Synergistic denitrification composite suspension filler, its preparation method and application

A suspended filler and denitrification technology, applied in the field of water treatment, can solve the problems of low denitrification efficiency and low filler utilization rate, and achieve good denitrification performance, enhanced removal effect, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

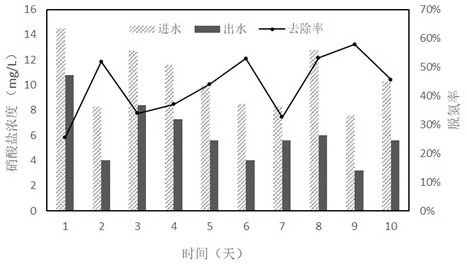

Embodiment 1

[0044] This example provides a heterotrophic sulfur autotrophic synergistic denitrification composite suspension filler to strengthen the denitrification of sewage in the anoxic section of municipal sewage treatment. The filler is granular with a particle size of 6 mm and a specific gravity of 0.95 g / cm 3 , porosity is 46.8%; described filler contains elemental sulfur, coal powder, calcium carbonate, and described elemental sulfur is sulfur, and the mass ratio of sulfur, coal powder, calcium carbonate is 3.5:3:1.5; With 80-200 purpose Egg shell powder is the raw material to form the calcium carbonate material in the filler.

[0045] Among them, coal powder is used as the carbon source of the heterotrophic denitrifying bacteria group, and the heterotrophic denitrifying bacteria group is a fungal community mainly composed of white rot fungi as the first-level community after domestication, and the metabolites of the fungal community are used as nutrients. Denitrification seconda...

Embodiment 2

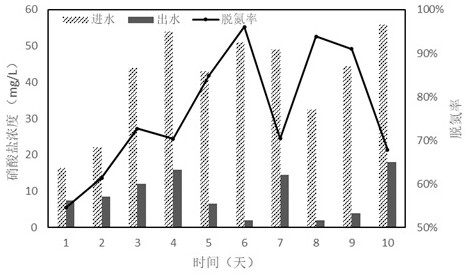

[0057] This example provides a heterotrophic sulfur autotrophic synergistic denitrification composite suspension filler, which is used in rural sewage treatment composite equipment. The filler is particles with a particle size of 5 mm and a specific gravity of 0.90 g / cm 3 , porosity 52.5%; Contain elemental sulfur, coal powder, calcium carbonate in the described packing, described elemental sulfur is sulfur, the mass ratio of sulfur, coal powder, calcium carbonate is 3:3:1.5; With 80-200 purpose Egg shell powder is the raw material to form the calcium carbonate material in the filler.

[0058] Among them, coal powder is used as the carbon source of the heterotrophic denitrifying bacteria group, and the heterotrophic denitrifying bacteria group is a fungal community mainly composed of white rot fungi as the first-level community after domestication, and the metabolites of the fungal community are used as nutrients. Denitrification secondary community dominated by Tauerella, Pse...

Embodiment 3

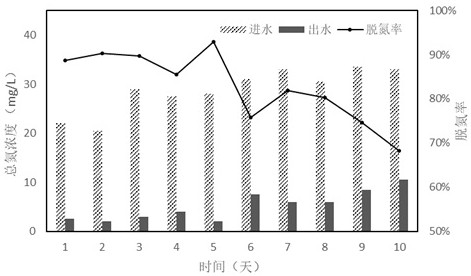

[0070] This example provides a heterotrophic sulfur autotrophic synergistic high-efficiency denitrification suspension filler, which is used in equipment such as biofilters and biological fluidized beds. The filler is a particle with a particle size of 8 mm and a specific gravity of 1.01 g / cm 3 , porosity 46.2%; Contain elemental sulfur, coal powder, calcium carbonate in the described packing, described elemental sulfur is sulfur, the mass ratio of sulfur, coal powder, calcium carbonate is 2:1.5:1; With 80-200 purpose Egg shell powder is the raw material to form the calcium carbonate material in the filler.

[0071] Among them, coal powder is used as the carbon source of the heterotrophic denitrifying bacteria group, and the heterotrophic denitrifying bacteria group is a fungal community mainly composed of white rot fungi as the first-level community after domestication, and the metabolites of the fungal community are used as nutrients. Denitrification secondary community domi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com