Method for removing carbon tetrafluoride foreign matter in nitrogen trifluoride gas

A carbon tetrafluoride and nitrogen trifluoride technology, applied in the field of CF4 impurities, can solve the problems of high consumption of inert gas, low efficiency, difficult industrialization implementation, etc., and achieve the effect of complete recycling measures and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

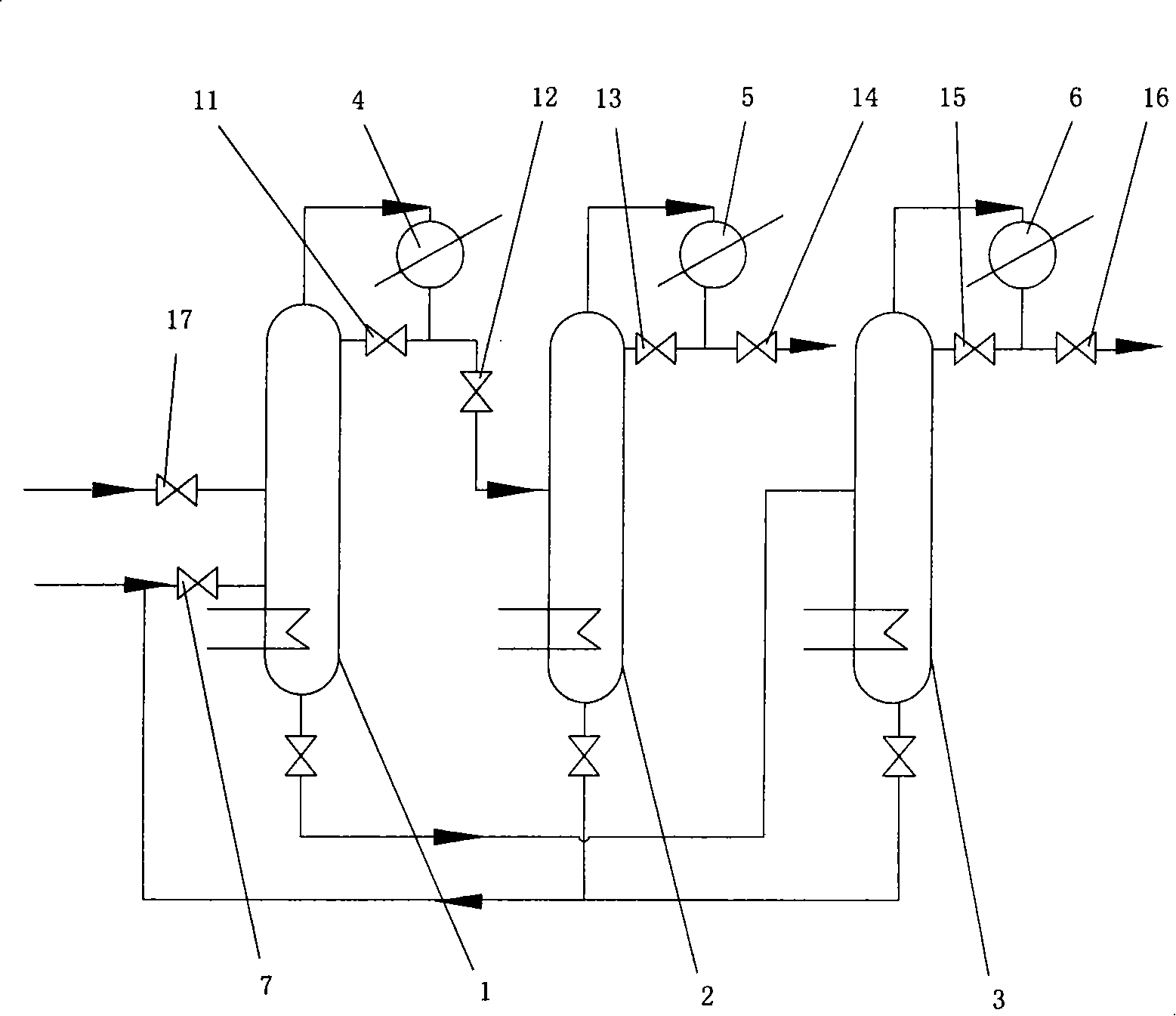

[0018] A rectification column with a diameter of 50 mm and a height of 5 m is filled with nickel Pall ring packing. The specific surface area of the filler is 364m2 / m3, and the filler form is random.

[0019] Raw material gas NF3 total amount is 300kg among the present invention, and wherein CF Content is 500ppm, this raw material gas is added in No. 1 rectifying tower 1 by valve 17, adds entrainer hydrogen chloride by valve 7 under this feeding position simultaneously ( HCl), the addition is 15kg. Control the working pressure of the rectification tower between 0.1MPa and 1.6MPa, preferably 0.2MPa. In this pressure range, the lowest azeotrope between impurity gas and entrainer can be formed well. If it is too low or too high, the azeotrope cannot be formed, and the effect of azeotropic distillation to remove impurity gas cannot be achieved. The bottom temperature of the tower is -100°C, the top temperature is -120°C, and the reflux ratio is controlled at 1000. If the reflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com