RA resin asphalt spreader and cleaning device thereof

A technology of resin asphalt and sprinkler, which is applied to roads, road repairs, roads, etc., can solve the problems of large cost investment, waste, and low efficiency, and achieve construction efficiency and construction quality assurance, efficiency improvement, and uniform spraying volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

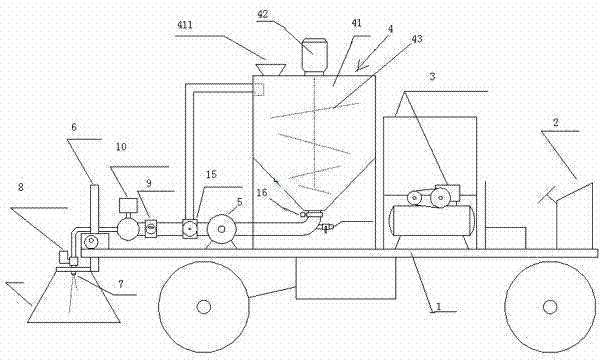

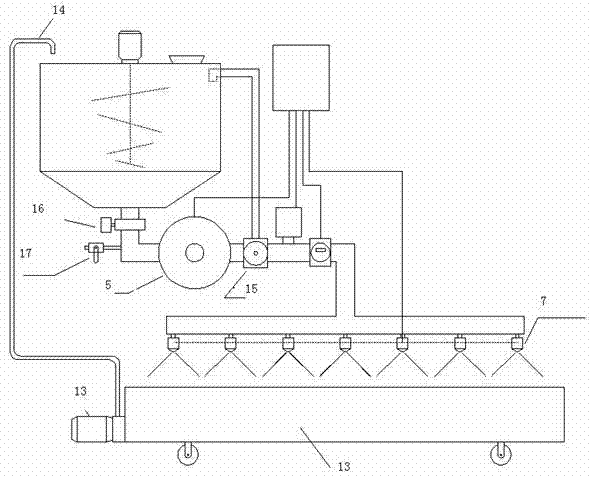

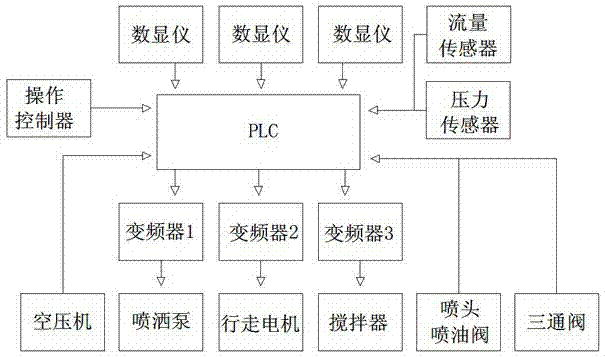

[0015] Such as figure 1 As shown in and 2, a RA resin asphalt spreader includes a trolley 1, on which a control cabinet 2, an engine and an air compressor 3, a mixing resin asphalt tank 4, and a conveying The pump 5 is provided with a lifter 6 at the leftmost end of the trolley 1, and a row of nozzles 7 is installed on the lifter 6. The generator and the air compressor are electrically connected, and a pneumatic valve 8 is arranged on the nozzle 7. The machine and the pneumatic valve 8 are connected by a pipeline; the output port of the mixing resin asphalt tank 4 is connected to the delivery pump 5 by a pipeline, and a flow meter 9 and a pressure sensor 10 are arranged between the delivery pump 5 and the nozzle 7 . Described mixing resin pitch tank 4 is made up of pitch tank 41, stirring motor 42 and stirring device 43, and stirring motor 42 is located at the top of pitch tank 41, and stirring device 43 is located in the pitch tank 41, and the output shaft of stirring motor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com