Motor rotor cooling structure

A technology for cooling structure and motor rotor, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problem of poor cooling effect of motor rotor, improve heat conduction efficiency, improve cooling effect, and reduce machining accuracy desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

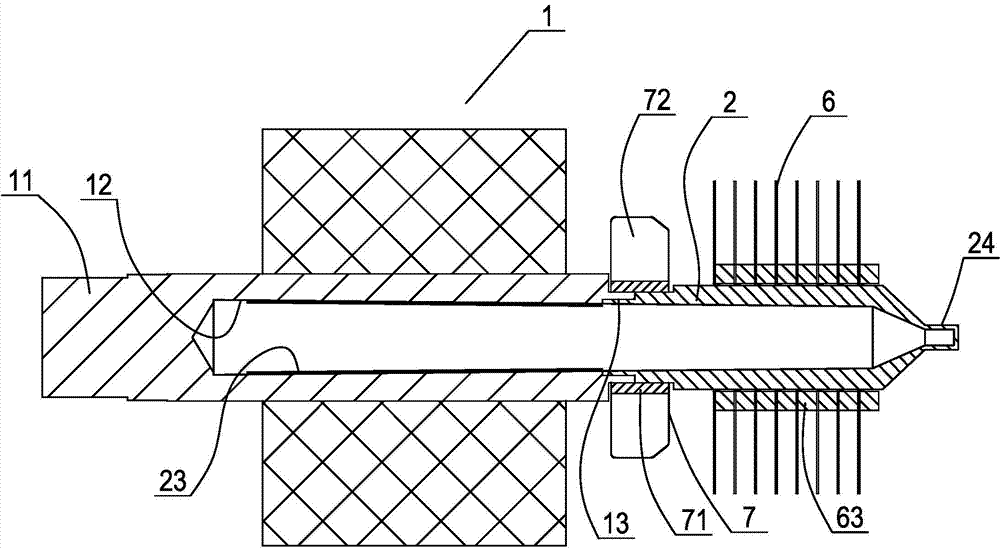

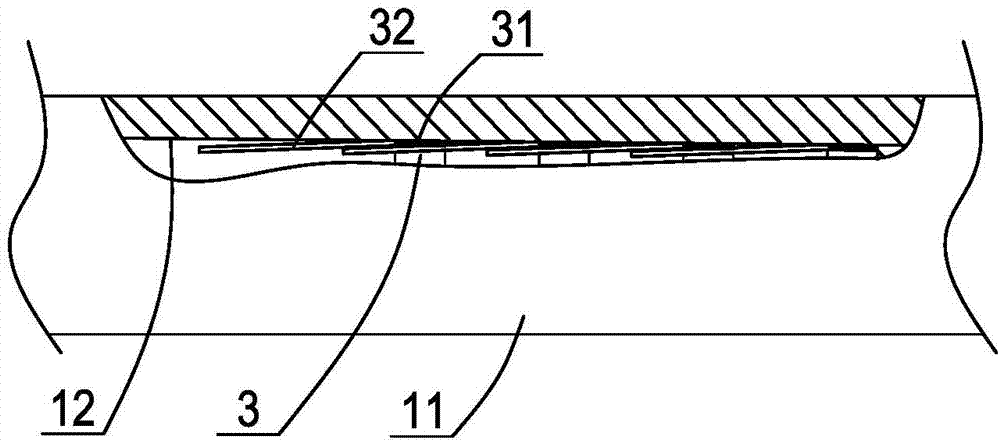

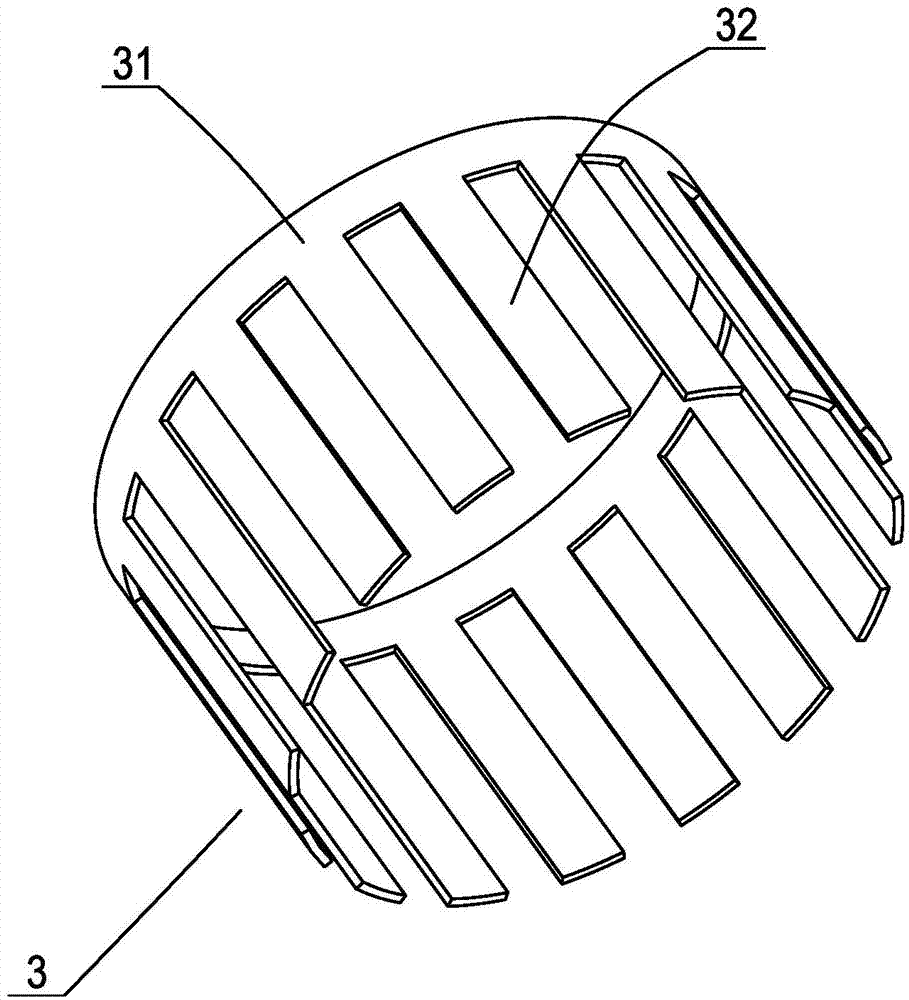

[0025] Such as figure 1 As shown, a motor rotor cooling structure is used to cool the motor rotor, including a rotor 1 and a heat pipe 2, and the motor shaft 11 used for output torque on the rotor is provided with a coaxial blind hole at one end in the motor housing 12. One end of the heat pipe is provided with a seal 24 for packaging, while the other end is open, and the open end of the heat pipe is fixedly connected to the open end of the blind hole. In this way, the motor shaft becomes an extension of the heat pipe, thus forming a spliced heat pipe. Of course, it is understandable that after fixing the heat pipe to the motor shaft, we need to pour the corresponding working medium into the heat pipe, and then use The seal seals the heat pipe. Since the heat pipe has a high heat transfer rate, the heat generated by the rotor during operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com