Metal pyramid type lattice sandwich plate and preparation method thereof

A technology of pyramids and sandwich panels, applied in metal layered products, chemical instruments and methods, lamination devices, etc., can solve the problem of high production cost of metal lattice structures, many production defects of metal lattice structures, and low material utilization. and other problems, to achieve the effect of low cost, short preparation process and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

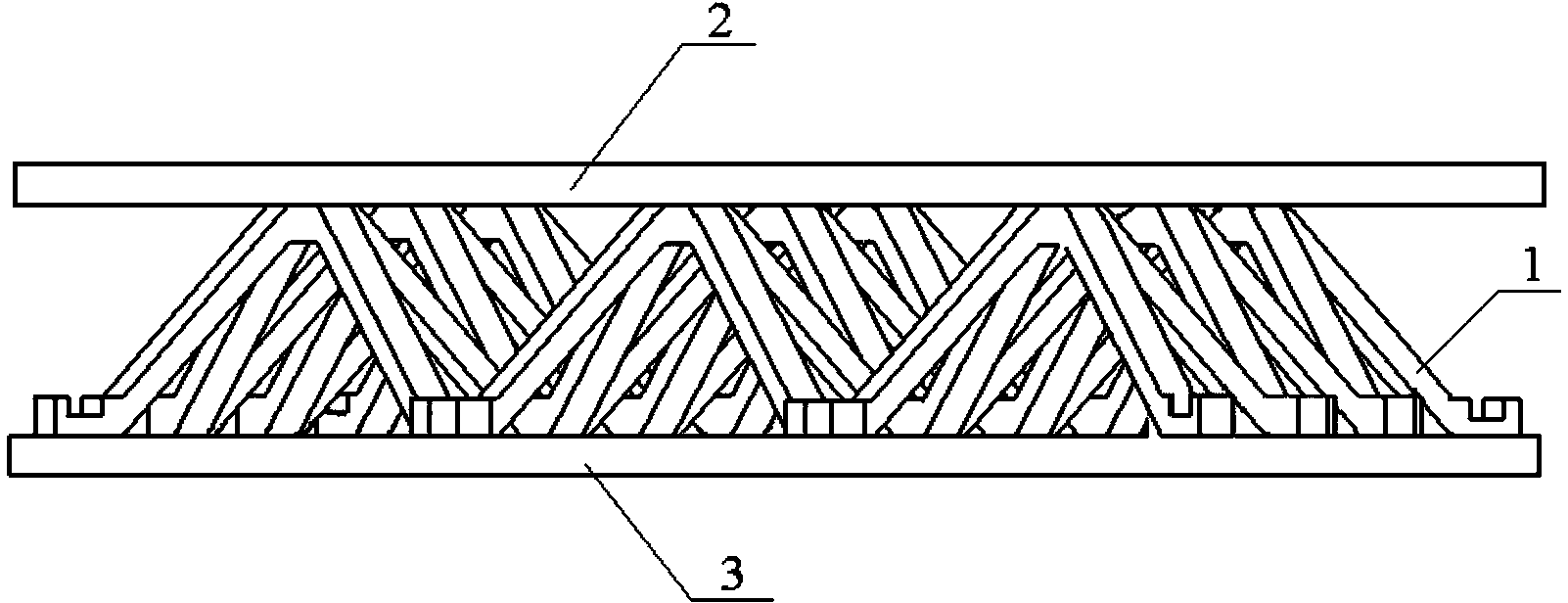

[0022] Specific embodiment 1: This embodiment is a metal pyramid-shaped lattice sandwich panel including a pyramid-shaped lattice core 1, a metal upper panel 2 and a metal lower panel 3;

