Device and method for splitting randomly polarized laser light

A technology of random polarization and polarized light, applied in the field of laser, can solve the problems of power ratio limitation of splitting, inability to perform precise adjustment, poor consistency of processing quality, etc., to achieve high utilization rate of total power, improve energy control accuracy, and reduce energy decay. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

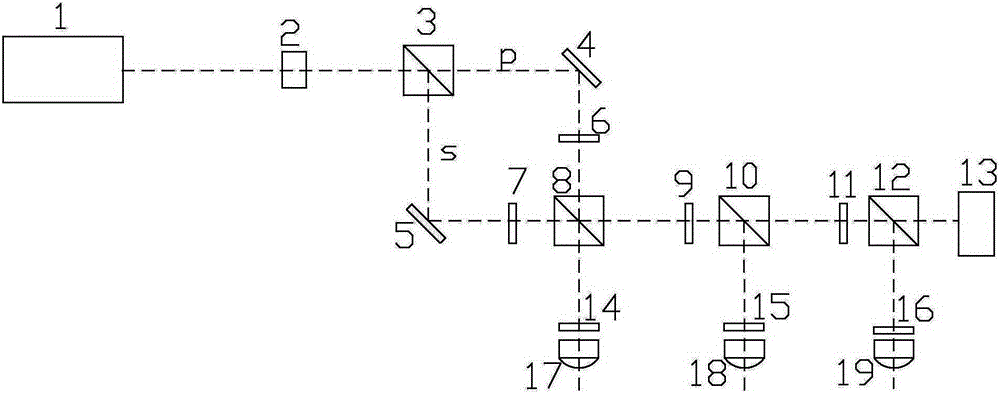

[0020] The invention utilizes a polarized stereoscopic beam splitter (PBS) to split the random polarization laser light and the power of each beam can be continuously adjusted.

[0021] Such as figure 1 As shown, in the device for splitting random polarized laser light, the optical path of the output end of the laser 1 is arranged in sequence with a shutter collimation unit 2 and a first polarizing stereoscopic beam splitter PBS3, and the beam transmission output end of the first polarizing stereoscopic beam splitter PBS3 is set The first total reflection mirror 4 is arranged, the light beam reflection output end of the first polarizing stereoscopic beam splitter PBS3 is provided with the second total reflection mirror 5, and the beam reflection output ends of the first total reflection mirror 4 and the second total reflection mirror 5 are provided with the first total reflection mirror 5. Two polarizing three-dimensional beam splitter PBS8, the optical path between the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com