TMSOTf (trimethylsilyl trifluoromethanesulfonate) purifying method

A technology of trimethylsilyl trifluoromethanesulfonate and trimethylsilyl fluoromethanesulfonate, which is applied in the field of purification of trimethylsilyl trifluoromethanesulfonate, to achieve cost reduction and complete impurity recovery and treatment measures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

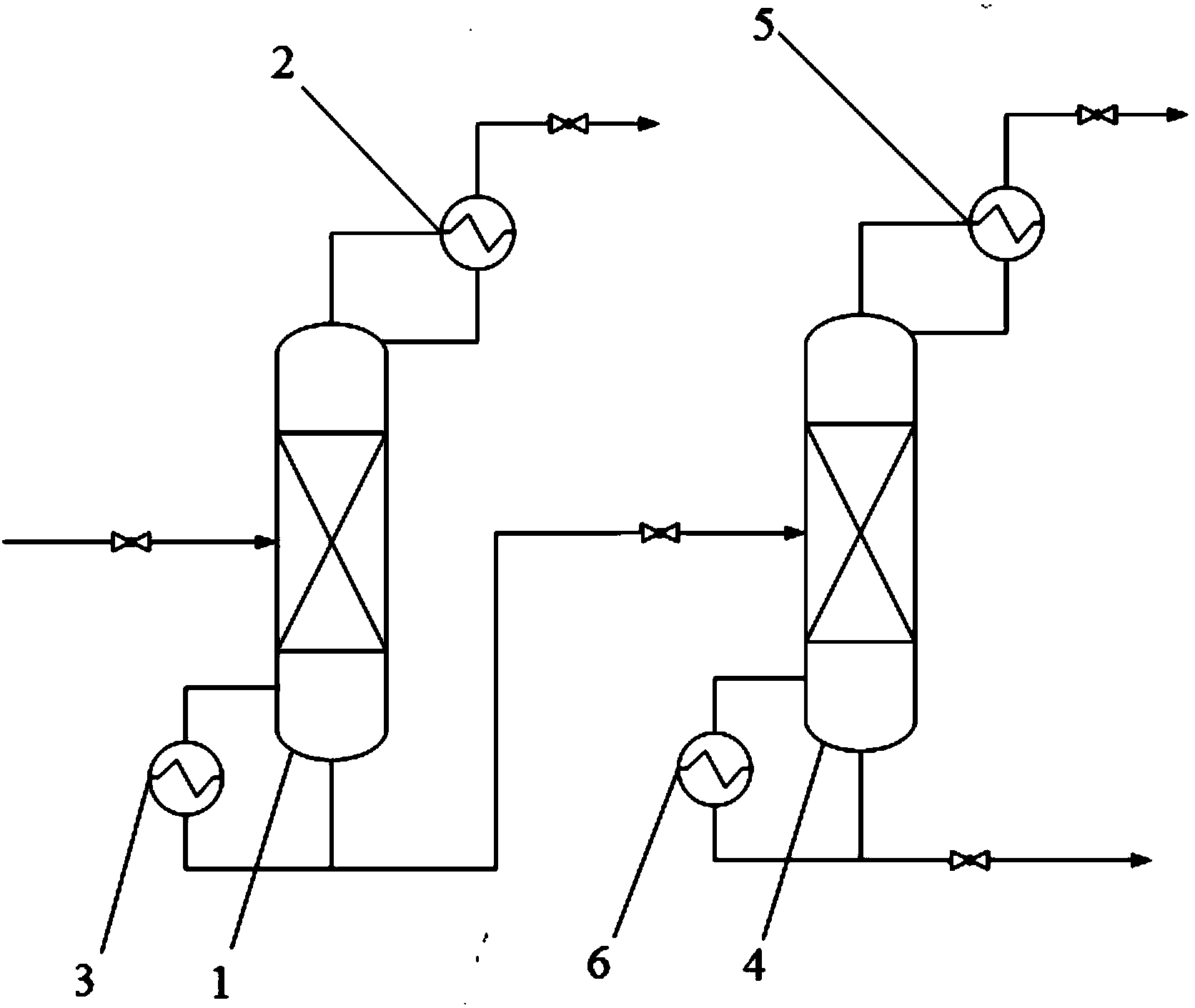

[0031] In the rectification device adopted in this embodiment, the diameter of the rectification tower is 20mm, the height is 2m, and the nickel Pall ring filler is filled inside, and the specific surface area of the filler is 80m 2 / m 3 , the packing form is random.

[0032] A method for purifying trimethylsilyl trifluoromethanesulfonate, the method steps are as follows:

[0033] (1) Removal of light component impurity HCl

[0034] The trimethylsilyl trifluoromethanesulfonate crude product is imported in the HCl-removing rectification tower 1, the pressure of the tower bottom of the said rectification tower 1 is controlled to be -0.098MPa, the temperature of the tower bottom is 40°C, and the temperature of the tower top is 20°C, the feeding amount of the crude product is 5m 3 / h, the reflux ratio is 200, and the gas rich in light component impurity HCl enters condenser A 2 after being discharged from the tower top, and a part of liquid phase is refluxed to described rect...

Embodiment 2

[0041] In the rectification device adopted in this embodiment, the diameter of the rectification tower is 100mm, the height is 10m, and the inside is filled with Monel Pall ring packing, and the specific surface area of the packing is 500m 2 / m 3 , the packing form is random.

[0042] A method for purifying trimethylsilyl trifluoromethanesulfonate, the method steps are as follows:

[0043] (1) Removal of light component impurity HCl

[0044] The trimethylsilyl trifluoromethanesulfonate crude product is introduced into the HCl-removing rectification tower 1, the pressure of the bottom of the distillation tower 1 is controlled to be -0.002MPa, the temperature of the bottom of the tower is 138 ° C, and the temperature of the top of the tower is 120°C, the feeding amount of the crude product is 500m 3 / h, the reflux ratio is 2000, and the gas rich in light component impurity HCl enters condenser A2 after being discharged from the tower top, and a part of liquid phase is reflu...

Embodiment 3

[0051] In the rectification device adopted in this embodiment, the diameter of the rectification tower is 50mm, the height is 5m, and the interior is filled with stainless steel Pall ring packing, and the specific surface area of the packing is 253m 2 / m 3 , the packing form is regular.

[0052] A method for purifying trimethylsilyl trifluoromethanesulfonate, the method steps are as follows:

[0053] (1) Removal of light component impurity HCl

[0054] The trimethylsilyl trifluoromethanesulfonate crude product is imported in the HCl-removing rectification tower 1, the pressure of the bottom of the distillation tower 1 is controlled to be -0.053MPa, the temperature of the bottom of the tower is 98 ° C, and the temperature of the top of the tower is 70°C, the feed amount of the crude product is 210m 3 / h, the reflux ratio is 830, and the gas rich in light component impurity HCl enters condenser A2 after being discharged from the tower top, and a part of liquid phase is refl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com