Particulate matter sensor and particulate matter monitoring method

A particle sensor and particle technology, applied in the field of photoelectric detection, can solve the problems of large error in monitoring results, low optical energy density, and large detection area of the monitoring light source, and achieve the effect of small divergence angle and high optical energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

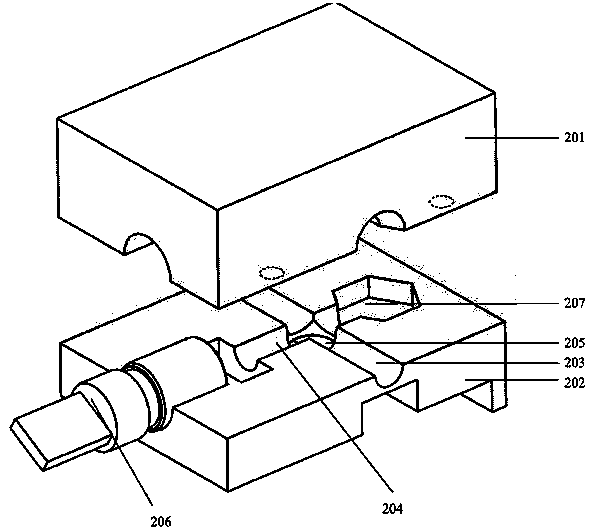

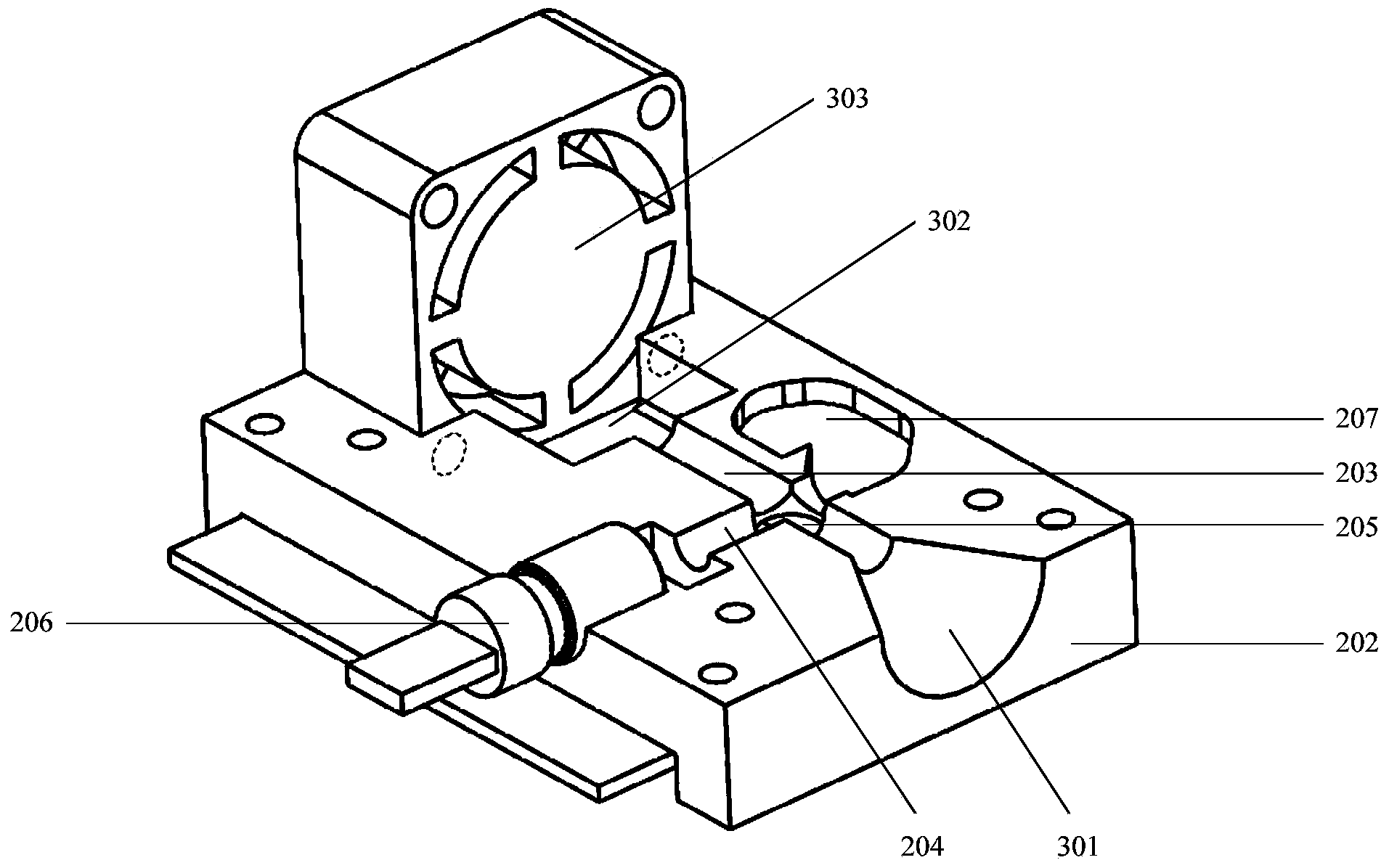

[0065] figure 2 It is a structural schematic diagram of Embodiment 1 of a particulate matter sensor in the present invention, and the particulate matter sensor includes:

[0066] The upper cover 201 and the base 202 , the upper cover 201 and the base 202 form a light-shielding space including an air flow channel 203 and a light transmission channel 204 .

[0067] The light-shielding space of the particle sensor is formed by the combination of the upper cover 201 and the base 202 , and the light-shielding space formed by the upper cover 201 and the base 202 includes an air flow channel 203 and a light transmission channel 204 .

[0068] like figure 2 As shown, the airflow passage 203 is a cylindrical passage through the particle sensor formed by a semicircular groove of the upper cover 201 and a semicircular groove of the base 202 . It should be noted here that the air flow channel 203 is not limited to figure 2 Cylindrical channels are shown in , but other shapes such as...

Embodiment 2

[0125] Figure 8 It is a flow chart of Embodiment 2 of a particulate matter monitoring method of the present invention. The method is a particulate matter monitoring method implemented by using the particulate matter sensor described in Embodiment 1. The method includes:

[0126] Step 801: Start the laser to output a laser beam in the optical transmission channel, the laser beam irradiates particles in the monitoring airflow in the intersecting area of the airflow channel and the optical transmission channel to scatter, and the monitoring airflow enters from one end of the airflow channel.

[0127] The monitoring airflow enters from one end of the airflow channel and exits from the other end of the airflow channel. Optionally, during specific implementation, the exhaust fan can be started, and the exhaust fan will discharge the air in the chamber from the particle sensor, and a negative pressure will be generated in the chamber, so that the monitored airflow enters the airfl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com