Ignition cable shield

A cable shielding and cable shielding layer technology, which is applied in the field of electromagnetic shielding ignition cables, can solve the problems that the weight of the multilayer metal shielding body of the ignition cable exceeds the specified requirements, the electromagnetic shielding performance cannot be satisfied, and the ignition cable has poor workmanship, etc., so as to adapt to harsh environments The effect of strong ability, good quality and high dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

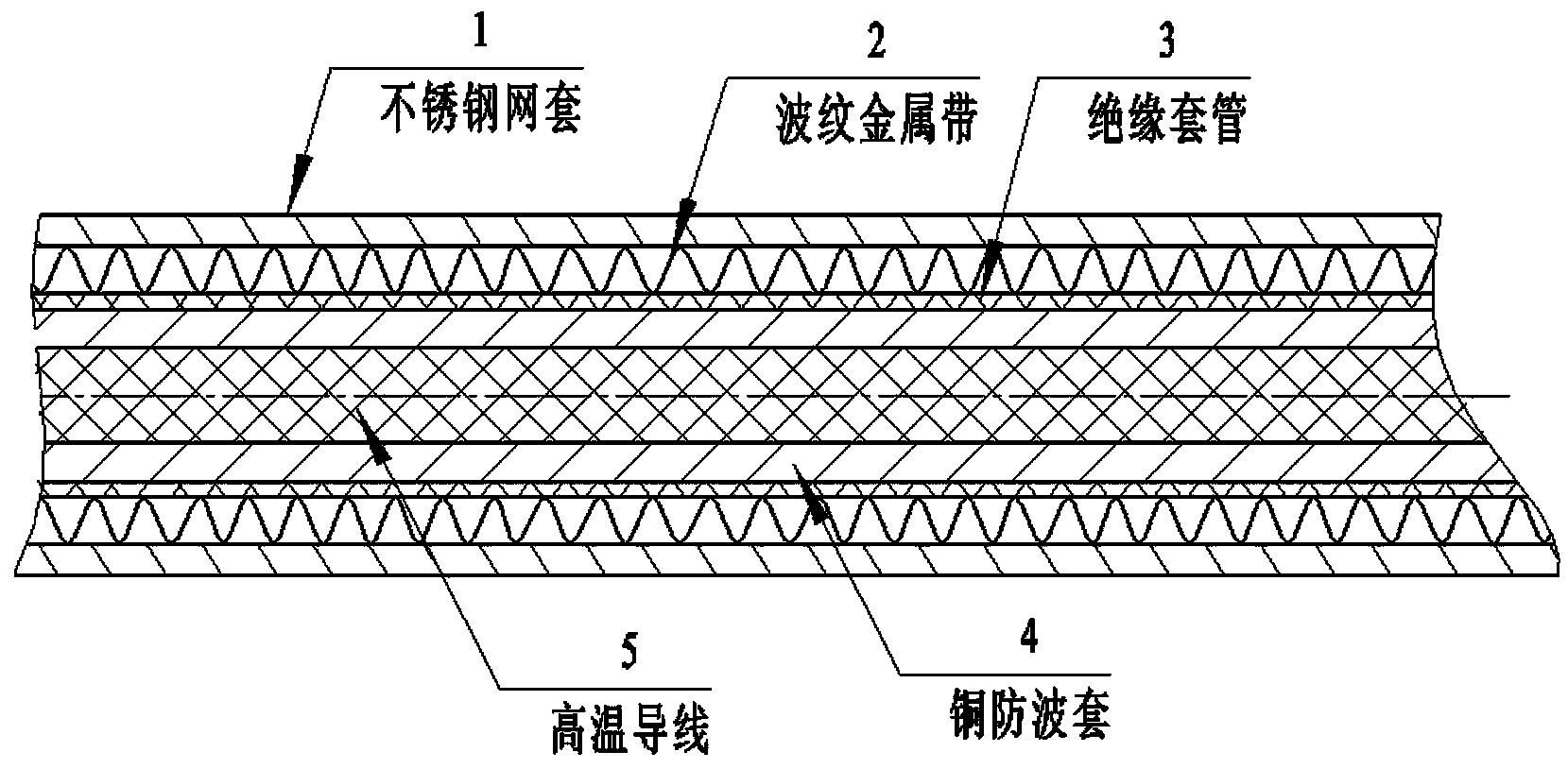

[0015] refer to figure 1 . In the ignition cable shielding body described below, the cable shielding layer is mainly composed of stainless steel mesh sleeve 1, corrugated metal belt 2, insulating sleeve 3 and copper anti-wave sleeve 4. The outer layer is made of metal braided stainless steel mesh sleeve and corrugated metal belt to form a double shielding structure. The middle layer adopts double shielding structure of corrugated metal strip and insulating sleeve. The inner layer adopts insulating sleeve + Copper anti-wave sleeve double shield insulation structure. The high-temperature wire 5 penetrates into the copper anti-wave sleeve 4 and is placed on the insulating sleeve 3. The corrugated metal strip 2 is half-folded on the outer surface of the insulating sleeve 3. The stainless steel mesh sleeve 1 is set on the corrugated metal strip 2 to form an ignition The electromagnetic compatibility ignition cable with the metal shield as the unit body of the cable can realize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com