ITO (indium tin oxide) transparent conductive film

A technology of transparent conductive film and transparent conductive layer, which is applied in the optical field, can solve the problems of obvious etching lines and difficult to completely eliminate etching lines of ITO transparent conductive film, and achieve the effect of eliminating obvious etching lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

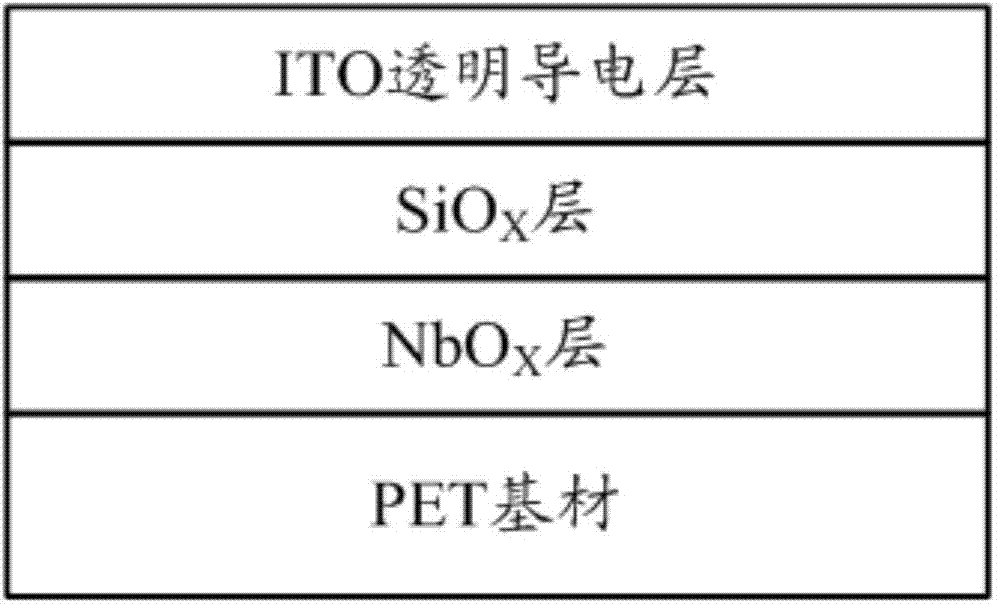

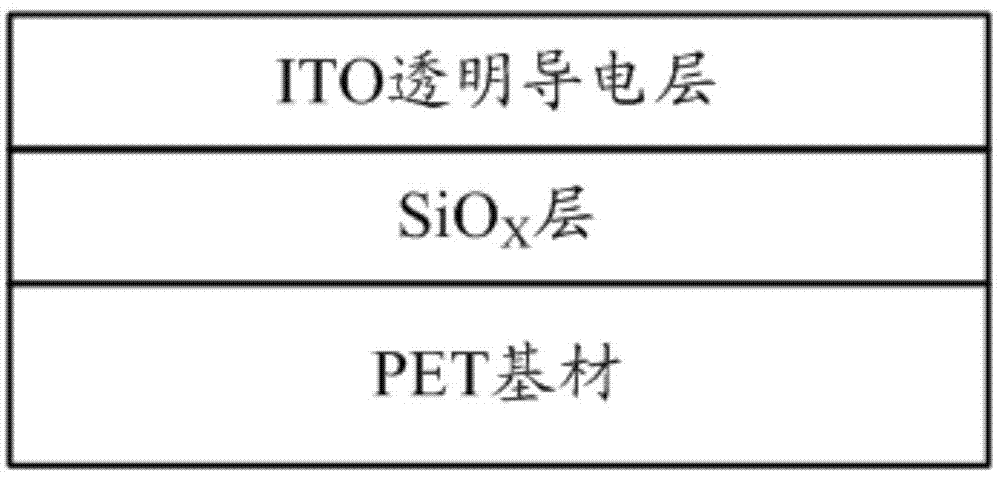

[0029] In the prior art, the production process of ITO transparent conductive film is as follows: a winding vacuum magnetron sputtering coating machine is used as the production equipment, a specific PET film is selected as the substrate, and the specific material is firstly sputtered through the design of the optical film system. A plurality of composite film layers are formed on the surface of the PET film, and then ITO is sputtered onto the material of the composite film layer to form an ITO transparent conductive film with conductive properties.

[0030] In the production process of transparent con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com