Degradable environment-friendly flocculus material and preparation method thereof

An environmentally friendly, wadding technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as unseen and unsuitable fillers, and achieve the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

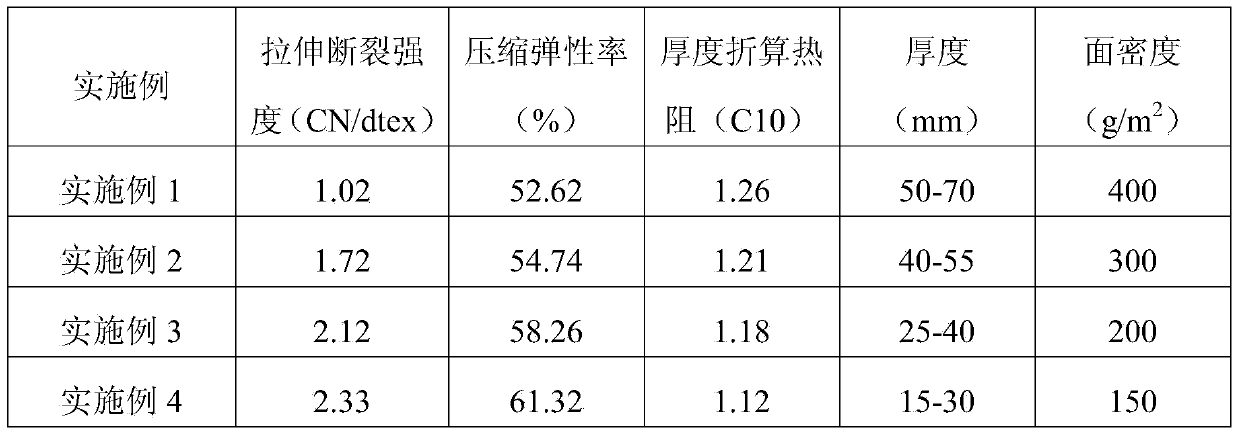

Examples

Embodiment 1

[0025] A) fiber raw material selection, by weight percentage (i.e. by mass %, hereinafter the same): kapok fiber 80%, polylactic acid hollow fiber 12% and polylactic acid sheath-core fiber 8%, obtain fiber raw material, wherein: kapok fiber The average length is 8mm, the diameter is 45μm, the wall thickness is 1μm, the hollowness is 85%, and the single fiber density is 0.29g / ㎝ 3, The linear density of the polylactic acid hollow fiber is 10D, the length is 38mm, and the melting point is 160°C; the linear density of the polylactic acid sheath-core fiber is 1.5D, the length is 38mm, the melting point of the skin layer is 100°C, and the melting point of the core layer is 160°C ;

[0026] B) into a web, first the fiber raw materials obtained by step A) are mixed with a cotton mixer and opened with an opener, and then carded into a web with a carding machine to obtain a grammage of 400g / m 2 Fiber cotton net;

[0027] C) Melting and bonding, introducing the fiber cotton web obtaine...

Embodiment 2

[0029] A) fiber raw material selection, take by weight percentage: kapok fiber 60%, polylactic acid hollow fiber 20% and polylactic acid sheath-core fiber 20%, obtain fiber raw material, wherein: the average length of kapok fiber is 12 mm, and diameter is 20 μ m, The wall thickness is 0.5μm, the hollowness is 87%, and the single fiber density is 0.29g / ㎝ 3 , The linear density of the polylactic acid hollow fiber is 6D, the length is 50mm, and the melting point is 165°C; the linear density of the polylactic acid sheath-core fiber is 1.7D, the length is 50mm, the melting point of the skin layer is 120°C, and the melting point of the core layer is 165°C ;

[0030] B) into a net, the fiber raw material obtained by step A) is mixed with a cotton mixer and opened with an opener, and then combed into a net with an air-laid machine to obtain a grammage of 300g / m 2 Fiber cotton net;

[0031] C) Melting and bonding, introducing the fiber cotton web obtained in step B) into an oven, the...

Embodiment 3

[0033] A) fiber raw material selection, get by weight percentage: kapok fiber 56%, polylactic acid hollow fiber 30% and polylactic acid sheath-core fiber 14%, obtain fiber raw material, wherein: the average length of kapok fiber is 16 mm, and diameter is 40 μ m, The wall thickness is 2μm, the hollowness is 83%, and the single fiber density is 0.29g / ㎝ 3 , the linear density of the polylactic acid hollow fiber is 4D, the length is 64mm, and the melting point is 168°C; the linear density of the polylactic acid sheath-core fiber is 1.8D, the length is 64mm, the melting point of the skin layer is 125°C, and the melting point of the core layer is 168°C ;

[0034] B) into a net, the fiber raw material obtained by step A) is mixed with a cotton mixer and opened with an opener, and then combed into a net with a carding machine to obtain a grammage of 200g / m 2 Fiber cotton net;

[0035] C) Melting and bonding, introducing the fiber cotton web obtained in step B) into an oven, the fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com