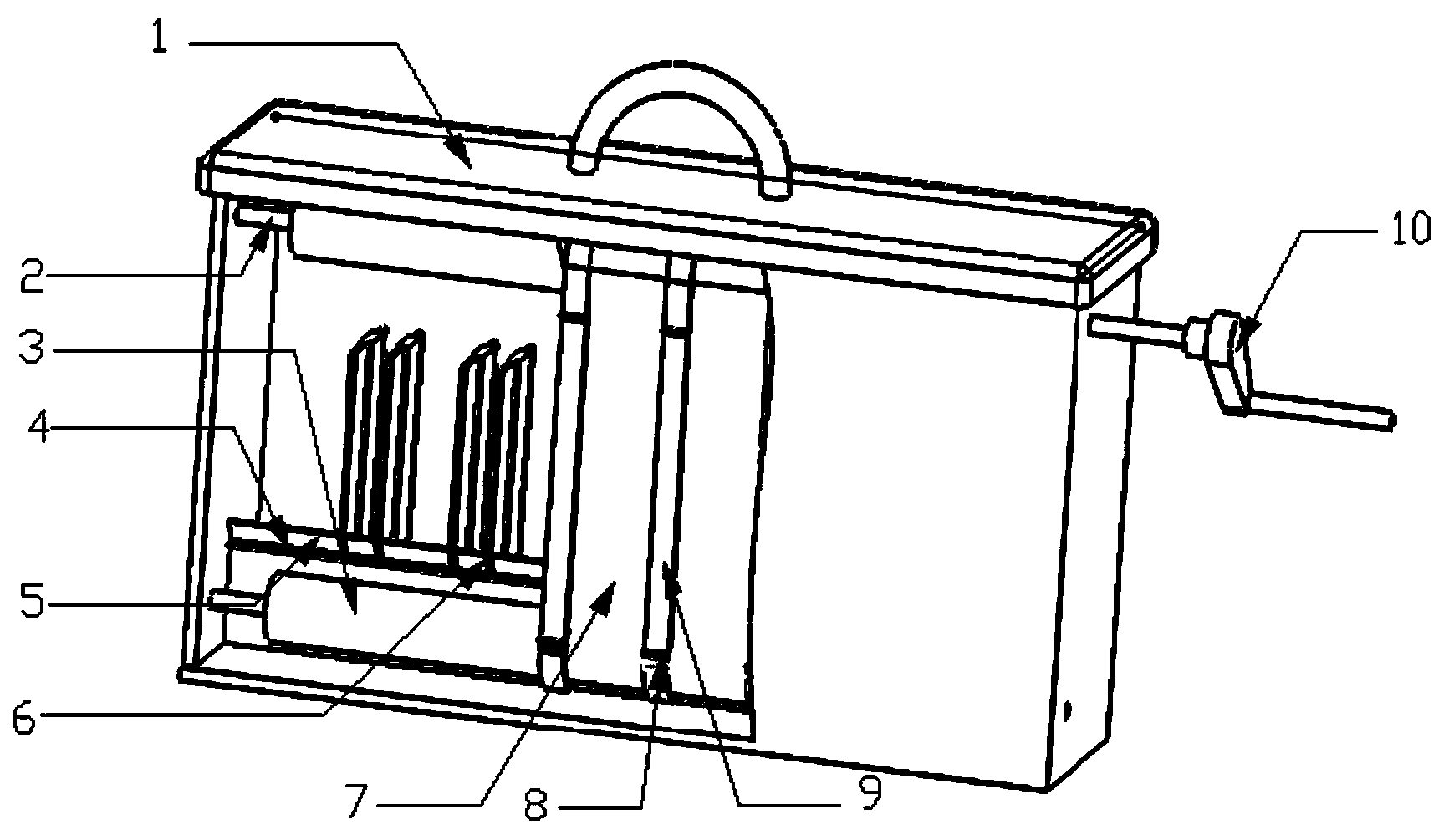

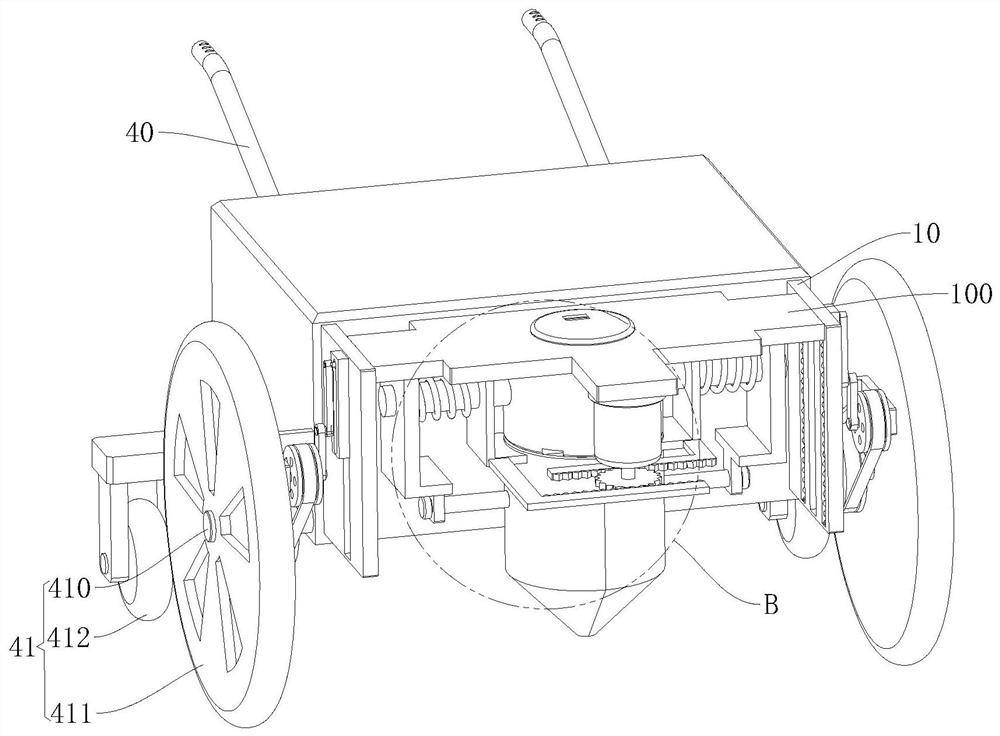

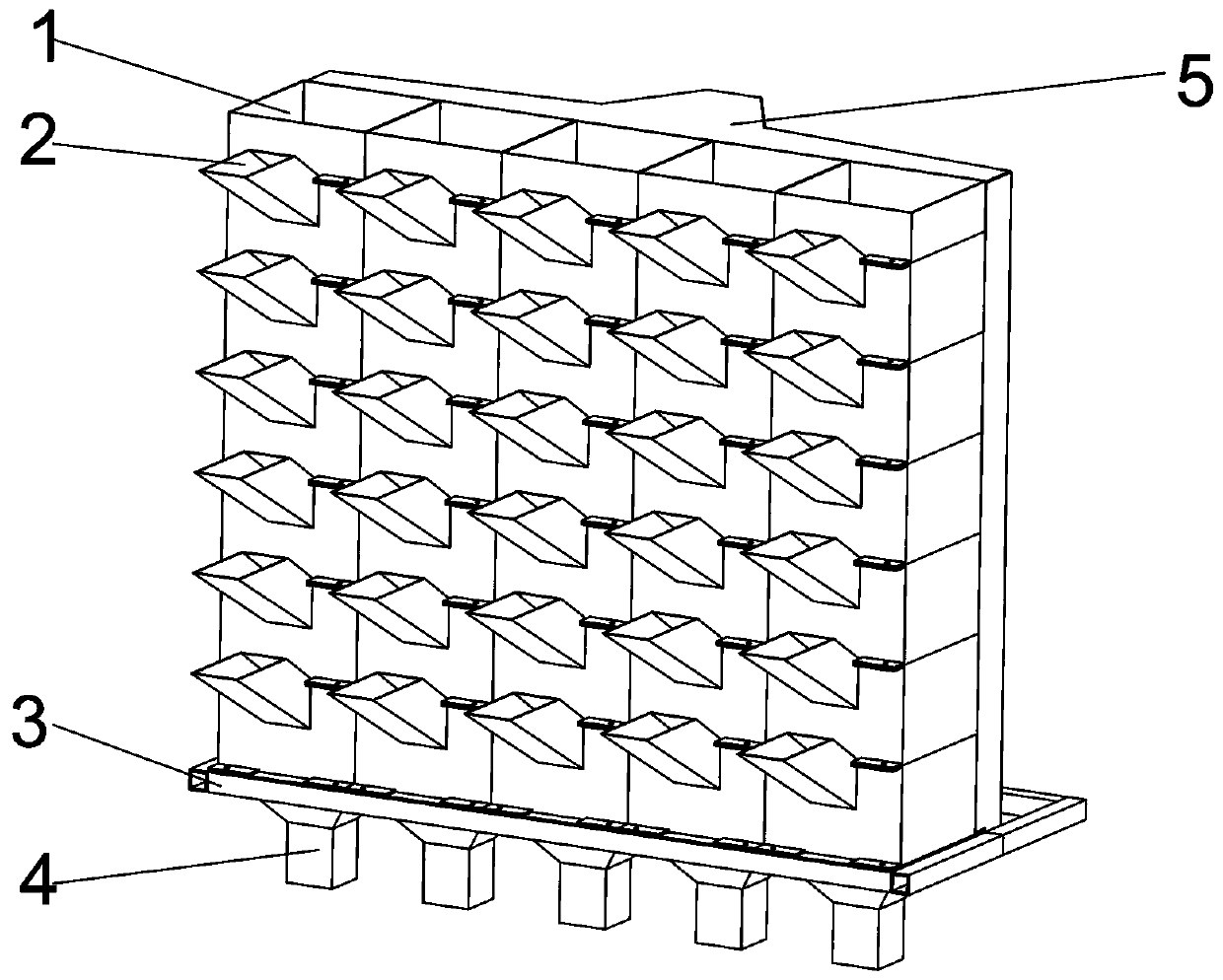

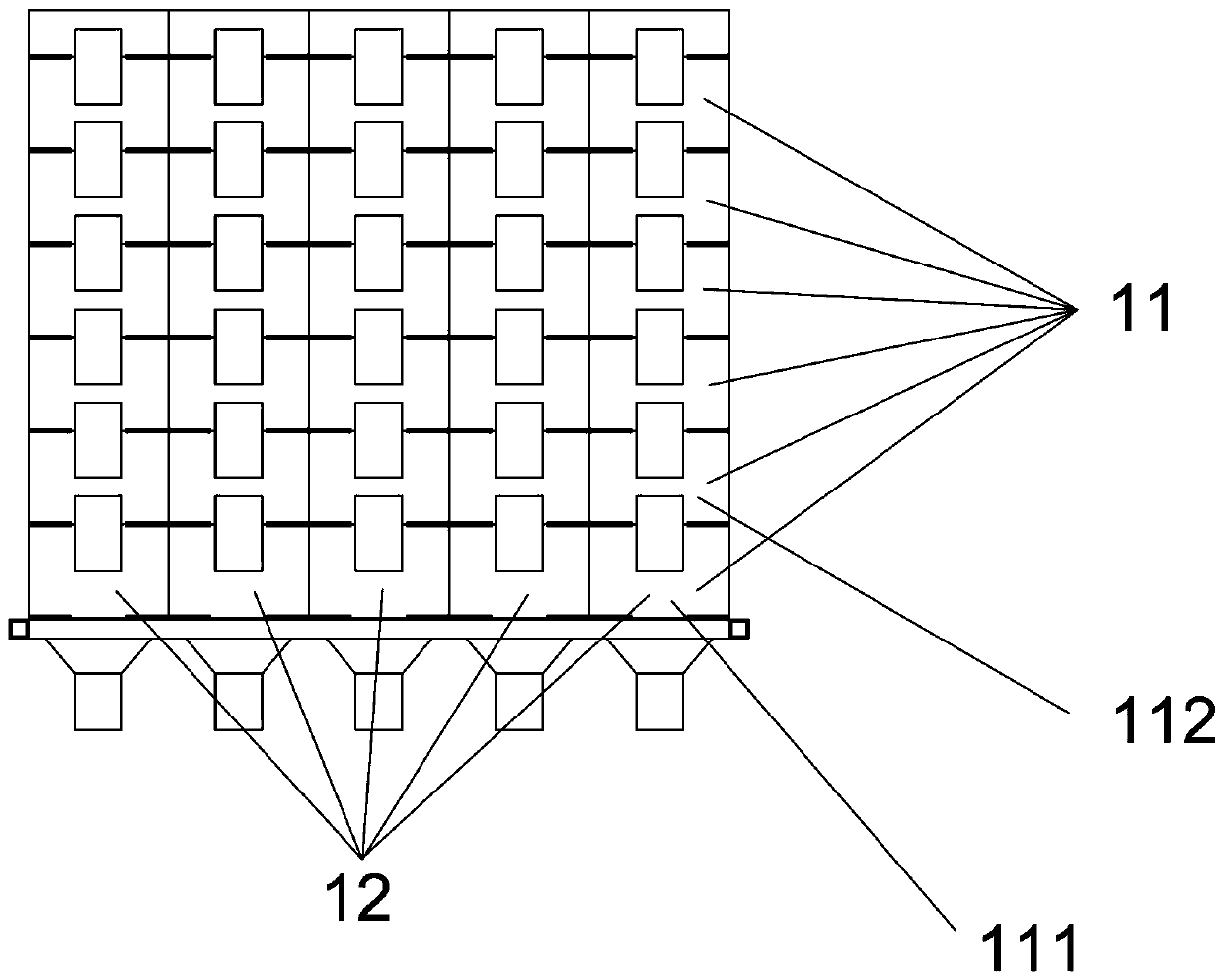

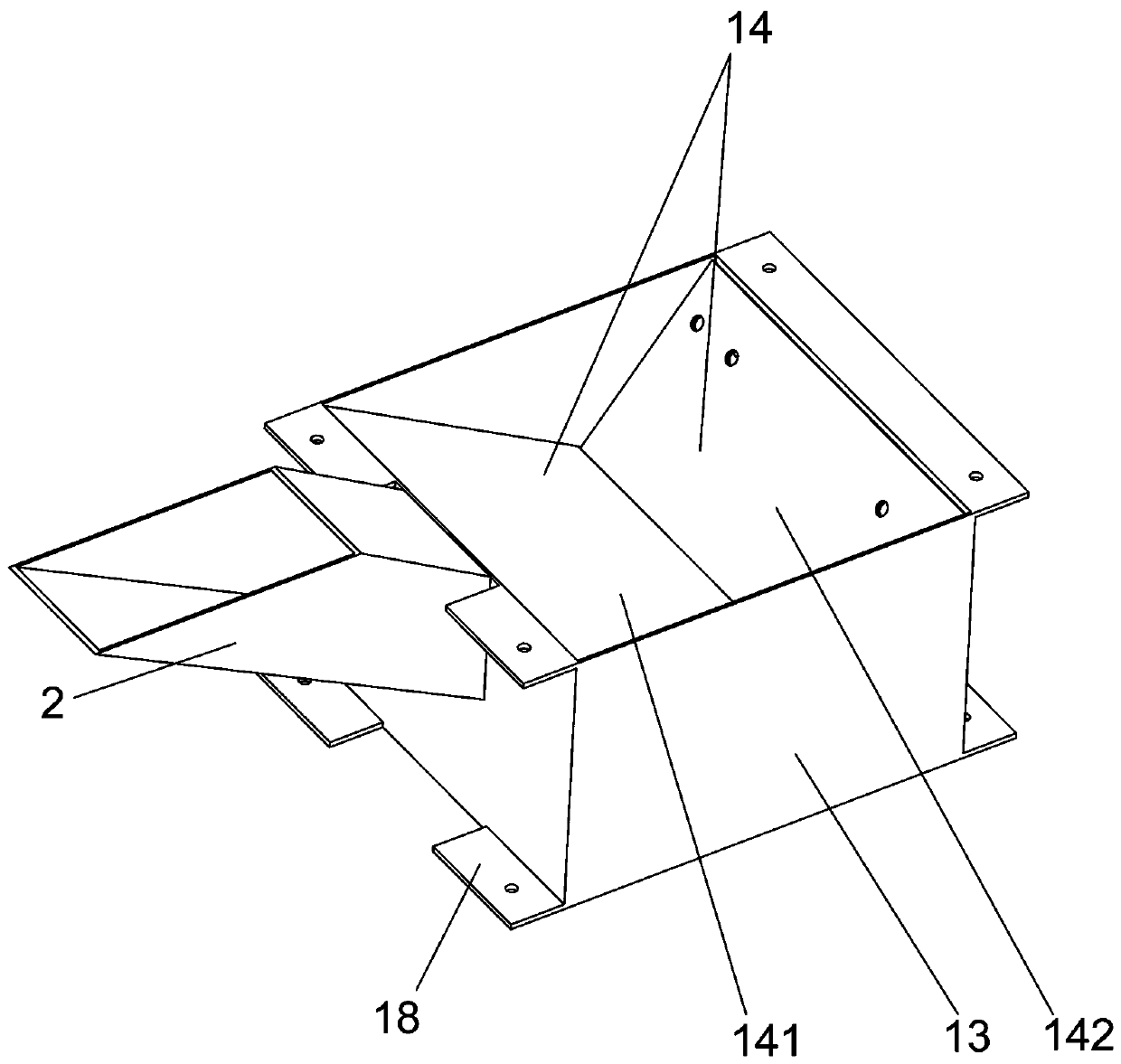

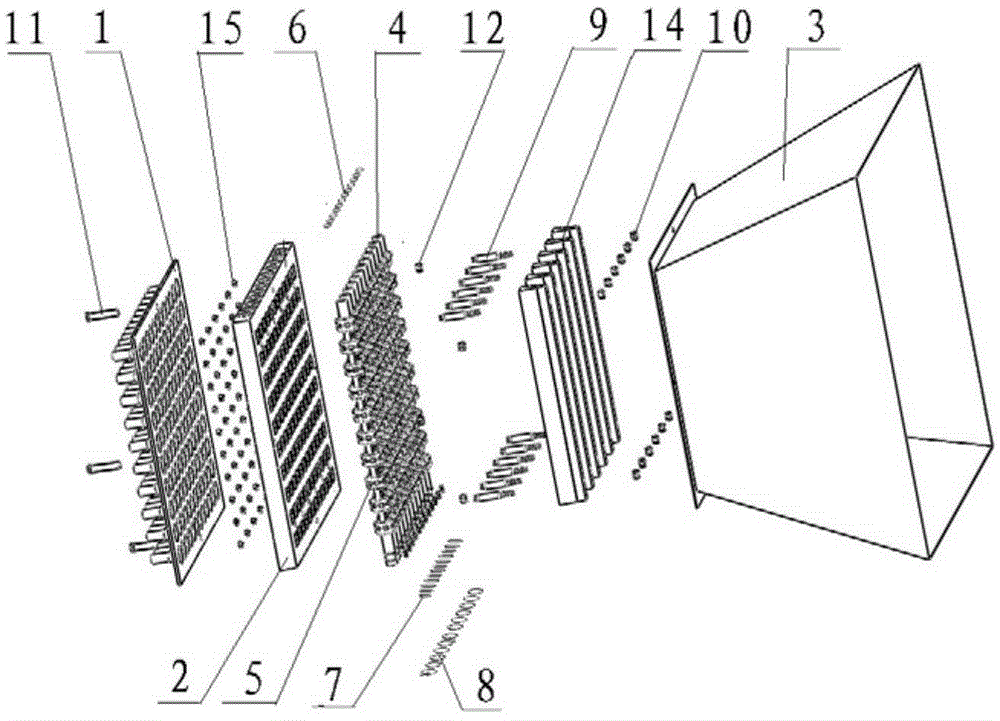

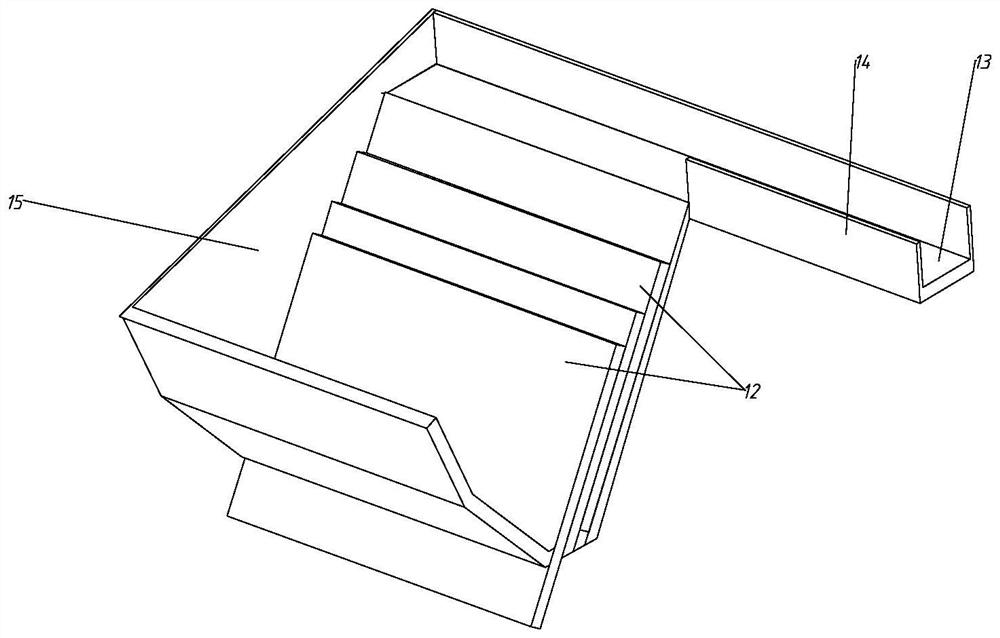

Combined automatic seed supply device of large-grain-size plot seeder

ActiveCN111083971AReduce in quantityImprove work efficiencySeed depositing seeder partsSeederAgricultural science

The present invention discloses a combined automatic seed supply device of a large-grain-size plot seeder. The combined automatic seed supply device of the large-grain-size plot seeder comprises a mounting rack, a seed storage unit and a control unit, the seed storage unit comprises seed box units and feeding units, and the feeding units are arranged on the seed box units; the multiple seed box units are vertically connected in series from bottom to top, also communicate to form vertical box groups, and are parallel in a transverse direction and mutually independent to form transverse box groups, and V-shaped combined material falling plates are arranged at material falling ports of the seed box units. The control unit is used to drive the vertical box groups to discharge seeds outwards insequence from bottom to top. The combined automatic seed supply device of the large-grain-size plot seeder is convenient to use, can realize automatic seed supply, can also automatically change seedsaccording to actual needs, and thus solves problems that manual seed supply is slow and common seed supply devices need to be stopped for manual seed change.

Owner:河南省农业科学院长垣分院

Mixed-sowing method suitable for high yield herbage in Qinghai-Tibet Plateau area

