A heat-sensitive electronic cigarette liquid and its preparation

An electronic cigarette liquid, heat-sensitive technology, applied in the direction of tobacco, tobacco processing, smoker's products, etc., can solve the problems of backflow, inconvenient storage and transportation, gap in atomization volume, back suction, etc., to achieve easy storage, prevent volatilization, and prevent leakage. liquid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

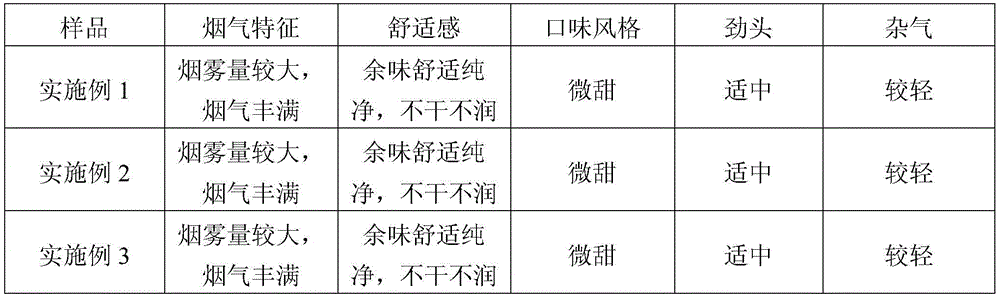

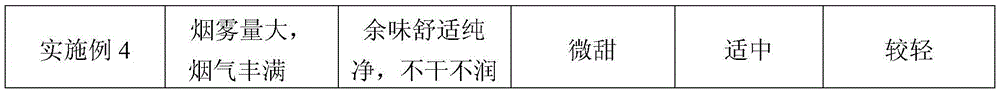

Examples

Embodiment 1

[0031] A heat-sensitive electronic cigarette liquid, comprising the following components in weight percent: 8% tobacco extract, 2% nicotine, 1% malic acid, 3% tobacco flavor, 6% gelatin, 32% water, 48% propylene glycol, each The sum of the components is 100 parts, and it is prepared after mixing.

[0032] The preparation method of the tobacco extract adopts a conventional method, and the specific process is as follows: the tobacco leaves are dried at 40° C., cooled to room temperature, and ground. Take 50g of tobacco powder and place it in a 500ml Erlenmeyer flask, add 250ml of deionized water, shake and extract at 65°C for 30min. A total of 3 extractions were performed, and the extracts were combined, concentrated to 25 ml by rotary evaporation under reduced pressure, and the tobacco extract was obtained.

[0033] The present invention has no special limitation on the type and source of the tobacco flavor, and the tobacco flavor well known to those skilled in the art can be ...

Embodiment 2

[0035] Same as Example 1, the difference is that it contains the following components in weight percentage: 5% tobacco extract, 2% nicotine, 1% malic acid, 3% tobacco essence, 2% available rubber, 30% water, 57% Propylene glycol, the sum of each component is 100 parts, prepared after mixing.

Embodiment 3

[0037] Same as Example 1, the difference is that the following components are included in percentage by weight: 8% tobacco extract, 2% nicotine, 1% malic acid, 3% tobacco essence, 1% agar, 25% water, 60% propylene glycol, mixed Made evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com