Step-type branched preformed end optical cable and production method thereof

A production method and optical cable technology, applied in the field of communication, can solve problems such as cumbersome operation, low work efficiency, waste of materials and labor costs, and achieve the effects of avoiding repeated construction, high production efficiency, and saving materials and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

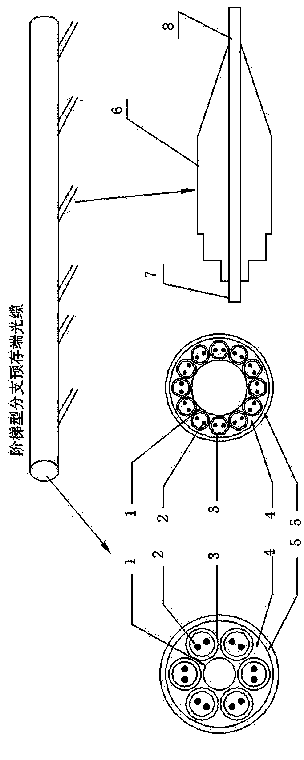

[0021] see figure 1 , a ladder-shaped pre-terminated optical cable and a production method thereof, the optical cable is sequentially provided with a central tensile body 1, an optical fiber 2, a microtube 3, an aramid fiber 4 and a flame-retardant sheath 5 from the inside to the outside, and the optical cable is also provided with Including a connector, the connector includes a connection body 6, a connection head 7 and a connection tail 8, and the connection body 6 is arranged in the middle of the connection head 7 and the connection tail 8; the height of the optical cable laying floor is N meters, where N is greater than 2, the position of the connector is set at N meters away from the head end of the optical cable, the second sub-cable is set at 2*N, the third sub-cable is set at 3*N, and the distance between the joints of each two sub-cables is Not less than N meters, and so on. When N is 4 meters, the height of the optical cable laying floor is 4 meters, the position of...

Embodiment 2

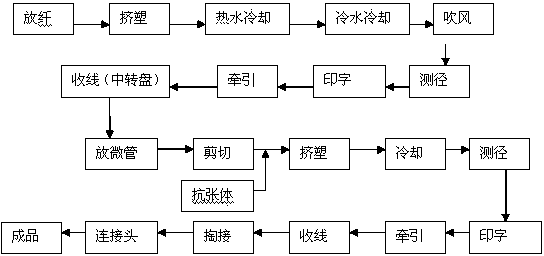

[0024] see figure 2 , image 3 , a method for manufacturing a ladder-type branch preformed end optical cable, the method is as follows:

[0025] 1) Unwinding, making microtubes, placing optical fibers of different colors on the pay-off rack; extruding, passing through the extruder, adding a layer of sheath to the optical fiber, and the appearance is round; cooling, passing through the water tank, and removing the sheath Cooling; blowing, passing through the blower to dry the surface of the optical cable without water marks; measuring diameter; printing, and then the inkjet printer sprays codes on the microtubes, which is easy to distinguish; traction, the traction machine gives power to the entire production line, Then directly on the market;

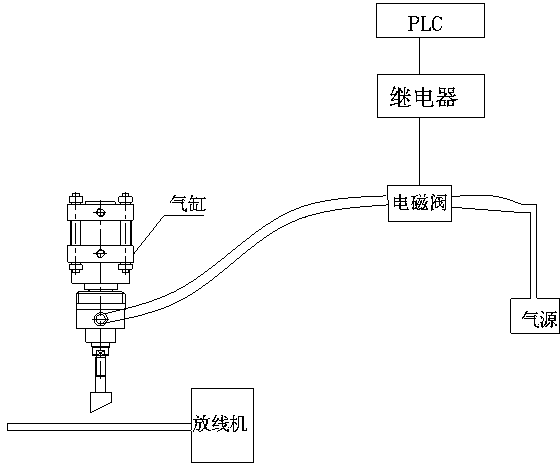

[0026] 2) Place the produced microtubes on the pay-off rack, and install an automatic cutting device in front of each pay-off rack. The length of the micro-tubes in this stepped branch optical cable is different, depending on the cus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com