InactiveCN107409725AImprove qualitySolve the problem of insufficient grass productionPlant cultivationCultivating equipmentsMedium termWood pasture

The invention provides a mixed-sowing method suitable for high yield herbage in the Qinghai-Tibet Plateau area. The method includes the steps of sowing at the beginning of a growing season, clearing debris on the ground before sowing, and turning up the soil; plowing the field, wherein the depth is 15 cm; firstly, sowing broad beans, covering 2 cm of soil, secondly, sowing oats, and leveling the field, wherein the proportion of sowing numbers of the broad beans and the oats is 40:1; at the medium term of the growing season, reaping the oats before heading, and harvesting the parts above the field. By using the method, the herbage is mixed for sowing, the yield of the herbage can be improved, and the quality of the herbage can be improved.

Owner:LANZHOU UNIVERSITY

A kind of agricultural seeding equipment

ActiveCN112772058BReduce labor intensitySame shadePlantingDibble seedersAgricultural scienceAgricultural engineering

The invention relates to the field of agricultural machinery, in particular to an agricultural seeding device, which includes a body, a controller, a sowing mechanism, a traveling mechanism and a soil expansion mechanism. The mechanism includes a push handle and a rolling assembly. The soil expansion mechanism is located at the bottom of the spreading mechanism for digging holes. The soil expansion mechanism includes a drive assembly, two conical excavating shovels, two lateral sliding assemblies and two longitudinal sliding assemblies. , the sowing mechanism is arranged on the outer wall of the vehicle body for sowing seeds, the sowing mechanism includes a feeding component and an induction component, and the driving component and the induction component are electrically connected to the controller. The present invention relates to an agricultural The seeding equipment, instead of labor, has high seeding efficiency, can achieve quantitative seeding, avoid waste, and has less labor intensity.

Owner:芜湖星之原工业设计有限公司

A method of picking tomato seeds

ActiveCN107306537BQuality improvementImprove quality (germination rateSeed and root treatmentHarvestersFermentationHorticulture

The invention relates to a method for extracting tomato seeds. The method comprises the following steps: carrying out short-time fast fermentation on an extracted tomato juice seed mixture with pulp and seeds under a seed extracting condition by adopting a mode of adding fermentation mother liquid, wherein the seed extracting condition comprise preparation of the fermentation mother liquid: after fermenting the tomato juice seed mixture with pulp and seeds, which is extracted in the first step, under the normal temperature for 18 to 20 hours, filtering by using a gauze, taking supernatant as the fermentation mother liquid, and preserving fresh supernatant which is fermented and filtered in the same day as next fermentation mother liquid every time; extracting the seeds and fermenting; after completely fermenting, cleanly washing by pouring into gauze cloth or carrying out rinsing and separating by putting into a centrifugal tomato seed separator, and then airing on the gauze or airing in a cool and dry place. According to the method for extracting the tomato seeds, disclosed by the invention, the time span of tomato seed extraction during a seed sampling period can be remarkably shortened, seed germination during the seed sampling period can be effectively avoided, and the seed quality and the seed sampling efficiency are increased.

