Sliding friction generator, power generation method and vector displacement sensor

A displacement sensor and sliding friction technology, applied in the direction of triboelectric generators, using electric/magnetic devices to transmit sensing components, etc., can solve the problems of increased device manufacturing cost, easily damaged triboelectric materials, and complex structure of sliding friction generators, etc. Achieve the effect of prolonging the service life and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

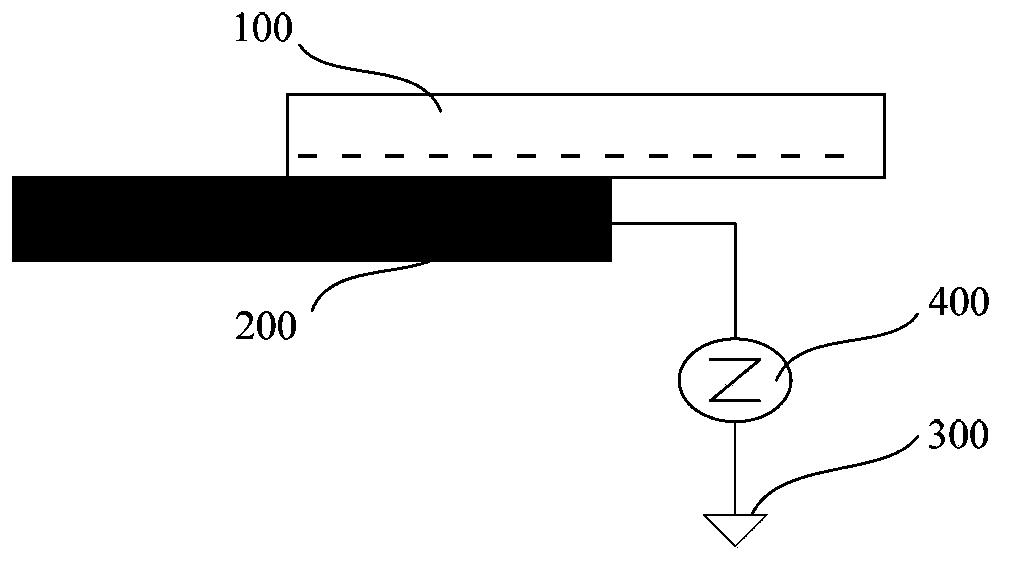

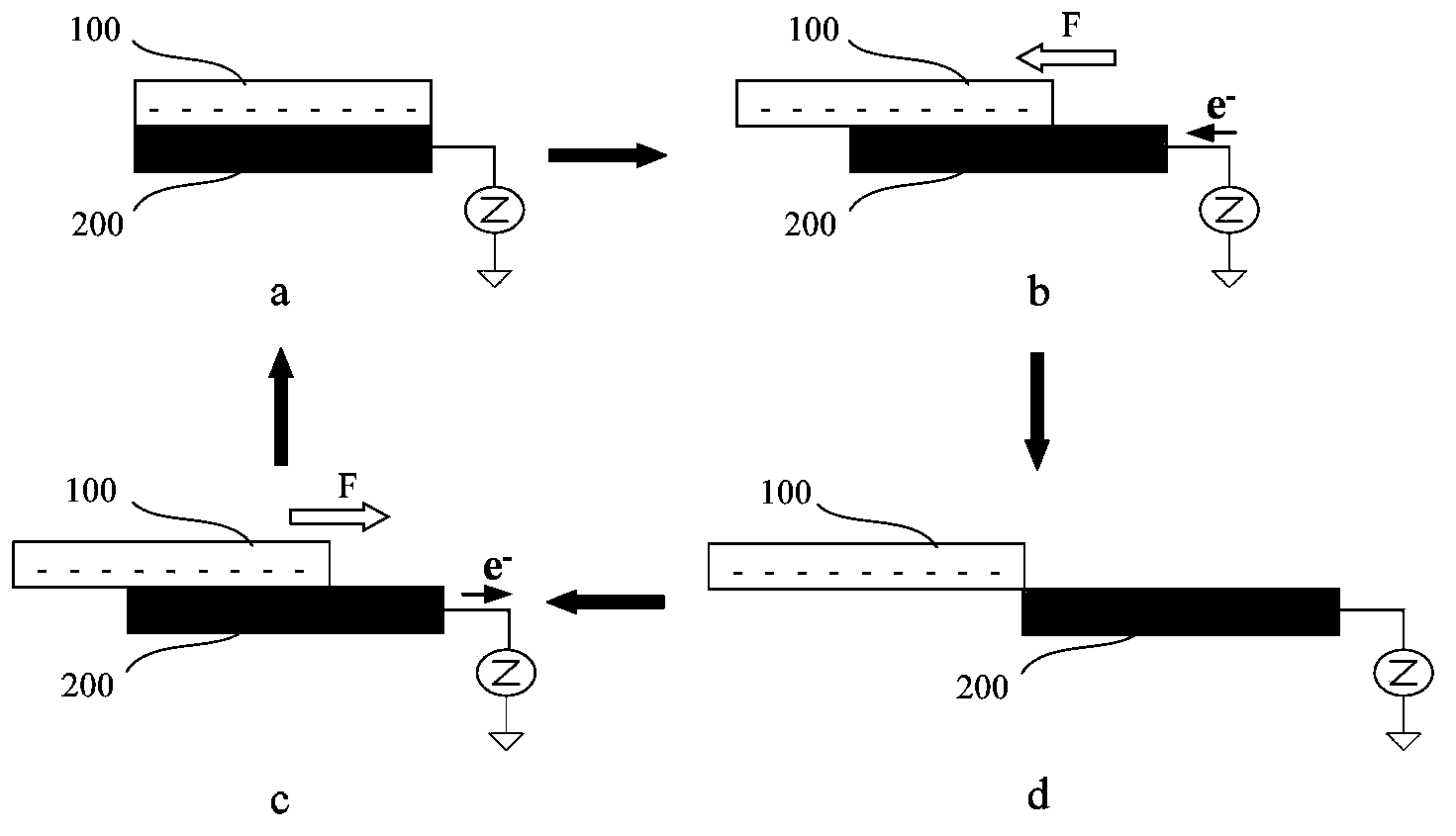

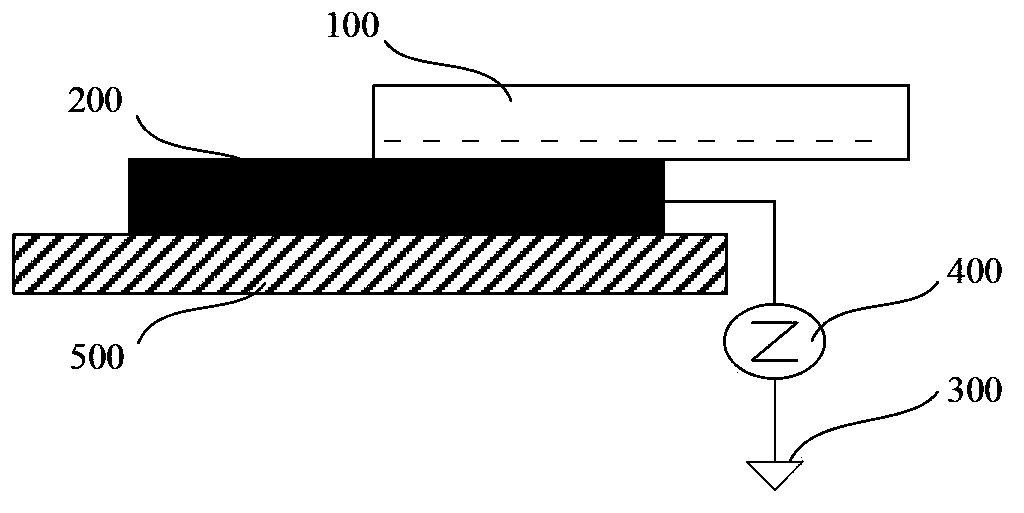

[0100] Example 1: Preparation of Sliding Friction Generator

[0101] Cut a polytetrafluoroethylene with a length of 10cm×width 5cm×thickness 1mm as the friction material layer of the device, and fix a piece of aluminum foil with a length of 10cm×width 5cm×thickness 25μm on a plexiglass material substrate of the same size with a copper wire Connect the Al foil and connect it to a resistor, and the other end of the resistor is grounded. Put the cut polytetrafluoroethylene on the surface of the aluminum foil. Under the action of external force, when the polytetrafluoroethylene and the aluminum foil slide relative to each other and the friction area changes, the voltmeter connected to the two ends of the resistor will have a corresponding electrical signal output, indicating that it can Convert the mechanical energy of external force into electrical energy for power generation.

Embodiment 2

[0102] Example 2: Preparation of vector displacement sensor based on sliding friction generator

[0103] A plexiglass with a length of 10 cm x a width of 10 cm x a thickness of 1.59 mm was cut by a laser as a substrate material of a sensor using a generator. Using the method of magnetron sputtering, 16 aluminum electrode strips were fabricated on the upper surface of the substrate as sub-electrodes, the width of the sub-electrodes was 10mm, and the length was 3cm. The distance between the electrode strips is 2 mm. The 16 sub-electrodes are distributed in four directions to form a cross structure in groups of 4. The 4 sub-electrodes in each group are arranged in parallel and equidistant, as shown in Figure 9 shown. Connect each aluminum electrode strip with a copper wire, and connect it to a voltage divider resistor R, the other end of the voltage divider resistor is grounded, and an output terminal 01...15, 16 is drawn between each electrode strip and the voltage divider res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com