Fluidized bed gasification process

A technology for fluidized bed gasification and fluidized bed gasification furnace, which is applied in the field of gasification and can solve the problems of high carbon content and low effective composition of coal gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

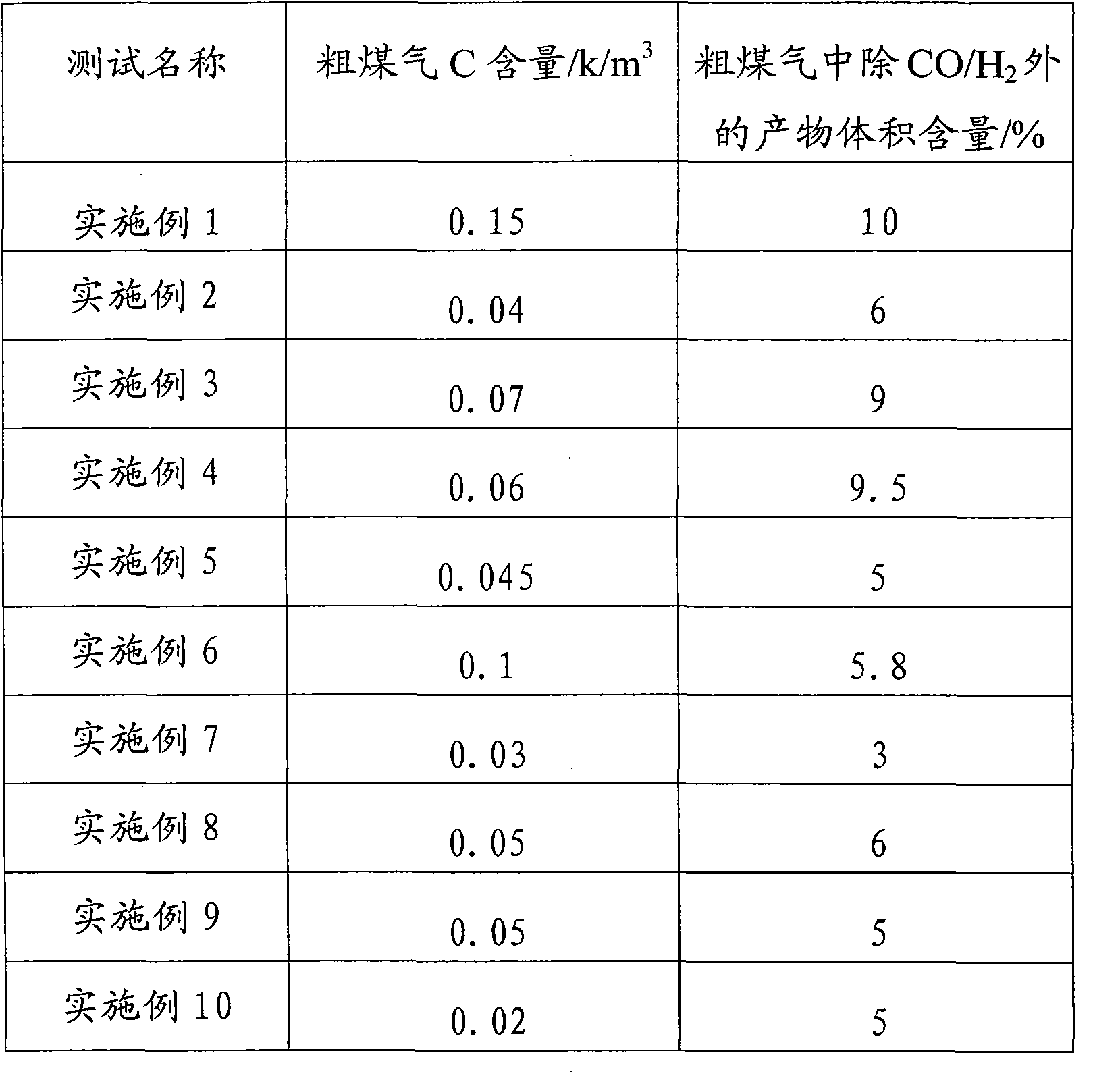

Examples

Embodiment 1

[0028] A kind of fluidized bed gasification process of the present invention, comprises the steps:

[0029] (1) take lignite as raw material, first crushing and screening are carried out to lignite, and the pulverized coal that obtains particle diameter is 3-4mm is stand-by;

[0030] (2) Carry out second crushing and screening to lignite to obtain pulverized coal with a particle diameter of 7-8mm for use;

[0031] (3) get the pulverized coal 12.5kg that obtains in step (1), get the pulverized coal 50kg in the step (2), in above-mentioned pulverized coal, spray active agent respectively, described active agent is the H that concentration is 50wt%. 3 BO 3 Aqueous solution (containing H 3 BO 3 1kg) and 60wt% aqueous solution (containing MgCl 2 1.083kg) of the mixture;

[0032] (4) drying the pulverized coal after spraying the active agent at 50 degrees Celsius for 1 hour;

[0033] (5) Choose oxygen as the gasification agent to carry out oven treatment on the fluidized bed g...

Embodiment 2

[0037] A kind of fluidized bed gasification process of the present invention, comprises the steps:

[0038] (1) take lignite as raw material, first crushing and screening are carried out to lignite, and the pulverized coal that obtains particle diameter is 3-4mm is stand-by;

[0039] (2) Carry out second crushing and screening to lignite to obtain pulverized coal with a particle diameter of 7-8mm for use;

[0040] (3) get the pulverized coal 25kg that obtains in step (1), get the pulverized coal 50kg in the step (2), in above-mentioned pulverized coal, spray active agent respectively, described active agent is the H that concentration is 50wt%. 3 BO 3 Aqueous solution (containing H 3 BO 3 2kg) and 60wt% CaCl 2 Aqueous solution (contains CaCl 2 3kg) of the mixture;

[0041] (4) Dry the pulverized coal after spraying the active agent at 60 degrees Celsius for 2.5 hours;

[0042] (5) Choose water vapor as the gasification agent to carry out oven treatment on the fluidized ...

Embodiment 3

[0046] A kind of fluidized bed gasification process of the present invention, comprises the steps:

[0047] (1) take lignite as raw material, first crushing and screening are carried out to lignite, and the pulverized coal that obtains particle diameter is 3-4mm is stand-by;

[0048](2) Carry out second crushing and screening to lignite to obtain pulverized coal with a particle diameter of 7-8mm for use;

[0049] (3) get the pulverized coal 30kg that obtains in step (1), get the pulverized coal 50kg in the step (2), in above-mentioned pulverized coal, spray active agent respectively, described active agent is the H that concentration is 60wt%. 3 BO 3 Aqueous solution (containing H 3 BO 3 1kg) and 50wt% of MgCl 2 Aqueous solution (containing MgCl 2 1.67kg) of the mixture;

[0050] (4) Dry the pulverized coal after spraying the active agent at 60 degrees Celsius for 2.5 hours;

[0051] (5) Select the mixture of oxygen and water vapor as the gasification agent to carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com