Owner:河北省农林科学院经济作物研究所

A high-efficiency precision positioning seeding method

ActiveCN105340434BEfficient and precise positioningImprove sowing qualitySeed depositing seeder partsRegular seed deposition machinesWave shapeEngineering

The invention relates to a high-efficiency accurate-measurement positioning seeding device and a method for seeding employing the same. The seeding device is composed of two structures A and B. The structure A can be placed in the structure B, and can move in the structure B. The middle part of the structure A is a seeding region. Seed holding tanks are arranged at two ends of the seeding region. One end of the structure A extends outwards and forms a handle. The cross section of the seeding region of the structure A is wave-shaped. A plurality of seeding holes are arranged at the wave-shaped valley bottoms. When a plate A is placed in the structure B, Seed passing holes are arranged in positions, corresponding to the seeding holes of the structure A, of the structure B. the seed passing holes correspond with the seeding holes one by one, and deviate towards one side by about half hole pitch relative to the seeding holes. The sizes of the seed passing holes are larger than that of the seeding holes. The provided seeding device is employed for seeding, high-efficiency accurate-measurement positioning can be achieved, the seeding quality and efficiency are raised, the seeding cost is lowered, convenience is provided for seedling growing production, and the provided seeding device is suitable for large-scale popularization.

Owner:YANGZHOU UNIV

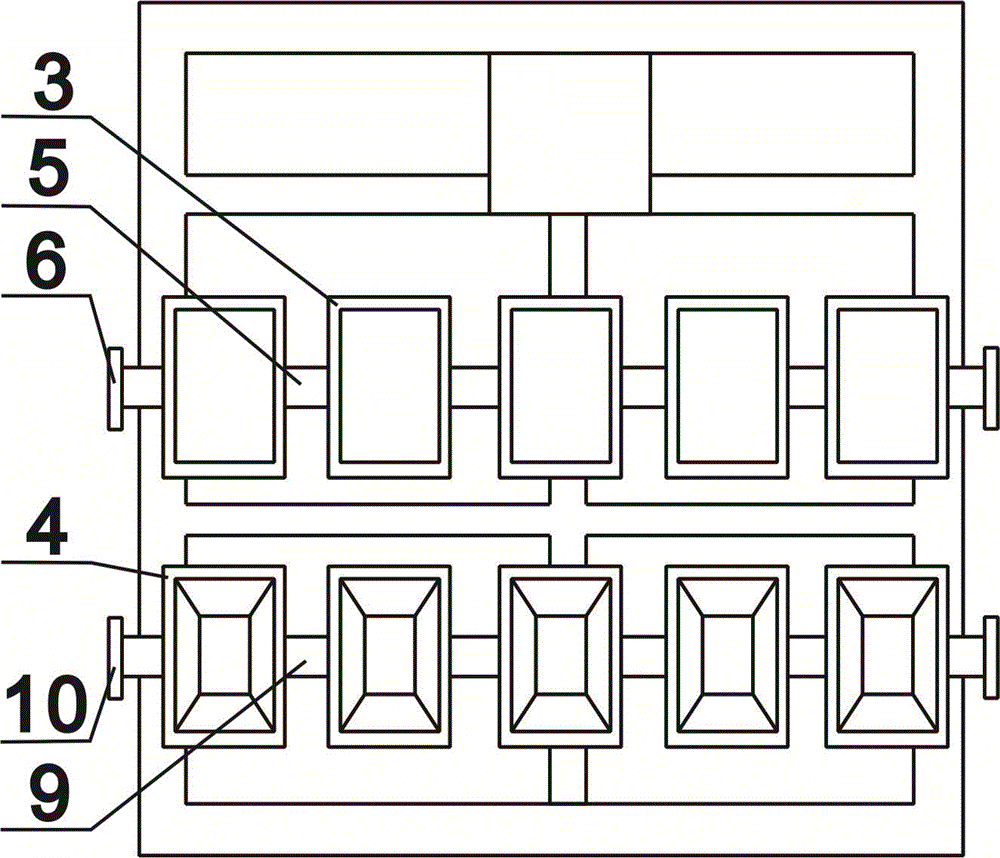

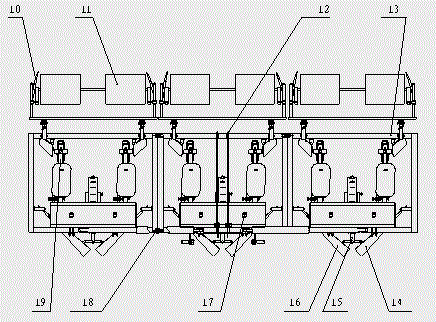

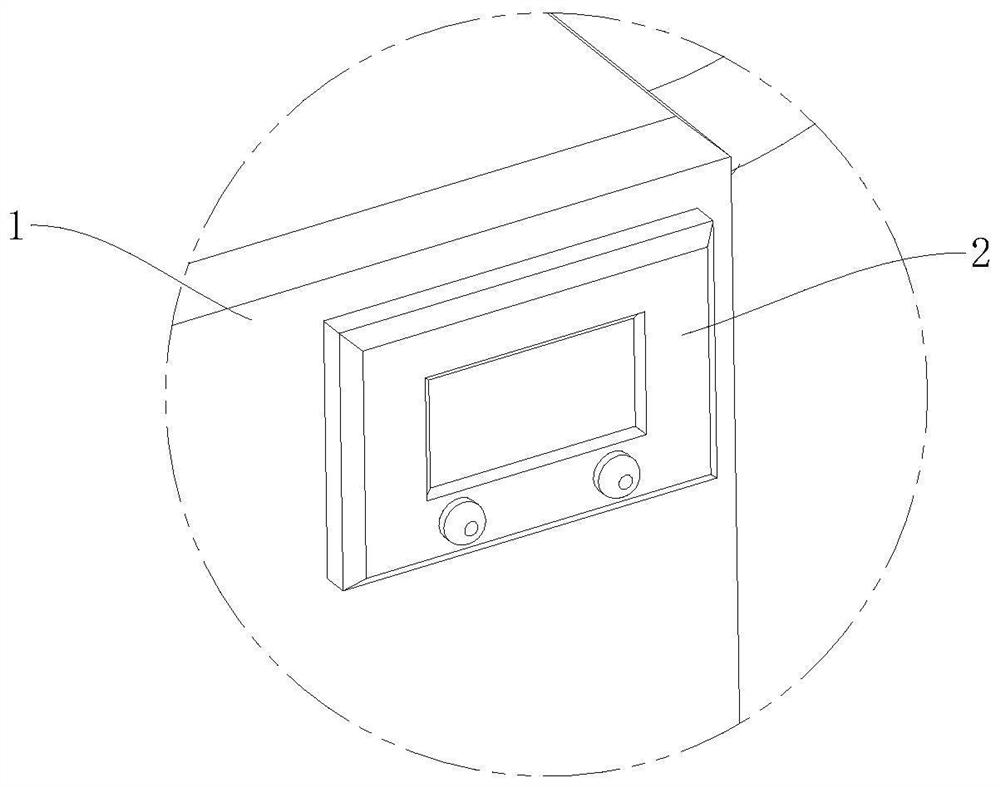

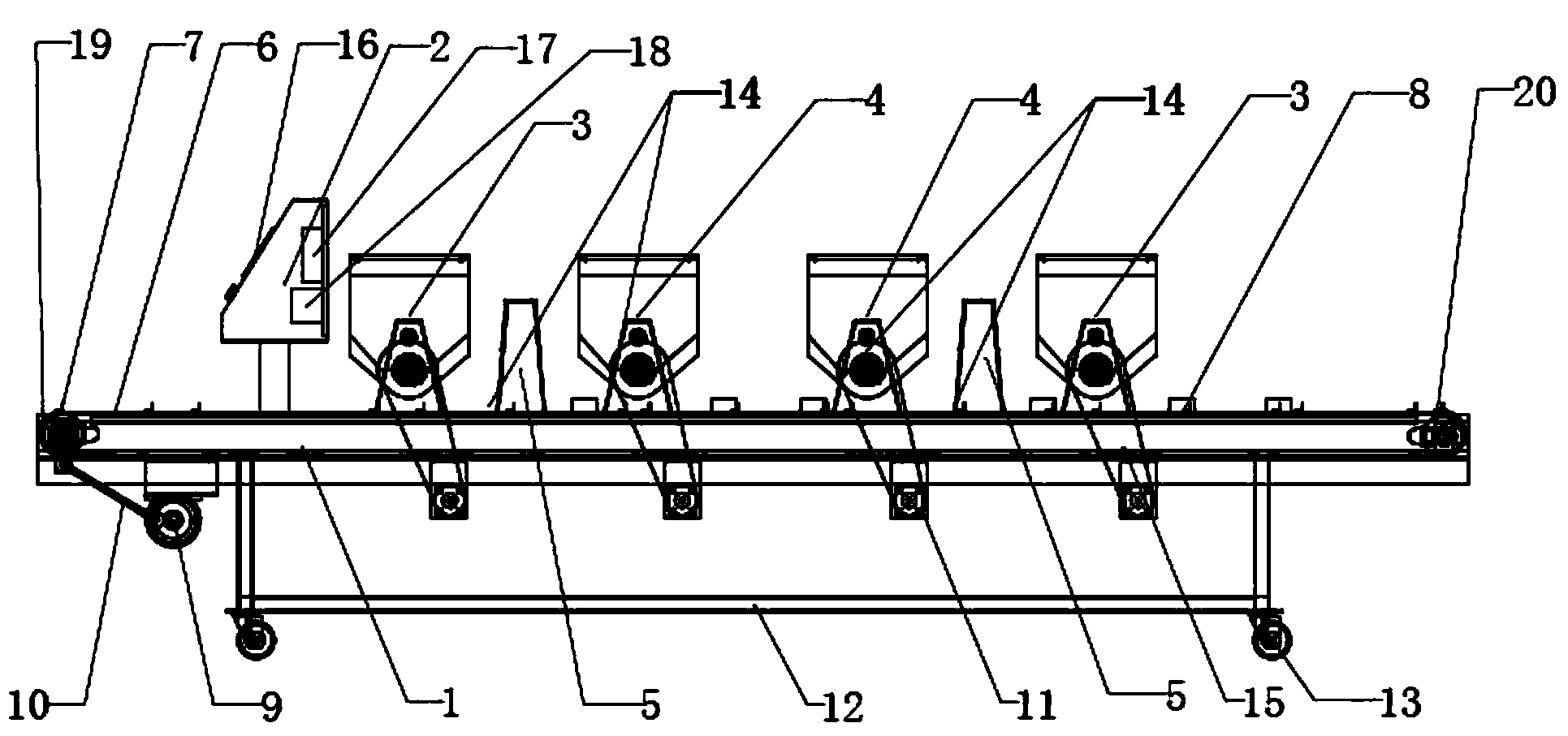

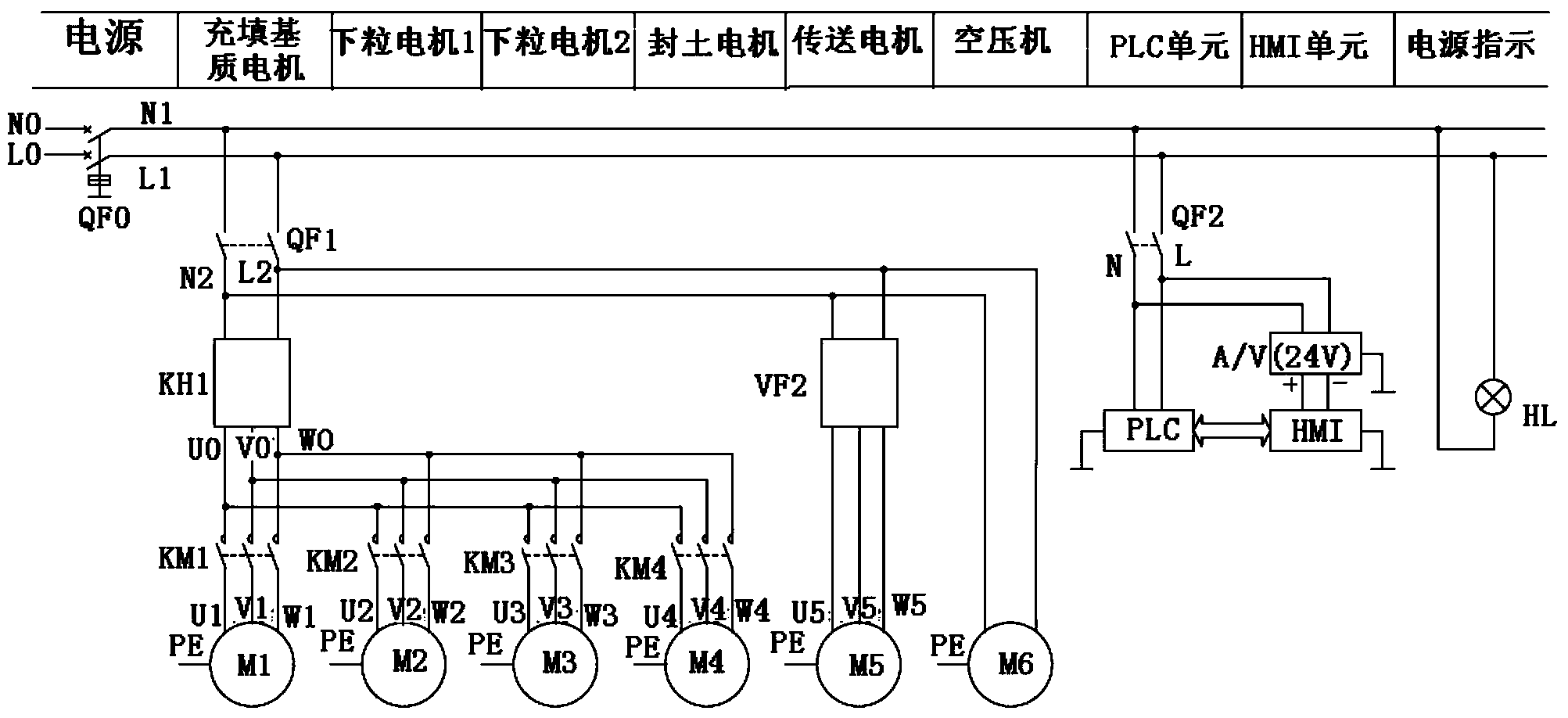

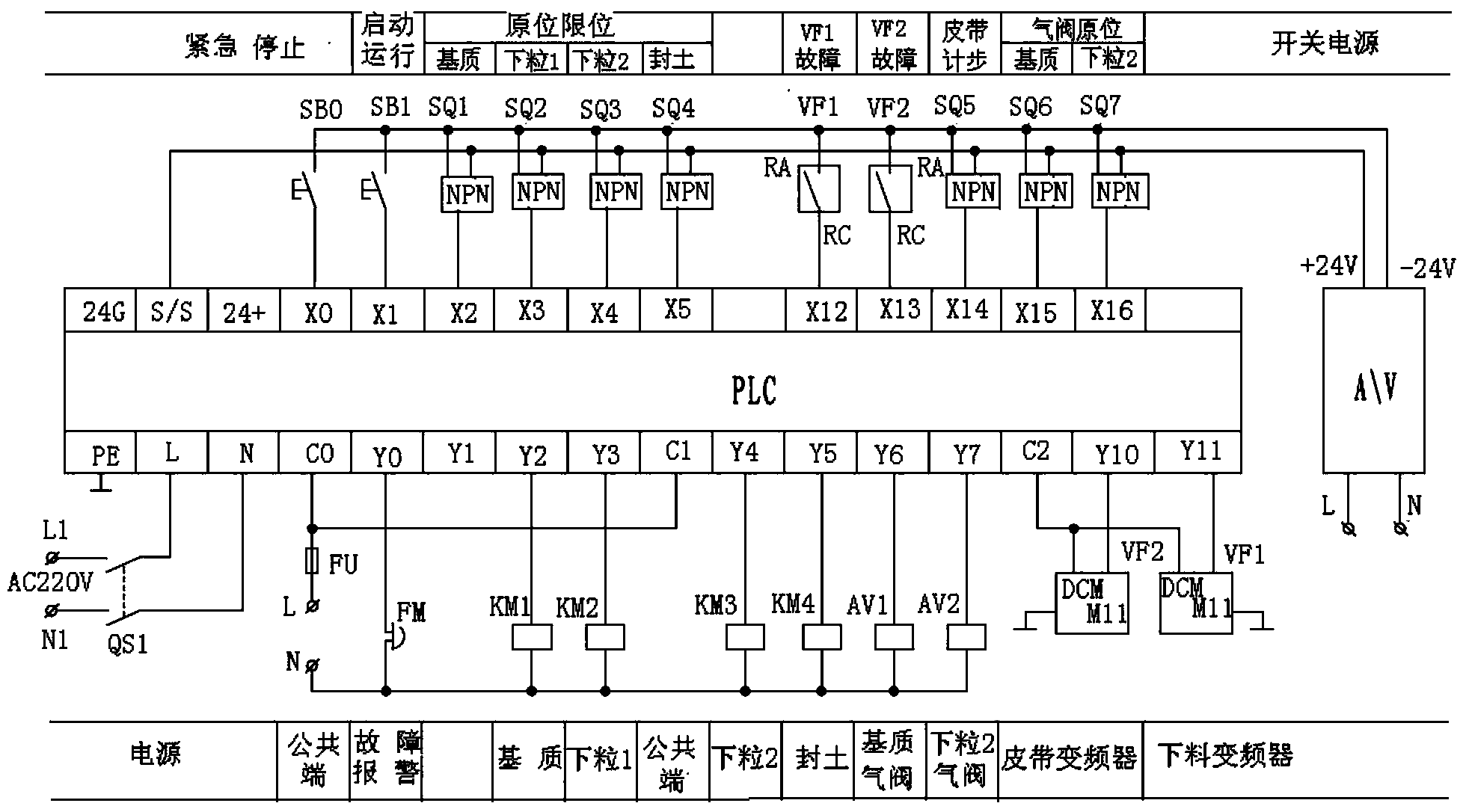

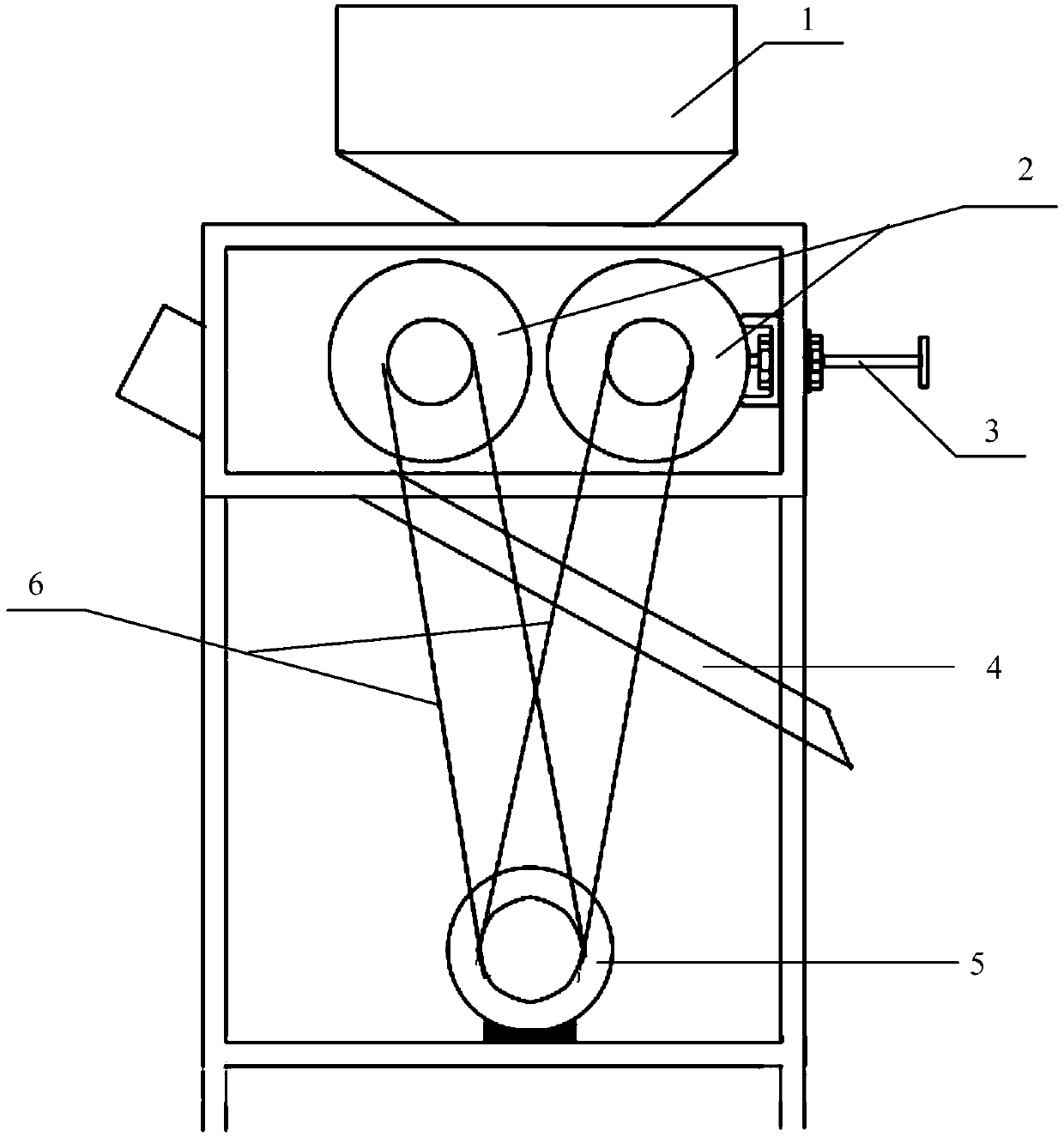

Seedling tray sowing device set

ActiveCN104238441ARealize joint operationGuaranteed no voidsProgramme control in sequence/logic controllersLiquid-crystal displayDevice Motor

