Tang Jun glaze and its production process

A Tang Jun glaze and yellow feldspar technology, applied in the new Tang Jun glaze and its production technology field, can solve the problems of uneven glaze, poor appreciation, high water absorption, and achieve bright color transition, rich glaze, and strong sense of hierarchy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

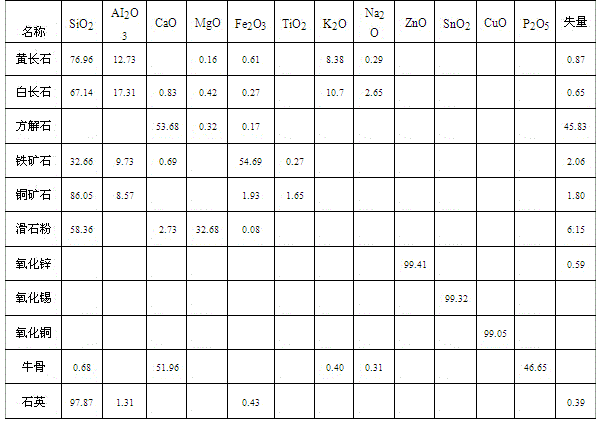

[0046] The new Tangjun glaze uses yellow feldspar, white feldspar, calcite, quartz, copper ore, and iron ore as surface glaze raw materials. The weight percentage of each raw material is: yellow feldspar 48%, white feldspar 17%, and calcite 3%. , quartz 16%, copper ore 6%, iron ore 10%;

[0047] Yellow feldspar, white feldspar, calcite, quartz, talcum powder, copper ore, zinc oxide, tin oxide, copper oxide and bovine bone are used as bottom glaze raw materials, and the weight percentages of each raw material are: 50% of yellow feldspar, 8% of white feldspar %, Calcite 18%, Quartz 11%, Talc 5%, Copper Ore 4%, Zinc Oxide 2%, Tin Oxide 0.5%, Copper Oxide 0.5% and Bovine Bone 1%.

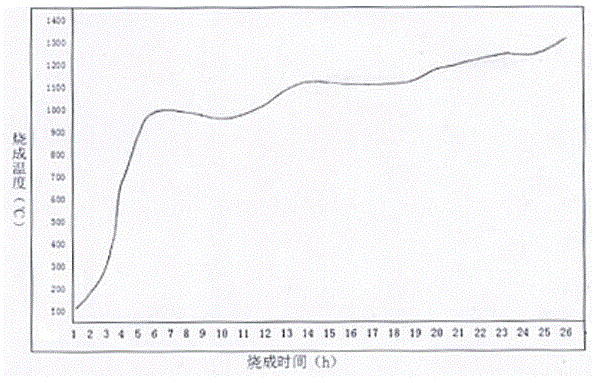

[0048] The preparation method of novel Tang Jun glaze:

[0049] Step 1. After pulverizing the bottom glaze raw materials, mix them into the ball mill according to the above ratio. Raw materials: ball stone: water = 1: 1.5: 0.36, start wet grinding for 16 hours, and pass the wet-milled slurry through a ...

Embodiment 2

[0055] The new Tangjun glaze uses yellow feldspar, white feldspar, calcite, quartz, copper ore, and iron ore as surface glaze raw materials. The weight percentage of each raw material is: yellow feldspar 50%, white feldspar 15%, and calcite 4%. , quartz 15%, copper ore 5%, iron ore 11%;

[0056] Use yellow feldspar, white feldspar, calcite, quartz, talcum powder, copper ore, zinc oxide, tin oxide, copper oxide and bovine bone as bottom glaze raw materials, the weight percentage of each raw material addition is: yellow feldspar 53%, white feldspar 10% %, Calcite 16%, Quartz 10%, Talc 3%, Copper Ore 3%, Zinc Oxide 3%, Tin Oxide 0.5%, Copper Oxide 0.5% and Bovine Bone 1%.

[0057] The preparation method of novel Tang Jun glaze:

[0058] Step 1. After pulverizing the bottom glaze raw materials, mix them into the ball mill according to the above ratio, raw materials: ball stone: water = 1: 1.5: 0.38, start the wet grinding for 18 hours, and pass the wet-milled slurry through a 250...

Embodiment 3

[0064] The new Tangjun glaze uses yellow feldspar, white feldspar, calcite, quartz, copper ore, and iron ore as surface glaze raw materials. The weight percentage of each raw material is: yellow feldspar 53%, white feldspar 14%, and calcite 2%. , quartz 14%, copper ore 8%, iron ore 9%;

[0065]Yellow feldspar, white feldspar, calcite, quartz, talcum powder, copper ore, zinc oxide, tin oxide, copper oxide and bovine bone are used as bottom glaze raw materials, and the weight percentages of each raw material are: yellow feldspar 55%, white feldspar 12% %, Calcite 14%, Quartz 9%, Talc 2%, Copper Ore 2%, Zinc Oxide 4%, Tin Oxide 0.5%, Copper Oxide 0.5% and Bovine Bone 1%.

[0066] The preparation method of novel Tang Jun glaze:

[0067] Step 1. After pulverizing the bottom glaze raw materials, mix them into the ball mill according to the above ratio, raw materials: ball stone: water = 1: 1.5: 0.4, start the wet grinding for 20 hours, and pass the wet-milled slurry through a 200-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com