Preparation method of activated cokes with surface functional groups with directionally distributed polarities

A technology of surface functional groups and directional distribution, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of reducing the number of basic functional groups and the number of polar functional groups on the surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

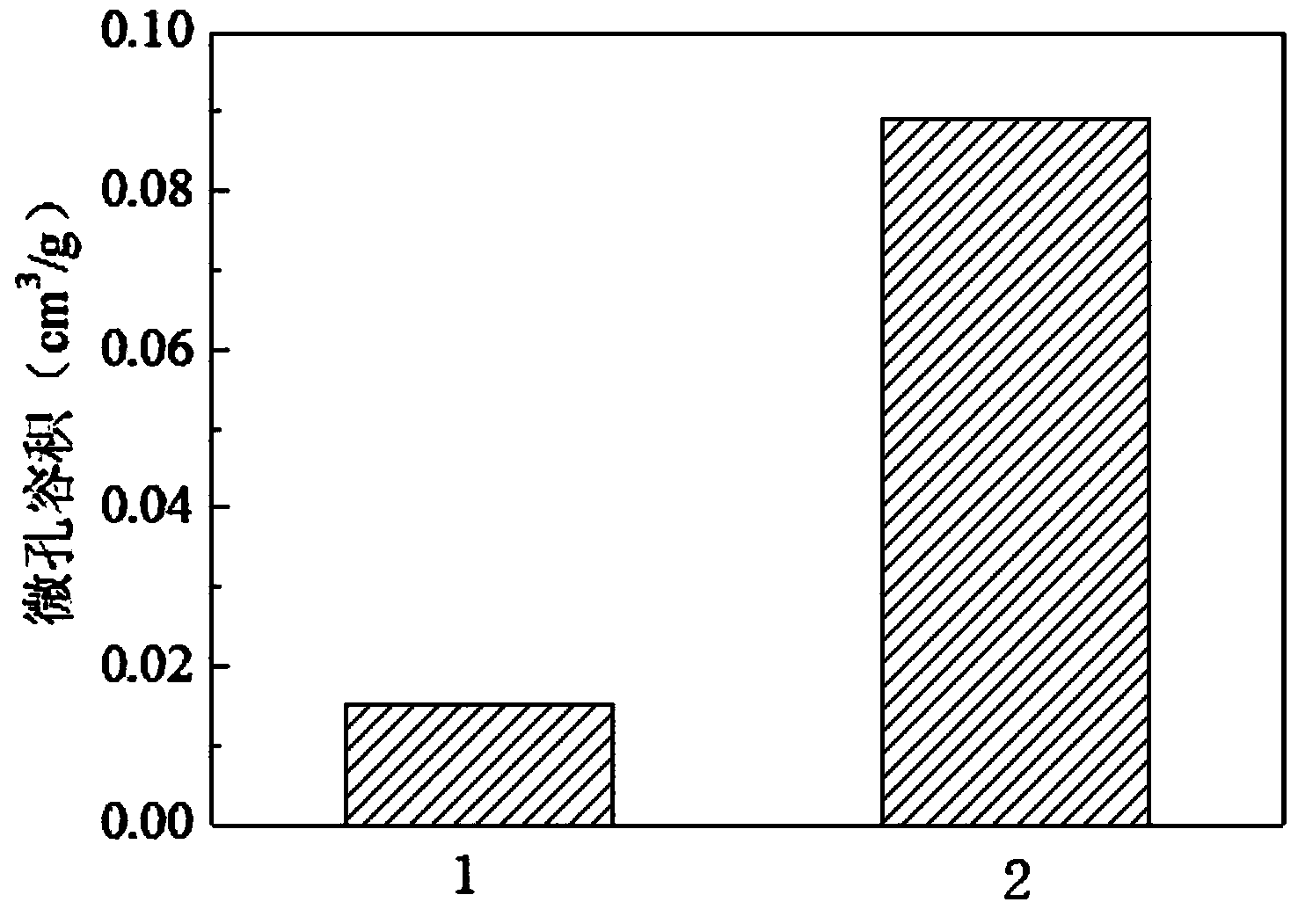

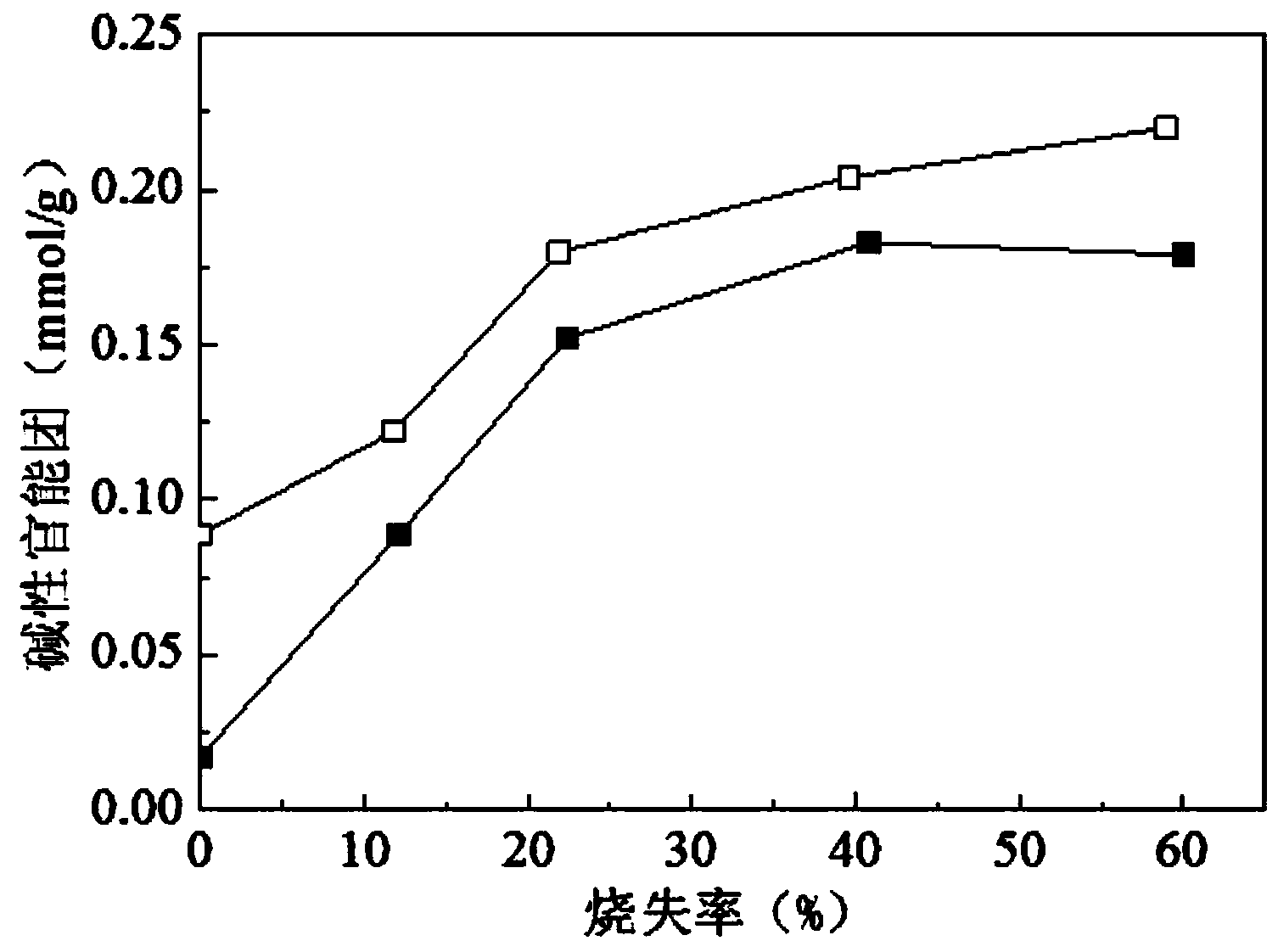

[0026] Specific implementation mode 1: In this implementation mode, the active coke preparation method with polarity and directional distribution of surface functional groups is realized according to the following steps:

[0027] 1. Crush the weakly cohesive coal and sieve it to obtain coal particles;

[0028] 2. Under the condition of air circulation, raise the temperature of the coal particles obtained in step 1 to 180°C-280°C, stay for 4h-10h for air pre-oxidation treatment, and obtain the coal particles after pre-oxidation treatment;

[0029] 3. Under the condition of isolating the air, heat the pre-oxidized coal particles obtained in step 2 to 700-800°C at a heating rate of 8°C / min-15°C / min, and the residence time is 0.5h-2h , to obtain carbonized material;

