Bottle cutting device and cutting method

A cutting device and cutting piece technology, applied in the field of medical equipment, can solve the problems of high working intensity of medical staff, insufficient cutting depth, injury of medical staff, etc., and achieve the effects of reducing labor intensity, avoiding injury, and protecting personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

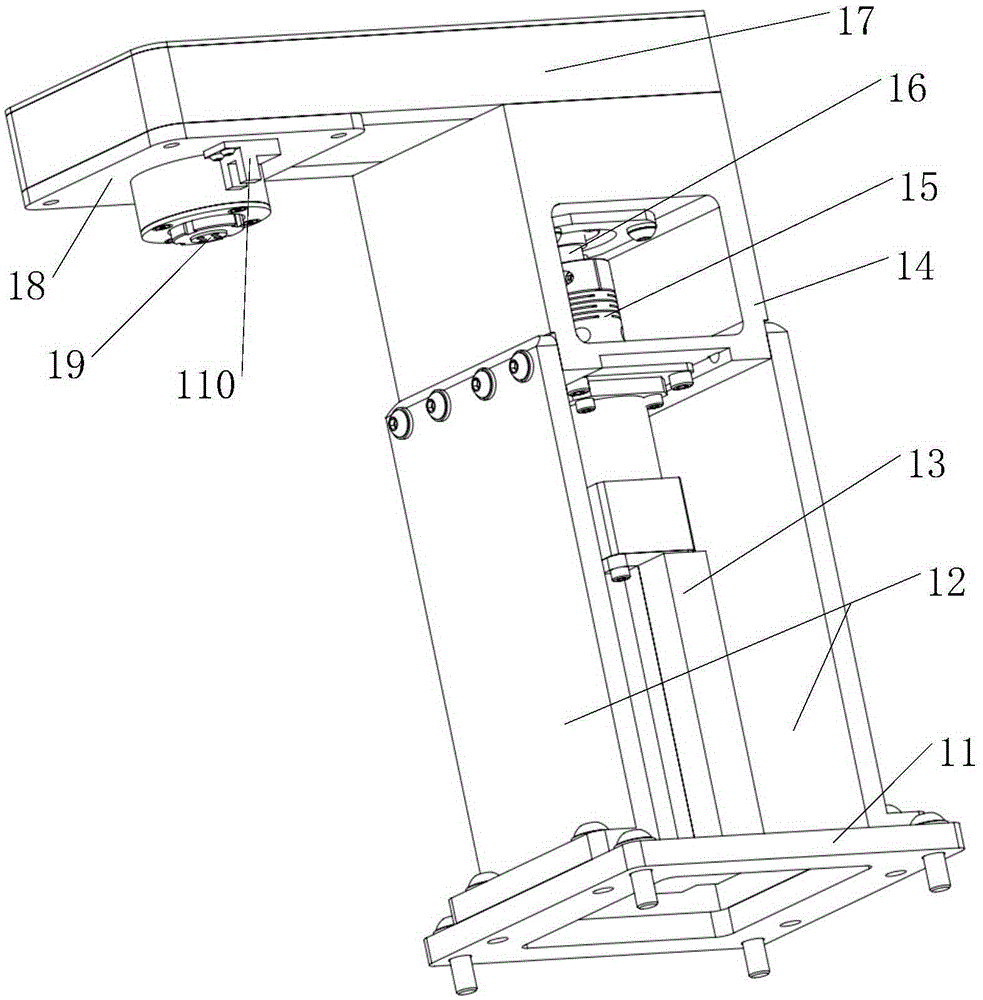

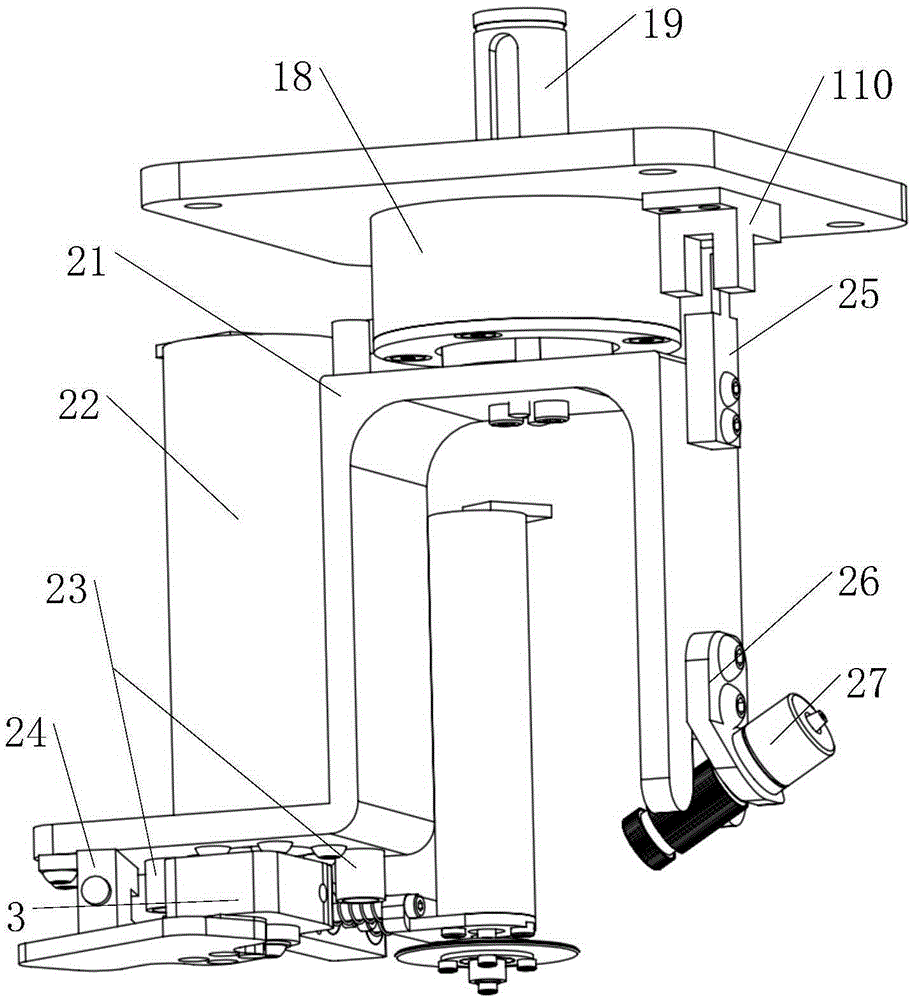

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] It should be understood that although the cutting device and cutting method of the present invention are described below with reference to the cutting of ampoules, this is by way of example only