Celery yogurt and production method thereof

A technology of yogurt and celery, applied in milk preparations, dairy products, applications, etc., can solve the problem of limited amount of celery added, achieve good flavor and taste, improve flavor, and good flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

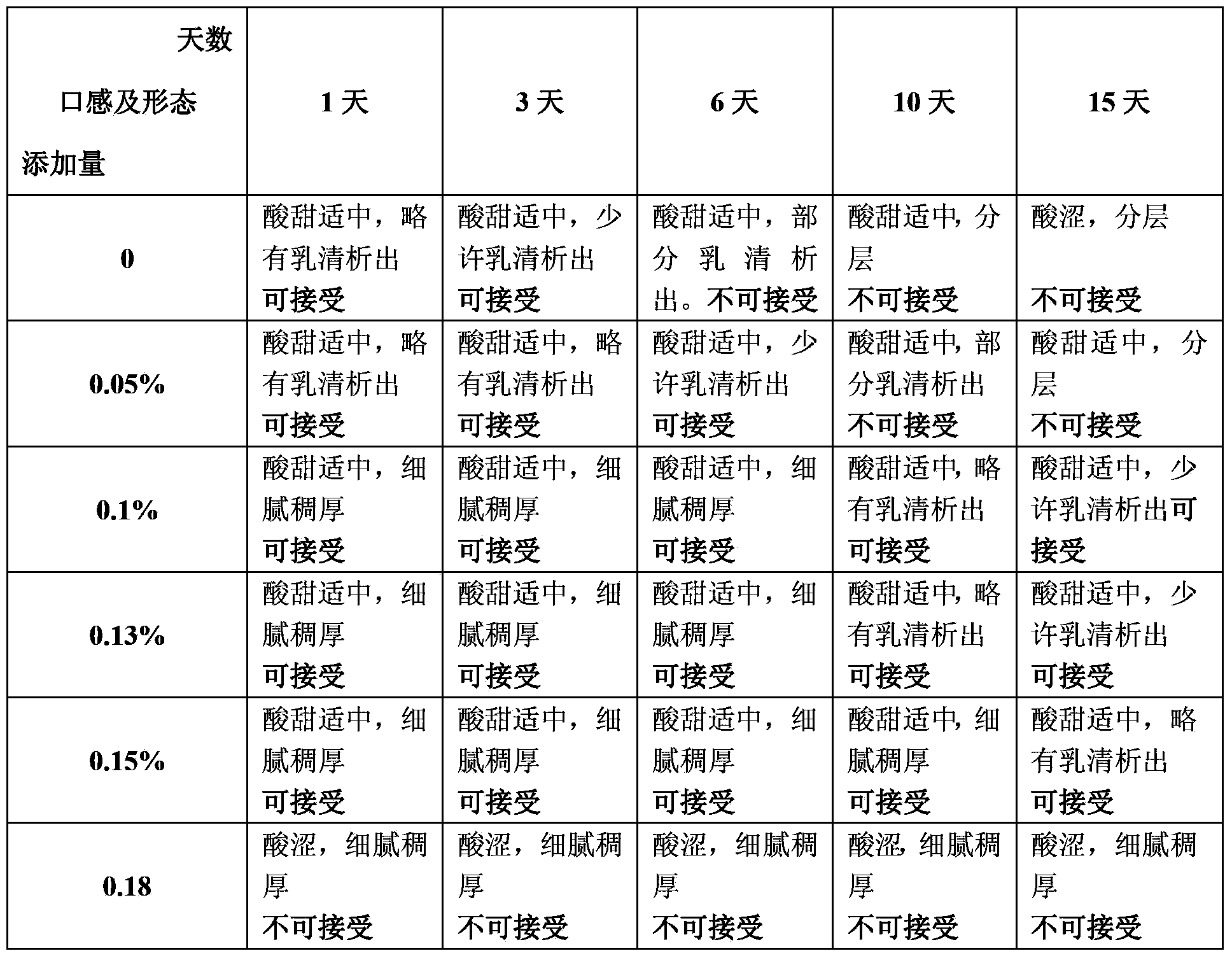

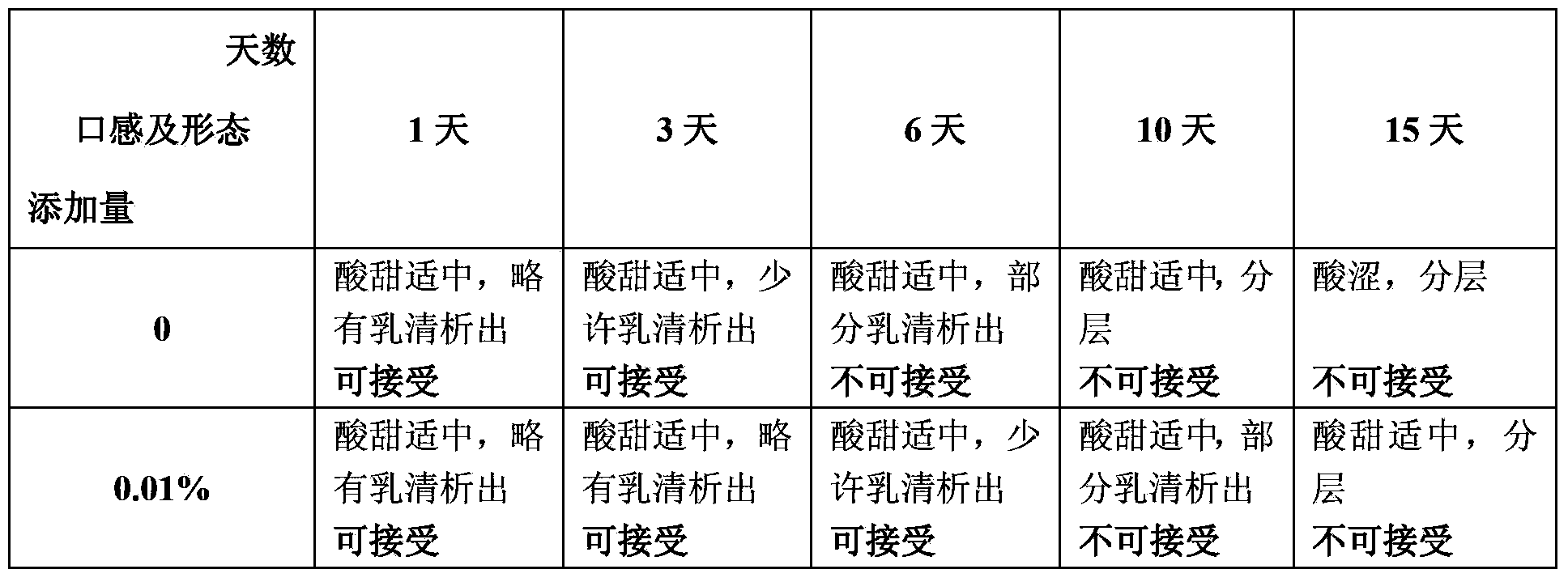

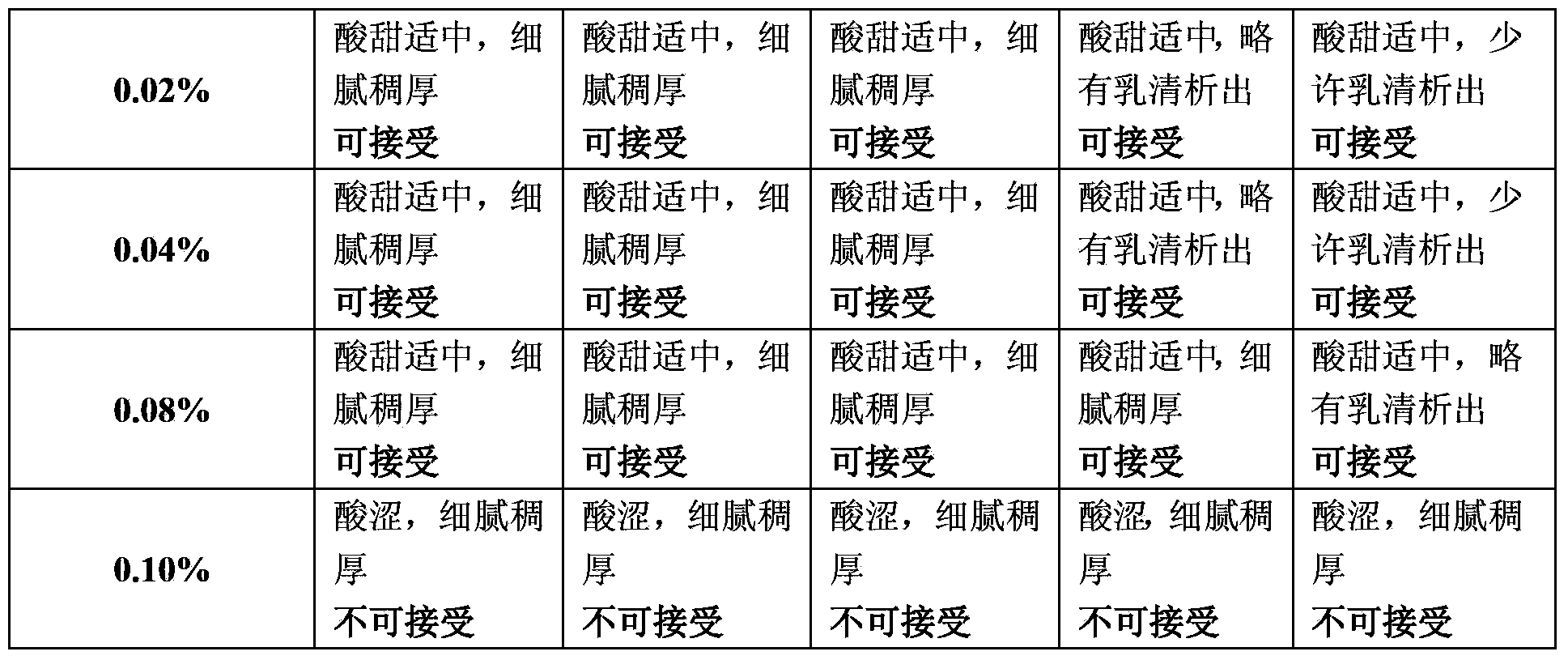

[0062] 1. Raw material formula (measured in 1000g)

[0063]

[0064]

[0065] Two, the making of the yogurt of the present embodiment mainly carries out according to the following operations:

[0066] 1. Selection of raw milk: select fresh milk that has passed the inspection, with protein content ≥ 2.9%, fat content ≥ 3.1%, and dry matter content about 13%;

[0067] 2. Ingredients: raise the temperature of the milk to 55°C, add celery juice and white sugar, and stir for 20 minutes to obtain the prepared milk material;