The invention discloses a seedling tray sowing device set which comprises a machine frame, a conveying device, substrate filling devices, sowing devices, a hole pressing device, a pneumatic device and a control device. A supporting frame, a motor and a transmission guide rod are arranged below the machine frame. The two ends of the bottom of the supporting frame are respectively provided with a set of land wheels. The output end of the motor is connected with the transmission guide rod. A conveying belt and a seedling tray positioning assembly are installed above the machine frame. The seedling tray positioning assembly is placed on the conveying belt. The control device comprises an electronic control box, a liquid crystal display operation interface, an electrical apparatus element assembling plate, a programmable controller and a plurality of photoelectric sensors. The substrate filling devices, the sowing devices, the hole pressing device, the pneumatic device, the control device and the photoelectric sensors are installed on the machine frame. The two substrate filling devices and the two sowing devices are all connected with a protecting cover and a sowing device motor which is installed on the lower side of the machine frame. All the photoelectric sensors are connected with the electronic control box at one end of the machine frame. The programmable controller in the electronic control box is connected with all the devices. The seedling tray sowing device set has the advantages of being high in automation degree and suitable for seeds with different shapes.

Owner:NANYANG LIMIN TECH DEV

A method for using a water-retaining agent in drought-resistant sowing of peanuts, a sowing method and a system

ActiveCN105960882BSowing realizedPromote hydrationAgriculture tools and machinesLiquid seeding techniquesCrop cultivationAqueous solution

