A method of firing imitation Junhong glaze by in-situ vapor deposition method

A vapor deposition method and red glaze technology, which is applied in the field of firing imitation Junhong glaze by in-situ vapor deposition method, can solve the unfavorable mass production of imitation Junhong glaze daily-use enamel, art enamel, firing failure, smoke, etc. Problems can be achieved by improving the glaze firing temperature and glaze effect, improving the firing rate, and reducing the firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

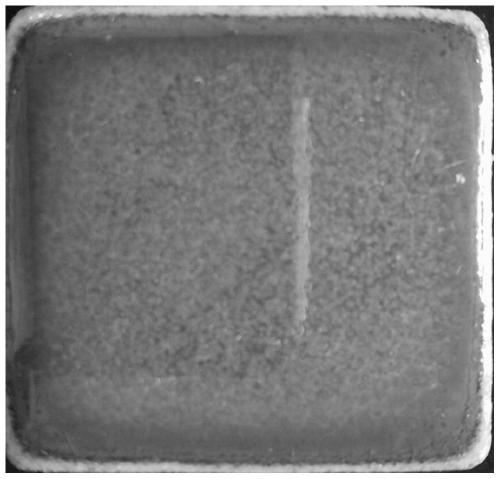

Image

Examples

Embodiment 1

[0035] A method for firing imitation Junhong glaze by in-situ vapor deposition method, comprising the steps of:

[0036] Step 1, take the following components by mass percentage: 20% potassium feldspar, 20% albite, 20% quartz, 25% calcite, 10% talc, 5% nano-alumina, and mix the above components evenly to obtain base glaze;

[0037] Mix basic glaze, water, and alumina grinding balls according to the mass ratio of 1.0:1.2:2.0, and then ball mill at a speed of 200r / min for 24 hours. Adjust the specific gravity of the slurry after passing through the mesh sieve to 1.55g / cm 3 , the basic glaze slurry is obtained after the preparation is completed;

[0038] Step 2: Put the ceramic green body into a muffle furnace, keep it warm at 880°C for 30 minutes under the condition of air atmosphere, and after the heat preservation is completed, cool it down to room temperature with the furnace to obtain a bisque-fired ceramic green body;

[0039] Step 3: Apply the basic glaze slurry prepare...

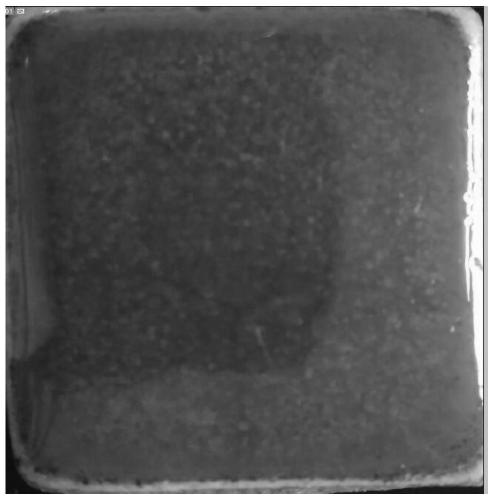

Embodiment 2

[0045] A method for firing imitation Junhong glaze by in-situ vapor deposition method, comprising the steps of:

[0046] Step 1, take the following components by mass percentage: 25% potassium feldspar, 25% albite, 15% quartz, 15% calcite, 10% talc, 10% nano-alumina, and mix the above components evenly to obtain base glaze;

[0047] Mix basic glaze, water, and alumina grinding balls according to the mass ratio of 1.0:1.2:2.0, and then ball mill at a speed of 200r / min for 24 hours. Adjust the specific gravity of the slurry after passing through the mesh sieve to 1.65g / cm 3 , the basic glaze slurry is obtained after the preparation is completed;

[0048] Step 2: Put the ceramic green body into a muffle furnace, keep it warm at 880°C for 30 minutes under the condition of air atmosphere, and after the heat preservation is completed, cool it down to room temperature with the furnace to obtain a bisque-fired ceramic green body;

[0049] Step 3, apply the basic glaze slurry prepared...

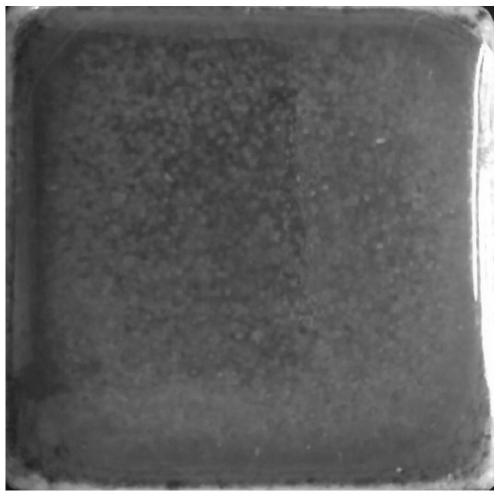

Embodiment 3

[0055] A method for firing imitation Junhong glaze by in-situ vapor deposition method, comprising the steps of:

[0056] Step 1, take the following components by mass percentage: 22.5% potassium feldspar, 22.5% albite, 15% quartz, 20% calcite, 10% talc, 10% nano-alumina, and mix the above components evenly to obtain base glaze;

[0057] Mix basic glaze, water, and alumina grinding balls according to the mass ratio of 1.0:1.2:2.0, and then ball mill at a speed of 200r / min for 24 hours. Adjust the specific gravity of the slurry after passing through the mesh sieve to 1.60g / cm 3 , the basic glaze slurry is obtained after the preparation is completed;

[0058] Step 2: Put the ceramic green body into a muffle furnace, keep it warm at 880°C for 30 minutes under the condition of air atmosphere, and after the heat preservation is completed, cool it down to room temperature with the furnace to obtain a bisque-fired ceramic green body;

[0059] Step 3: Apply the basic glaze slurry pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com