Device for corrosion prevention of steel structure splash zone with cathode protection

A technology for corrosion protection and cathodic protection is applied in the field of devices for corrosion protection in the splash zone of a steel structure with cathodic protection. Low and convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

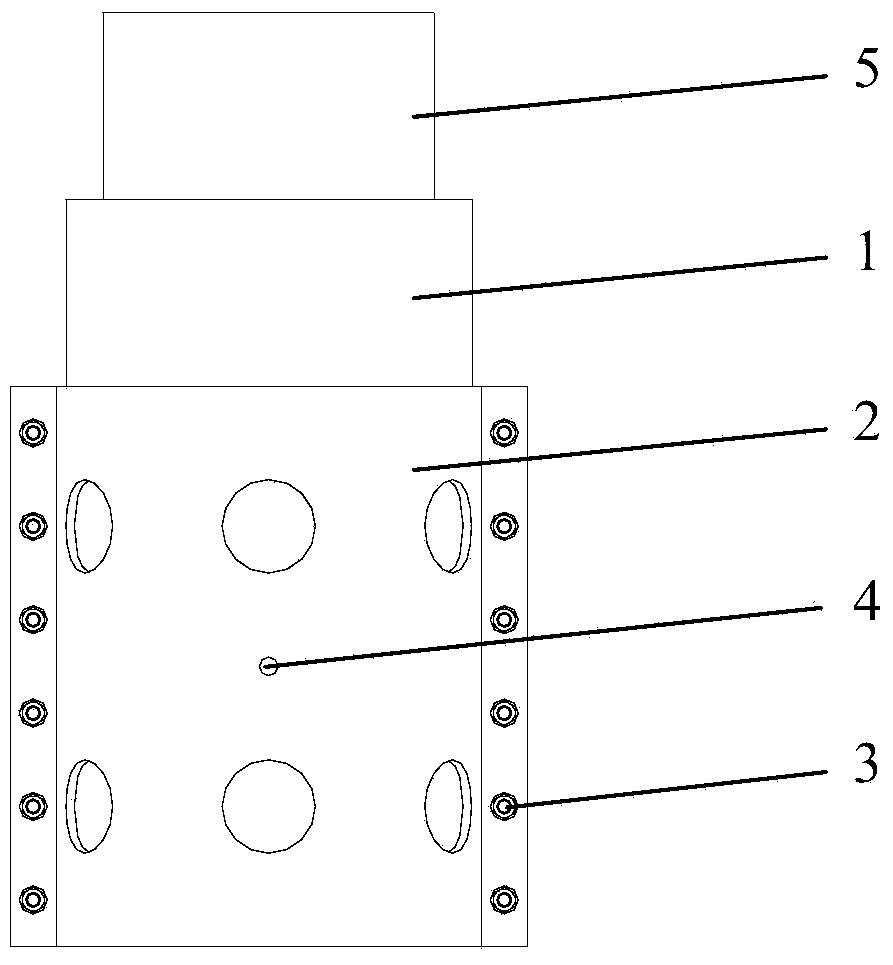

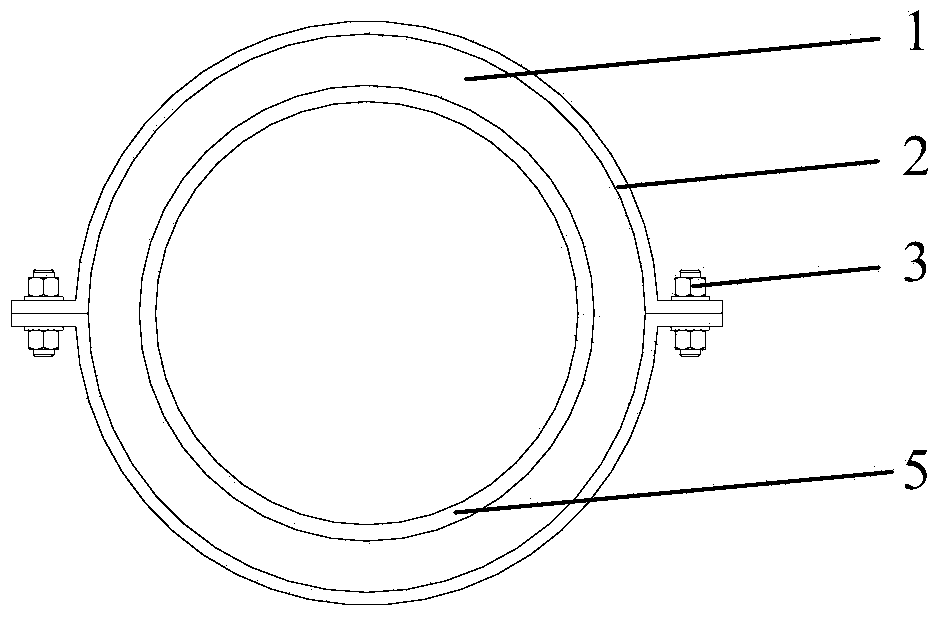

[0020] see figure 1 and figure 2 , a device for corrosion protection in the splash zone of a cathodically protected steel structure, comprising a layer of water-absorbing material 1 coated on the surface of the splash zone of a steel structure 5, the layer of water-absorbing material 1 is fixed by a hoop 2, and the hoop 2 is provided with hollow structure.

[0021] Principle of the present invention:

[0022] Due to the low seawater immersion rate in the steel structure splash area, the cathodic protection current cannot continuously form a loop in the steel structure splash area. To make the cathodic protection effective in the steel structure splash area, it is necessary to artificially introduce a conductive medium on the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com