Active coke preparation process

A preparation process and technology of activated coke, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of low adsorption desulfurization capacity and large usage, and achieve the effect of accelerating desulfurization reaction, developing pores, and increasing pore structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

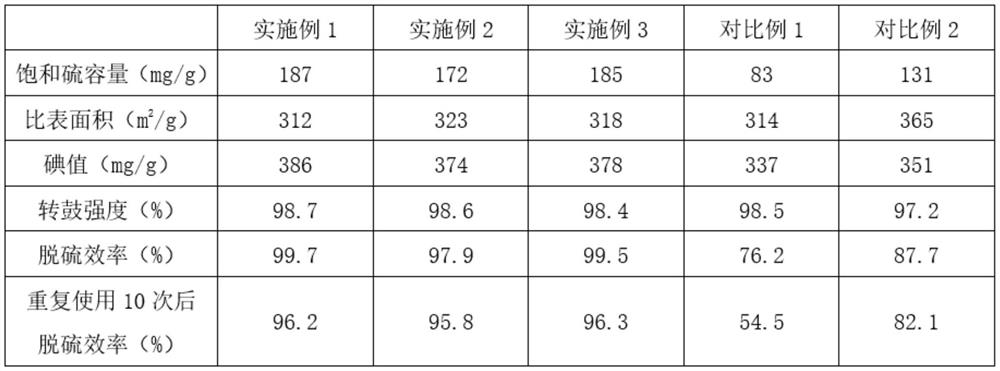

Examples

Embodiment 1

[0033] A process for preparing active coke, comprising the following steps:

[0034] Step 1, using biochar to prepare the primary product of activated coke;

[0035] Step 2, weighing diethyl nicotinamide and adding it to acetone, stirring until completely dissolved to obtain an activator;

[0036] Step 3, using the activator to treat the initial active coke product to obtain the active coke product.

[0037] Wherein, the biochar is obtained from agricultural by-products through biomass dry distillation; the agricultural by-products include rice husks, wheat straw, cottonseed husks, peanut shells, fruit shells, bagasse, fruit peels, vines and corn cobs. one or more.

[0038] The step 1 is specifically:

[0039] S1. After removing impurities, the biochar is pulverized and sieved to obtain biochar powder with a particle size of 0.5-1mm;

[0040] S2. Add the biomass charcoal powder into a sealed reaction kettle, bake it in the presence of air, and cool it to room temperature w...

Embodiment 2

[0048] A process for preparing active coke, comprising the following steps:

[0049] Step 1, using biochar to prepare the primary product of activated coke;

[0050] Step 2, weighing diethyl nicotinamide and adding it to acetone, stirring until completely dissolved to obtain an activator;

[0051] Step 3, using the activator to treat the initial active coke product to obtain the active coke product.

[0052] Wherein, the biochar is obtained from agricultural by-products through biomass dry distillation; the agricultural by-products include rice husks, wheat straw, cottonseed husks, peanut shells, fruit shells, bagasse, fruit peels, vines and corn cobs. one or more.

[0053] The step 1 is specifically:

[0054] S1. After removing impurities, the biochar is pulverized and sieved to obtain biochar powder with a particle size of 0.5-1mm;

[0055] S2. Add the biomass charcoal powder into a sealed reaction kettle, bake it in the presence of air, and cool it to room temperature w...

Embodiment 3

[0063] A process for preparing active coke, comprising the following steps:

[0064] Step 1, using biochar to prepare the primary product of activated coke;

[0065] Step 2, weighing diethyl nicotinamide and adding it to acetone, stirring until completely dissolved to obtain an activator;

[0066] Step 3, using the activator to treat the initial active coke product to obtain the active coke product.

[0067] Wherein, the biochar is obtained from agricultural by-products through biomass dry distillation; the agricultural by-products include rice husks, wheat straw, cottonseed husks, peanut shells, fruit shells, bagasse, fruit peels, vines and corn cobs. one or more.

[0068] The step 1 is specifically:

[0069] S1. After removing impurities, the biochar is pulverized and sieved to obtain biochar powder with a particle size of 0.5-1mm;

[0070] S2. Add the biomass charcoal powder into a sealed reaction kettle, bake it in the presence of air, and cool it to room temperature w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com