and the cutting device and cutting of the present invention are also applicable to cutting other items, such as other glass bottles and the like. It should also be understood that the cutting device and cutting method described below are only one specific embodiment of the present invention, rather than limiting the present invention; the scope of the present invention is not limited to the disclosed embodiments, but is defined by the claims.

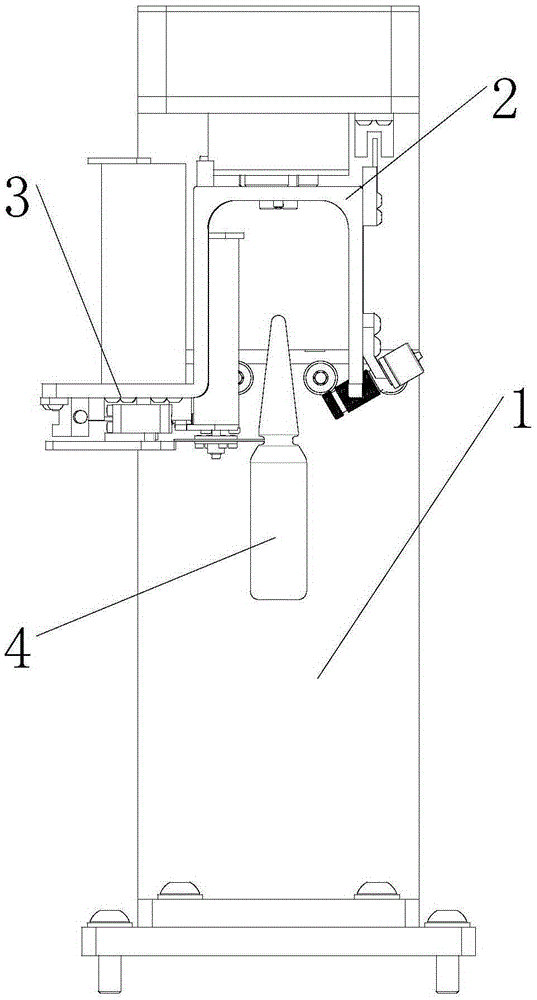

[0040] The invention relates to an economical and practical automatic bottle cutting device with high cutting precision, which is especially used in combination with machines requiring automatic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com