The invention discloses an application method of a water-retaining agent in peanut drought-resisting sowing, a sowing method and a system, and belongs to the technical field of crop cultivation. According to the method, a water-retaining agent water solution is pressed into peanuts with cracks in shells, then the shells of the peanuts are adhered with water-retaining agent powder, and then the treated peanuts are sown. According to the method, the utilization efficiency of the water-retaining agent is improved, the application amount of the water-retaining agent is reduced, and the water consumption demand for peanut seedling emergence and germination is ensured.

Owner:JIANGXI ACAD OF AGRI SCI

Double-layered growing method for lucern in mountainous areas of arid regions

InactiveCN102308720BIncrease success rateImprove effectivenessHorticultureAridOrthogonal test design

The invention relates to a double-layered growing method for lucern in mountainous areas of arid regions. The method is characterized in that: grandifoliate lucern is adopted as a main grown variety, an annual associated plant variety, such as rape, oat or highland barley, is chosen, and by means of a orthogonal test design and sowing order (position), growing spacing, growing depth, amount of applied fertilizer and other technical measures, and by utilizing the concealing and protectin effect generated by the double-layered growing method for the lucern in mountainous areas on lucern seedlings, the double-layered growing method can increase the current survival rate of the lucern seedlings. The double-layered growing method can promote the success of desert grassland improvement and artificial pasture construction under the environmental conditions of arid mountainous areas, becomes an optimal technology portfolio for growing lucern at medium and high altitudes in mountainous areas of arid regions, and greatly increases the survival rate of lucern in desert grassland restoration and artificial pasture construction and the yield of currently grown lucern in mountainous areas of arid regions at the altitude of 3000 to 1800 meters.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