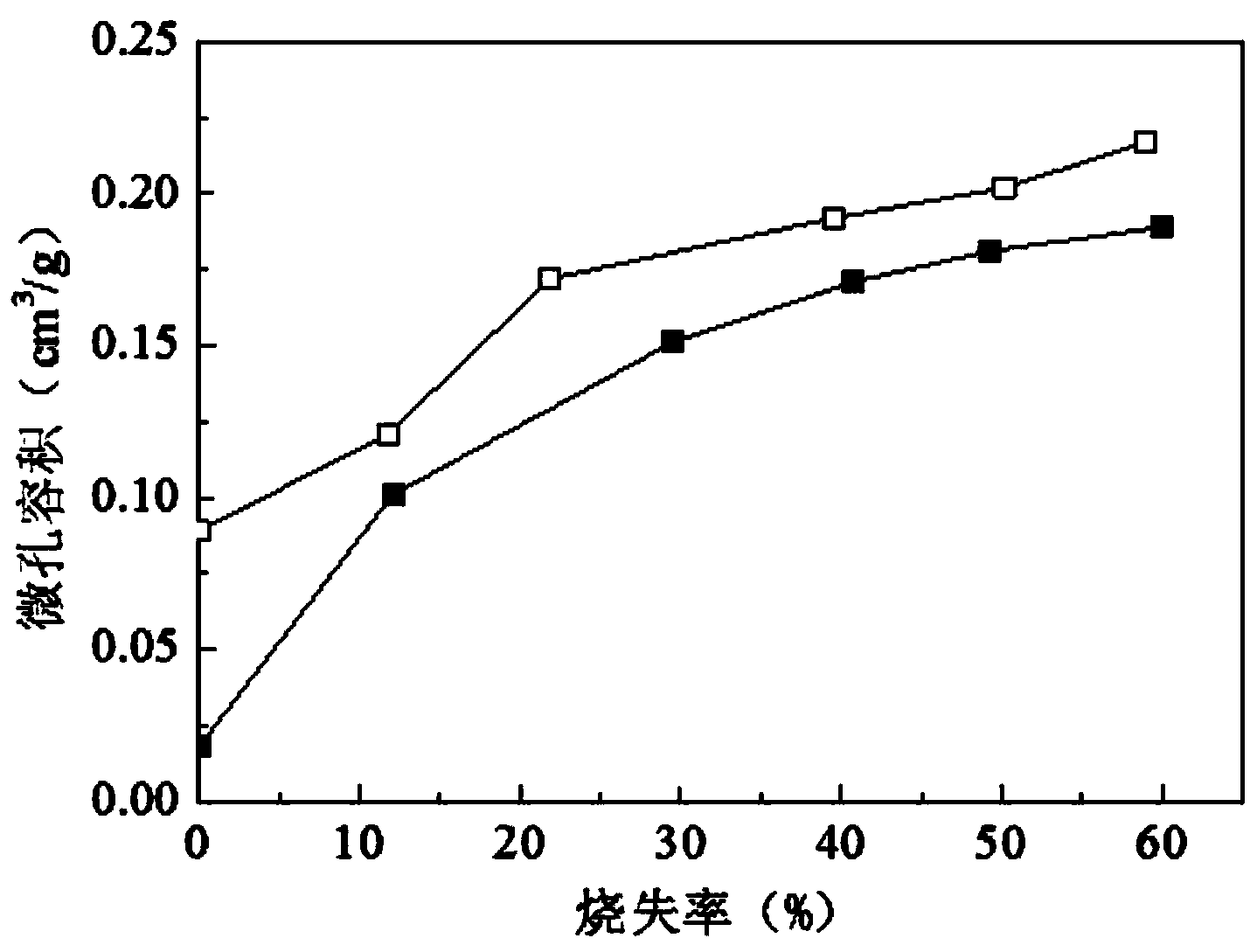

[0030] 4. Activate the carbonized material obtained in step 3, first use water vapor and O 2 The mixed gas formed is used as an activator and activated at 700°C to 850°C until the loss on ignition rate reaches 25% ...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that the weakly caking coal described in step 1 is Datong bituminous coal. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the particle size of the coal particles described in step 1 is 3 mm to 5 mm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com