Anti-freeze flat plate solar collector and design method thereof

A technology of solar panels and heat collectors, applied in the field of solar heat collectors, to achieve the effects of preventing solid-liquid separation, uniform temperature distribution, and slowing down the start-up speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

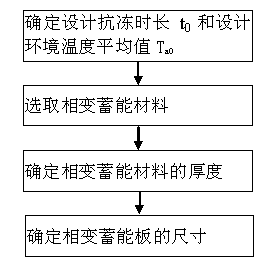

[0044] 1. According to the local meteorological conditions, determine the design antifreeze duration T 0 and design ambient temperature mean T a0 .

[0045] Taking Lanzhou as an example, there are 143 icy days with daily minimum temperature below 0°C. Figure 5 The anti-freezing time t of the icing day and the average temperature T of the environment during the no-sunlight period are given a . When K 1 and K 2 When the value is 0.9, the corresponding design antifreeze duration t 0 and the average temperature T of the environment during the time without sunlight a0 They are 18h and 264.6K respectively.

[0046] 2. Calculate the thickness of the phase change energy storage material according to formula (1)

[0047] The density of the phase change energy storage material is 1.47g / cm 3 , the phase change point is 5°C, the latent heat of phase change is 123.3KJ / (kg K), the liquid specific heat capacity is 14.38KJ / (kg K), the solid specific heat capacity is 5.56KJ / (kg K), t...

Embodiment 2

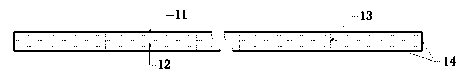

[0055] On the basis of Example 1, if the phase change point of the phase change energy storage material 12 is 8°C and other data remain unchanged, then the thickness of the phase change energy storage material 12 is 11.9mm, and the corresponding phase change energy storage plate bottom plate The height is changed to 13.9mm.

Embodiment 3

[0057] On the basis of Example 1, the Lanzhou area is changed to the Xi'an area, and there are 94 icy days in which the daily minimum temperature is lower than 0°C. Figure 6 The anti-freezing time t of the icing day and the average temperature T of the environment during the no-sunlight period are given a . When K 1 and K 2 When the value is 0.9, the corresponding design antifreeze duration t 0 and the average temperature T of the environment during the time without sunlight a0 They are 16h and 268.6K respectively. Then the thickness of the phase change energy storage material 12 is 5.9 mm, and the height of the lower bottom plate of the phase change energy storage plate is changed to 7.9 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com