Method and system for separating precipitate from liquid

A technology for liquid separation and sedimentation, applied in solid separation, flotation, etc., can solve the problems of difficult removal of fiber coils, troublesome removal of sediments, and difficulty in removing biopolymer sediments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the present application, corresponding or similar features are indicated by corresponding or similar reference numerals.

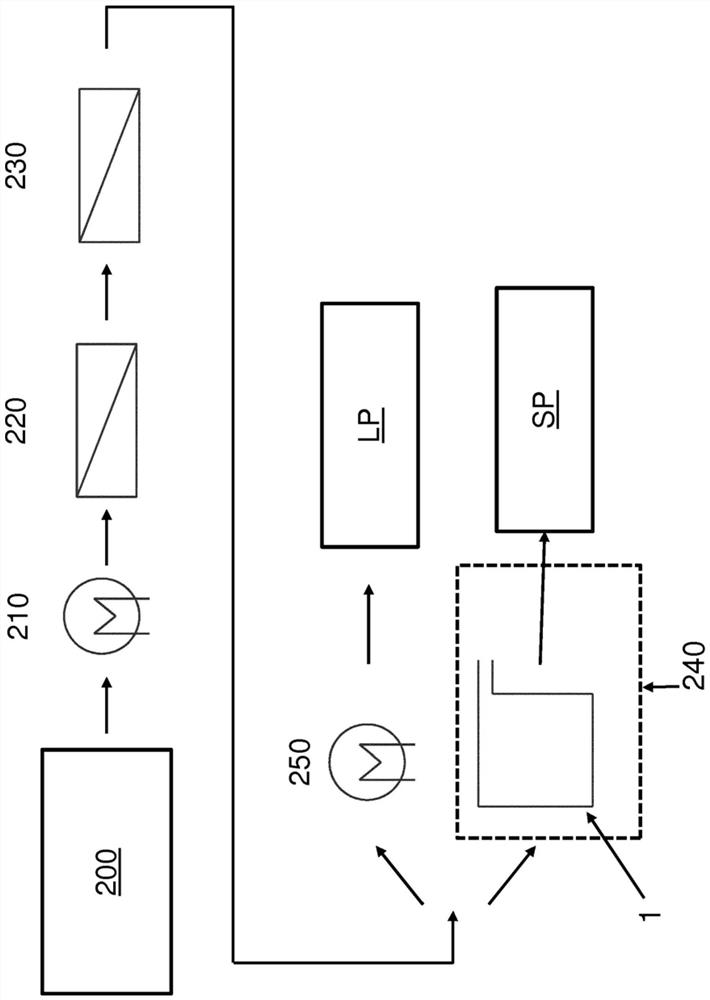

[0030] As the skilled artisan will appreciate, the precipitate can be formed in various ways. An example is biopolymer precipitation as part of biopolymer production. figure 1 An exemplary process for biopolymer precipitation is schematically depicted. It may include steps such as:

[0031] - a fermentation step 200 for providing a fermentation broth;

[0032] - a first ultra high temperature (UHT) treatment step 210;

[0033] - one or more stages of filtration, for example comprising a filtration step 220 and an ultrafiltration step 230, for example using a filter press;

[0034] - a precipitation step 240 to provide a solid product SP; and

[0035] - A second ultra high temperature (UHT) treatment step 250 to provide a liquid product LP.

[0036] Typically, a precipitation step 240 is performed to recover the water-soluble biopolymer from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com