[0068] 3. Preheat the above prepared milk material to 65°C for homogenization, the homogenization pressure is 20Mpa; the homogenized material is sterilized at 95°C for 300s; the sterilized material is cooled to 41°C-43°C, inoculated Ferment the basic strain starter and kefir grains for 5-6 hours, stop the fermentation when the acidity reaches 75°T, break the yogurt and immediately cool down to 25°C, fill it, and refrigerate it at 2-6°C after filling Coo...

Embodiment 2

[0071] 1. Raw material formula (measured in 1000g)

[0072]

[0073] 2. The production of this embodiment is mainly carried out according to the following operations:

[0074] 1. Selection of raw milk: select fresh milk that has passed the inspection, with protein content ≥ 2.9%, fat content ≥ 3.1%, and dry matter content about 13%;

[0075] 2. Ingredients: raise the temperature of the milk to 50°C, add celery juice and white sugar, and stir for 25 minutes to obtain the prepared milk material;

[0076] 3. Preheat the above-mentioned prepared milk material to 60°C for homogenization, the homogenization pressure is 25Mpa; the homogenized material is sterilized at 95°C for 300s; the sterilized material is cooled to 41°C-43°C, and inoculated Ferment the basic strain starter and kefir grains for 5-6 hours, stop the fermentation when the acidity reaches 80°T, break the yogurt and immediately cool down to 25°C, fill it, and refrigerate it at 2-6°C after filling Cook for 24 hours...

Embodiment 3

[0079] 1. Raw material formula (measured in 1000g)

[0080]

[0081] The celery yoghurt of the present example was prepared as described in Example 1.

[0082] The yogurt produced according to this example has soft flavor, unique and beautiful taste, delicate and smooth taste, and good texture. It can be refrigerated at 2°C to 10°C for more than 15 days without unacceptable breakdown during the shelf life. During the storage period, the product maintains a delicate and smooth taste, and the flavor is basically unchanged compared with the fresh product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com