A high carbon and high chromium 9cr18 martensitic stainless steel shaft forging preparation process

A martensitic stainless steel and preparation process technology, applied in metal processing equipment and other directions, can solve the problems of reducing the plasticity, toughness and contact fatigue properties of steel, and achieve the effect of shortening solidification segregation and improving carbide segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

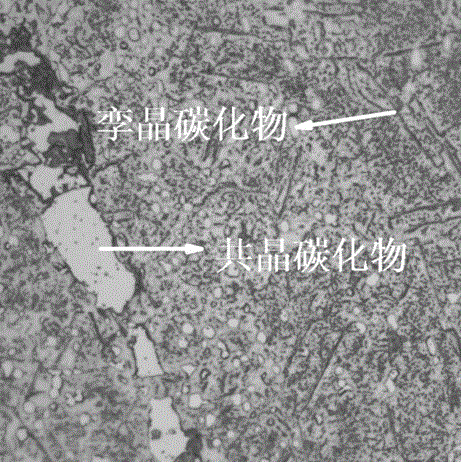

Image

Examples

Embodiment 1

[0020] A high carbon and high chromium 9Cr18 martensitic stainless steel shaft forging preparation process, the forging specification is φ430×6300, the process method is as follows:

[0021] Smelting: electric arc furnace smelting + vacuum refining + electroslag remelting, the main chemical composition is controlled as follows: C: 0.90~0.92, Cr: 17.0~17.5, Si: 0.50~0.55, Mn: 0.40~0.45; casting temperature is controlled at 1450 ~1480°C;

[0022] Forging: 10.5 tons of electroslag ingots are used for forging, and the electroslag ingots are hot-sent and heated. The heating temperature is 1140-1180°C, the initial forging temperature is 1000-1120°C, and the final forging temperature is 900-950°C. The equipment used is 5,000 tons Hydraulic press blanking and 1400-ton precision forging machine forming, the deformation method adopts upsetting and drawing length, the total forging ratio is 8.5-9.5, the upsetting coefficient is 2.0-3.0, and the deformation method is: use whole body light...

Embodiment 2

[0025] A high carbon and high chromium 9Cr18 martensitic stainless steel shaft forging preparation process, the forging specification is φ530×5300, the process method is as follows:

[0026] Smelting: electric arc furnace smelting + vacuum refining + electroslag remelting, the main chemical composition is controlled as follows: C: 0.90-0.92, Cr: 17.0-17.5, Si: 0.50-0.55, Mn: 0.40-0.45; casting temperature is controlled at 1450 ~1480°C;

[0027] Forging: 10.5 tons of electroslag ingots are used for forging, and the electroslag ingots are hot-sent and heated. The heating temperature is 1160±10°C, the initial forging temperature is 1000-1120°C, the final forging temperature is 900-950°C, and the equipment used is 5000 The billet is opened by a 1-ton hydraulic press and formed by a 1400-ton precision forging machine. The deformation method adopts upsetting and drawing, the total forging ratio is 8.5-9.5, and the upsetting coefficient is 2.5-3.5. Inverted octagonal - rounded, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com