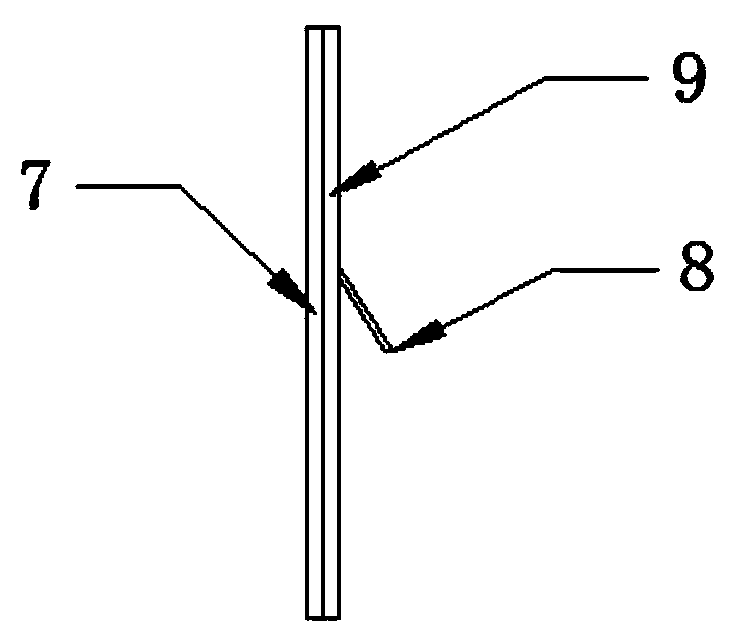

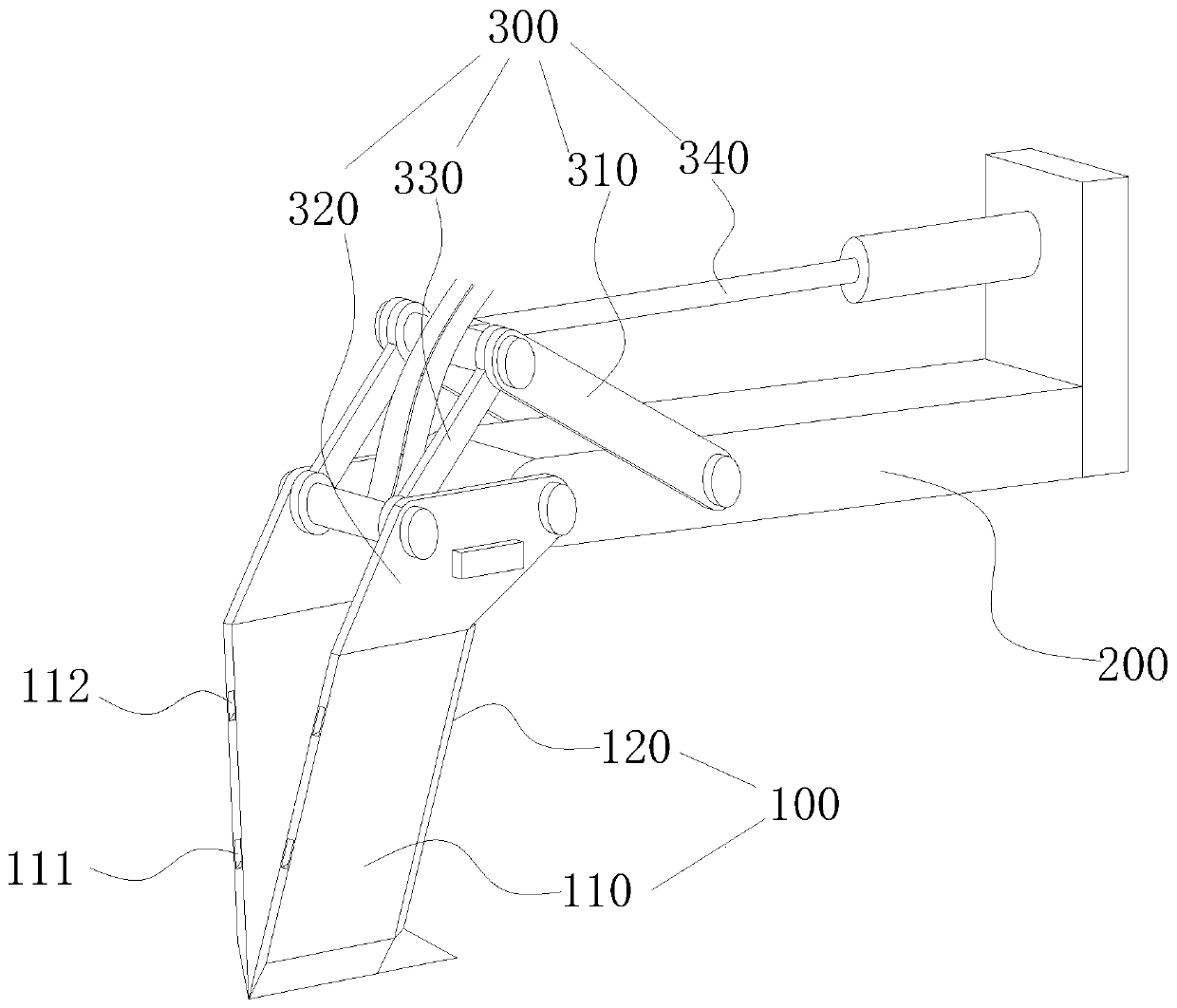

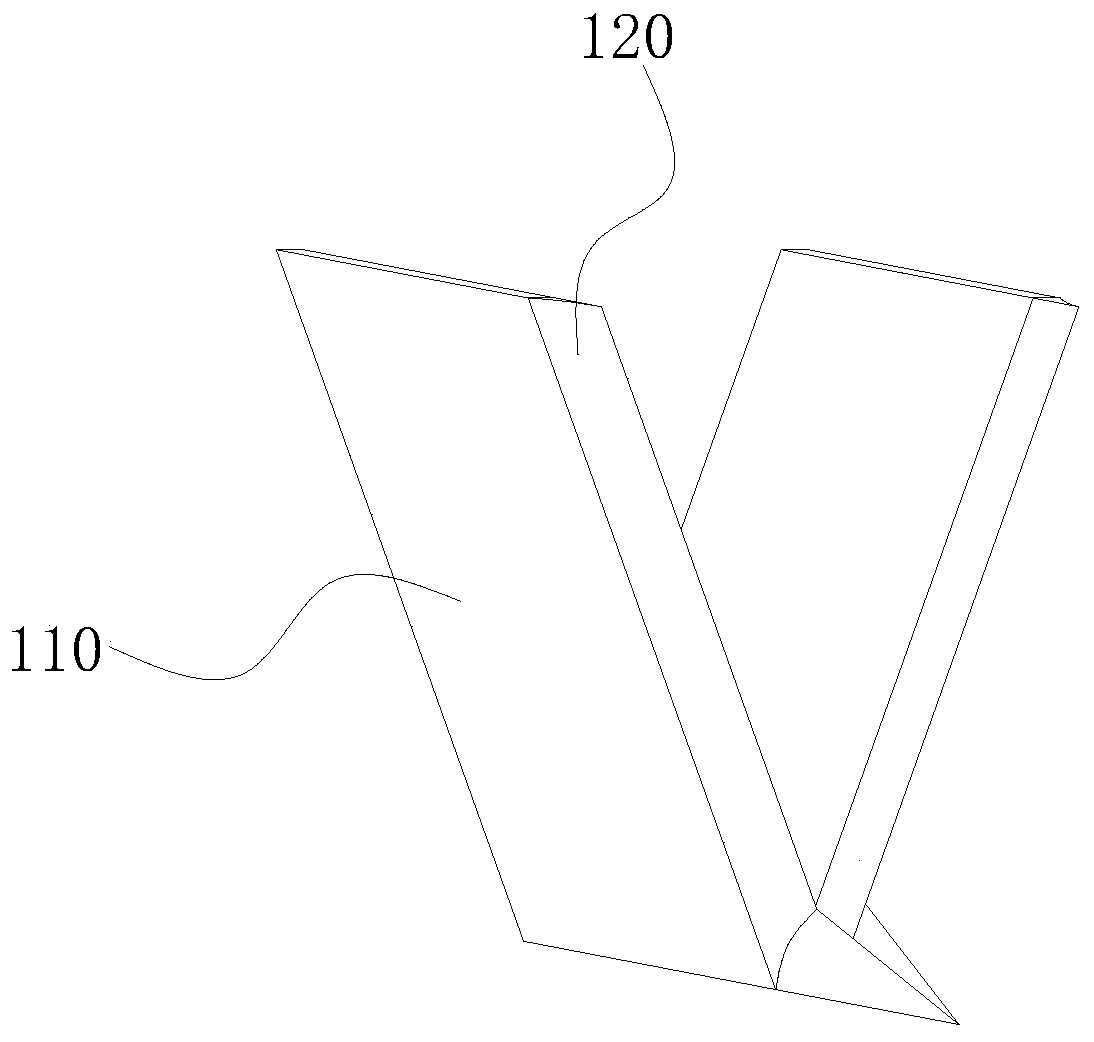

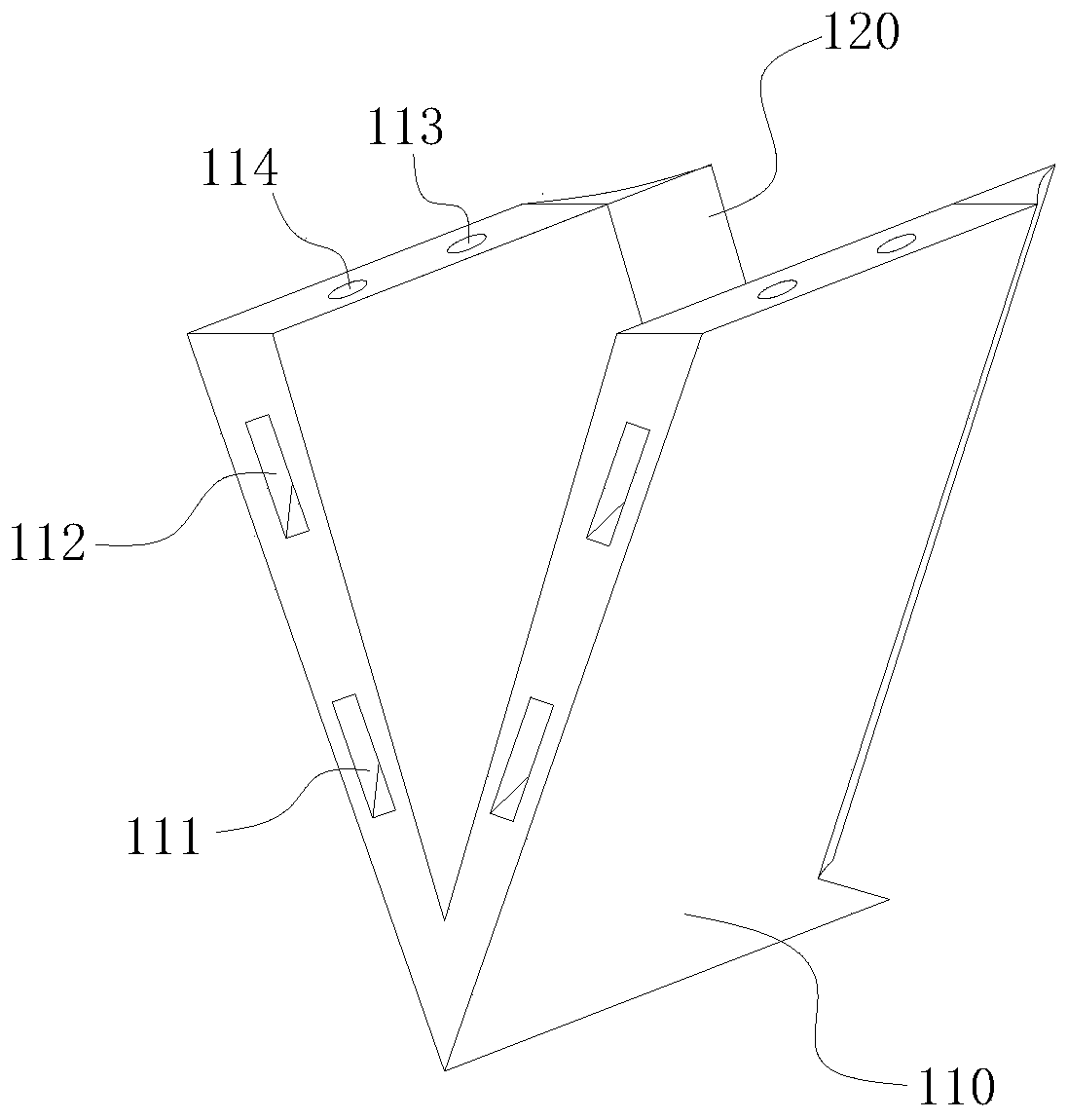

Minimum-tillage and non-tillage seeding head

PendingCN109874459ASimple processReduce seeding costsAgriculture gas emission reductionFertiliser and seeding apparatusMinimum tillageEngineering

The invention discloses a minimum-tillage and non-tillage seeding head. The seeding head comprises a frame body and a digging head rotationally fixed to the end of the frame body. The digging head comprises two seeding boards, the seeding boards are spliced into a whole in a V shape, an edge for cutting soil open is arranged at the side face of each seeding board at the soil facing side of the digging head, an air flue outlet for seeding and fertilizer applying is formed in the side face of each seeding board at the soil back side of the digging head, and a seeding channel communicated with aseed outlet is arranged inside the seeding boards. Accordingly, when no ditch needs to be formed, seeds are sown to the preset depth, the needed base fertilizer can be synchronously spread and appliedto the transverse and longitudinal positions of the seeds by a certain distance, the seeding working procedures are greatly simplified, and the seeding cost is lowered.

Owner:ANHUI AGRICULTURAL UNIVERSITY

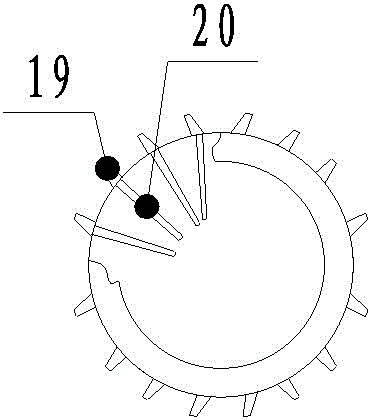

A Combined Hole Wheel Type Tray Seeder

InactiveCN103548453BImprove reliabilityReduce seeding costsSeed depositing seeder partsSingle grain seedersSeederAgricultural engineering

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

Composite Chinese yam rotary tillage seeder

The invention relates to the technical field of agricultural machinery, and provides a combined type Chinese yam rotary tillage seeder which comprises a rack and a seed discharging mechanism, the seed discharging mechanism comprises a seed discharging box, at least two chain wheels, a chain, a bearing and a plurality of seed protection corners, the seed discharging box is arranged on the rack and provided with an inlet and an outlet, the chain