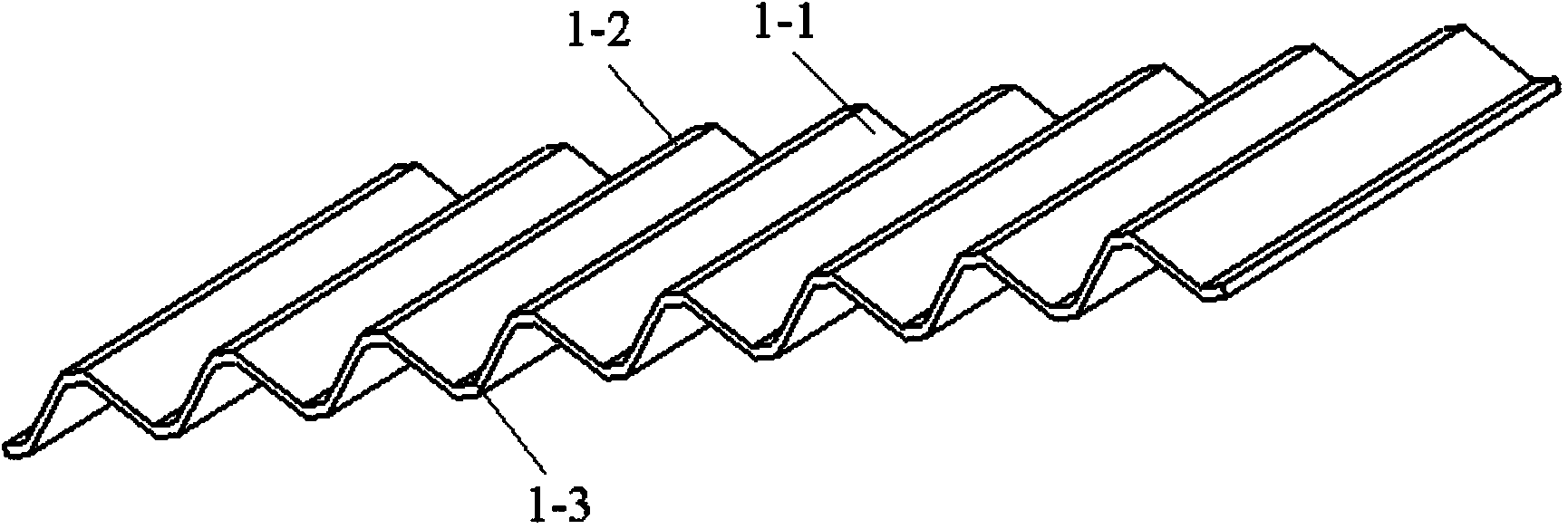

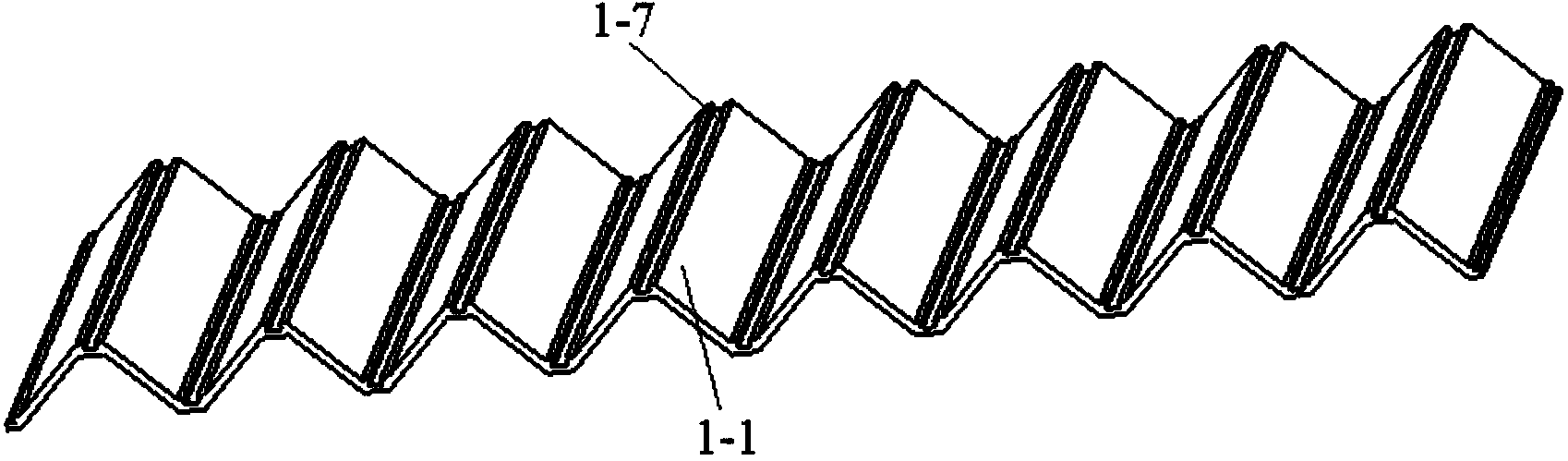

[0023] The pyramid-shaped lattice core 1 is composed of a plurality of metal pyramid-shaped lattice structure unit cells 4; each metal pyramid-shaped lattice structure unit cell 4 is a pyramid-shaped integral piece composed of four rods ; On the upper surface of each rod parallel to the horizontal plane, there are rectangular interlocking notches 1-7, or on the lower surface of each rod parallel to the horizontal plane, there are rectangular interlocking notches 1-7; The fixed supporting legs between two adjacent metal pyramid-shaped lattice structure unit cells 4 are fastened and fixed as a whole through rectangular interlocking slots 1-7 to form a pyramid-shaped lattice core 1;

[0024] The upper end faces of all metal pyramid-shaped lattice structure unit cells 4 in the pyramid-shaped lattice ...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and the first embodiment is: the upper end faces of all metal pyramid-shaped lattice structure unit cells 4 in the pyramid-shaped lattice core 1 are fixedly connected with the metal upper panel 2 through Connected by bonding or welding. The other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: the lower end surface of all metal pyramid-shaped lattice structure unit cells 4 in the pyramid-shaped lattice core 1 and the metal lower plate 3 The fixed connection is connected by bonding or welding. The other steps are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com