A processing method for milling free-form surface with ball-end cutter

A processing method and surface processing technology, which can be used in general control systems, instruments, computer control, etc., and can solve problems such as global optimization of cutting width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is a detailed description of the technical solution of the present invention in conjunction with the accompanying drawings.

[0043] like Figure 1-8 shown.

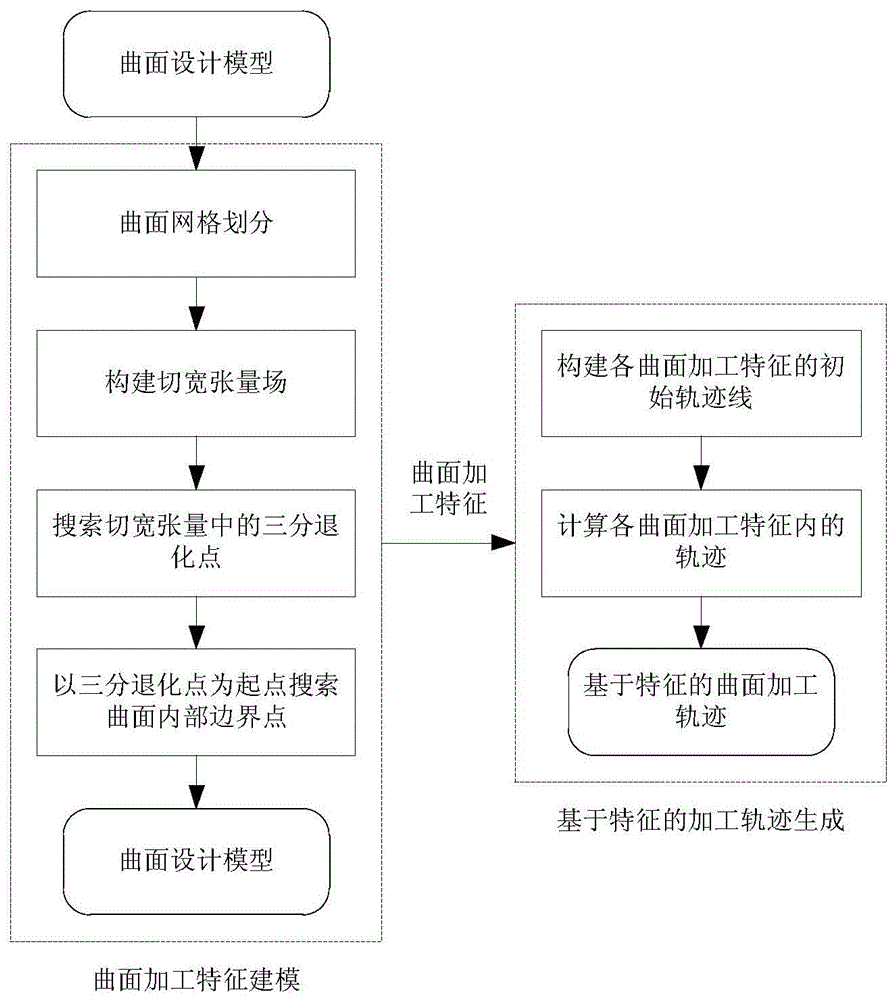

[0044] A processing method for milling a free-form surface with a ball-end cutter, such as figure 1 As shown, it mainly includes the following implementation steps:

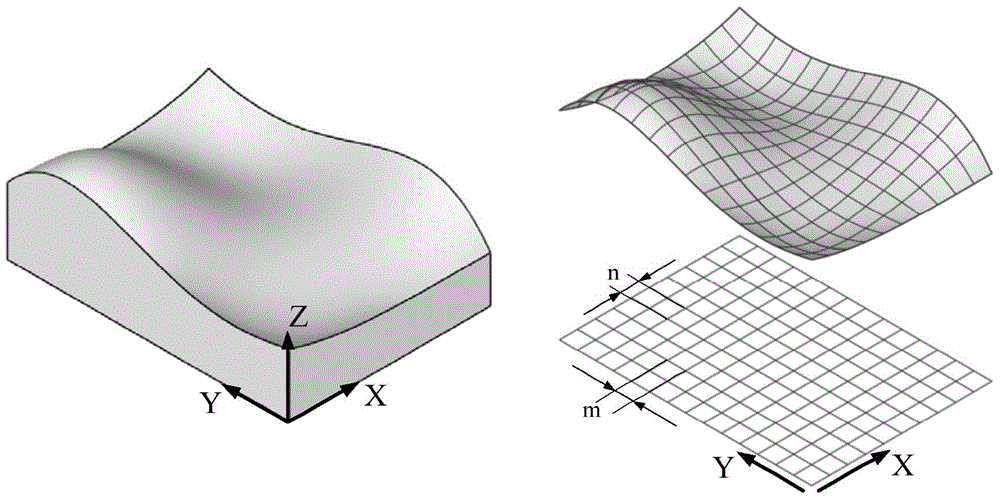

[0045] Step 1: Mesh the surface to obtain the list of grids contained in the surface and the grid points contained in each grid;

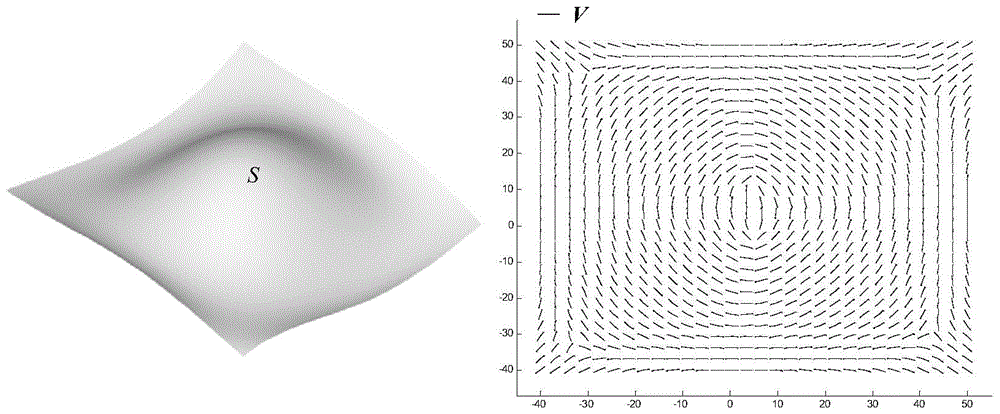

[0046] Step 2: Calculate the cut width tensor coefficient matrix at each grid point, and construct the cut width tensor field;

[0047] Step 3: Search for the degenerate points contained in the cut width tensor field, and extract the three-point degenerate points;

[0048] Step 4: Search for the internal boundary points of the surface with the three-point degenerate point as the starting point, construct the internal boundary of the surface, and obtain the processing characteristics of the surface.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com