wheels and the bearing are rotationally arranged in the seed discharging box, and the chain is arranged on the seed protection corners. The chain is sleeved on the chain wheel and the bearing to form a triangular shape, the seed protection corners are arranged on the chain, and a seed metering space is formed between every two adjacent seed protection corners. Through the technical scheme, the problem of non-uniform Chinese yam seeding in the prior art is solved.

Owner:HEBEI NONGHAHA MASCH GRP CO LTD

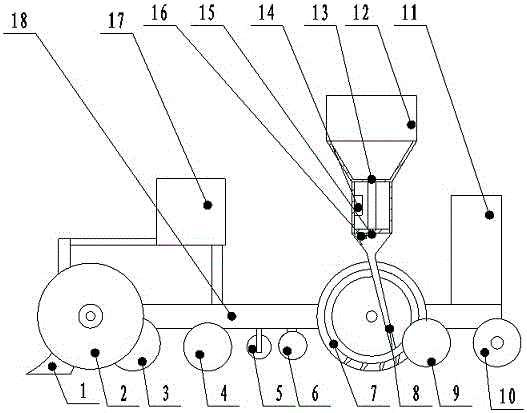

A thinning-free film side millet drill

InactiveCN104396388BReduce dosageReduce seeding costsSeed depositing seeder partsBroadcast seedersAgricultural engineeringEngineering

A membrane-side millet drill seeder being free of thinning belongs to agricultural machinery and is composed of a tractor, a plough, a travelling wheel, a membrane hanging roller, a soil hooking disk, a membrane unfolding roller, a membrane pressing roller, a millet seeding disk, a millet transporting pipe, a soil covering disk, a repressing roller, a water tank, a millet hopper and a fertilizer hopper. The plough, the travelling wheel, the membrane hanging roller, the soil hooking disk, the membrane unfolding roller, the membrane pressing roller, the millet seeding disk, the millet transporting pipe, the soil covering disk, the repressing roller, the water tank, the millet hopper and the fertilizer hopper are all fixedly installed on a rack. The rack is connected to the tractor. A vibrating device is installed on the millet hopper. A material discharging plate and a millet granule counting controller are installed at a millet discharging position of the millet hopper. The material discharging plate is connected to the millet granule counting controller. The membrane-side millet drill seeder can achieve integration of millet membrane-covering planting and membrane-side quantitative drill seeding and especially can achieving quantitative seeding, can save seed usage amount and can reduce a seeding cost.

Owner:CROP SCI RES INST SHANXI ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com