A high-rigidity rod screen drum and its manufacturing method

A manufacturing method and high-rigidity technology, applied in textiles, papermaking, fiber raw material processing, etc., can solve the problems of easy deformation and cracking of rod-shaped sieve drums, and achieve increased opening ratio, improved sieve drum life, improved rigidity and fatigue resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

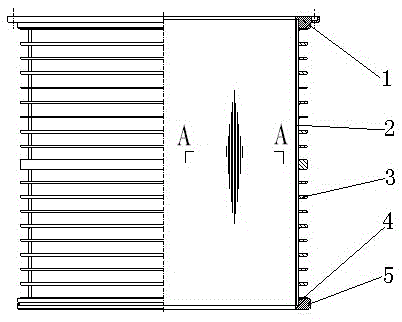

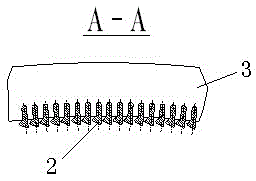

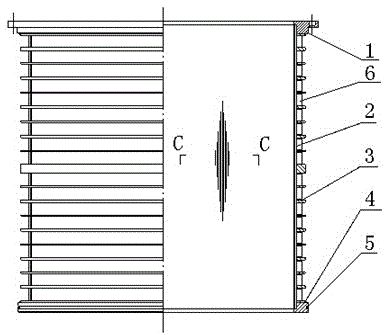

[0054] Example: The materials used in the high-rigidity rod screen drum of the present invention are all stainless steel 304 or 316L, and the slurry contacting working surface 62 and the clamping groove 61 of the special-shaped plate 6 are processed by CNC milling (see Image 6 , Figure 7 ), scratches and other defects are not allowed on the surface, the dimensional tolerance is controlled within ±0.02mm and the straightness is guaranteed. Process the installation notch, and ensure that the center line of the notch is perpendicular to the tangent line of the inner circle of the fixed ring. According to each group of eighteen rods 2, special-shaped plates 6 are installed in parallel between each group, and the depth of the notch is 5 ~5.5mm (see Figure 5 ). The processed special-shaped plate 6 and the bar 2 are evenly combined and embedded in the fixed ring 3, and put into a special hydraulic bulging mold, and the special-shaped plate 6 and the bar 2 are respectively expand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com