Abelmoschus manilhot stem and leaf high-efficiency comprehensive utilization method

A technology of hollyhock, stems and leaves, applied in the field of high-efficiency comprehensive utilization of hollyhock stems and leaves, can solve problems such as no edible value, achieve the effect of filling the gap in processing technology and product development, high conversion rate and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Remove the flowers and buds of the hollyhock plant, cut off the whole plant from a height of 20cm above the ground, rinse it with drinking water, put it in a stainless steel mesh sieve, and drain the water.

[0046] 2. Cut step 1 into small pieces with a length of 1 cm, and dry them with low-temperature airflow at 50°C until the water content reaches 2%.

[0047] 3. Grind step 2 through a 20-mesh electric sieve with a high-speed pulverizer.

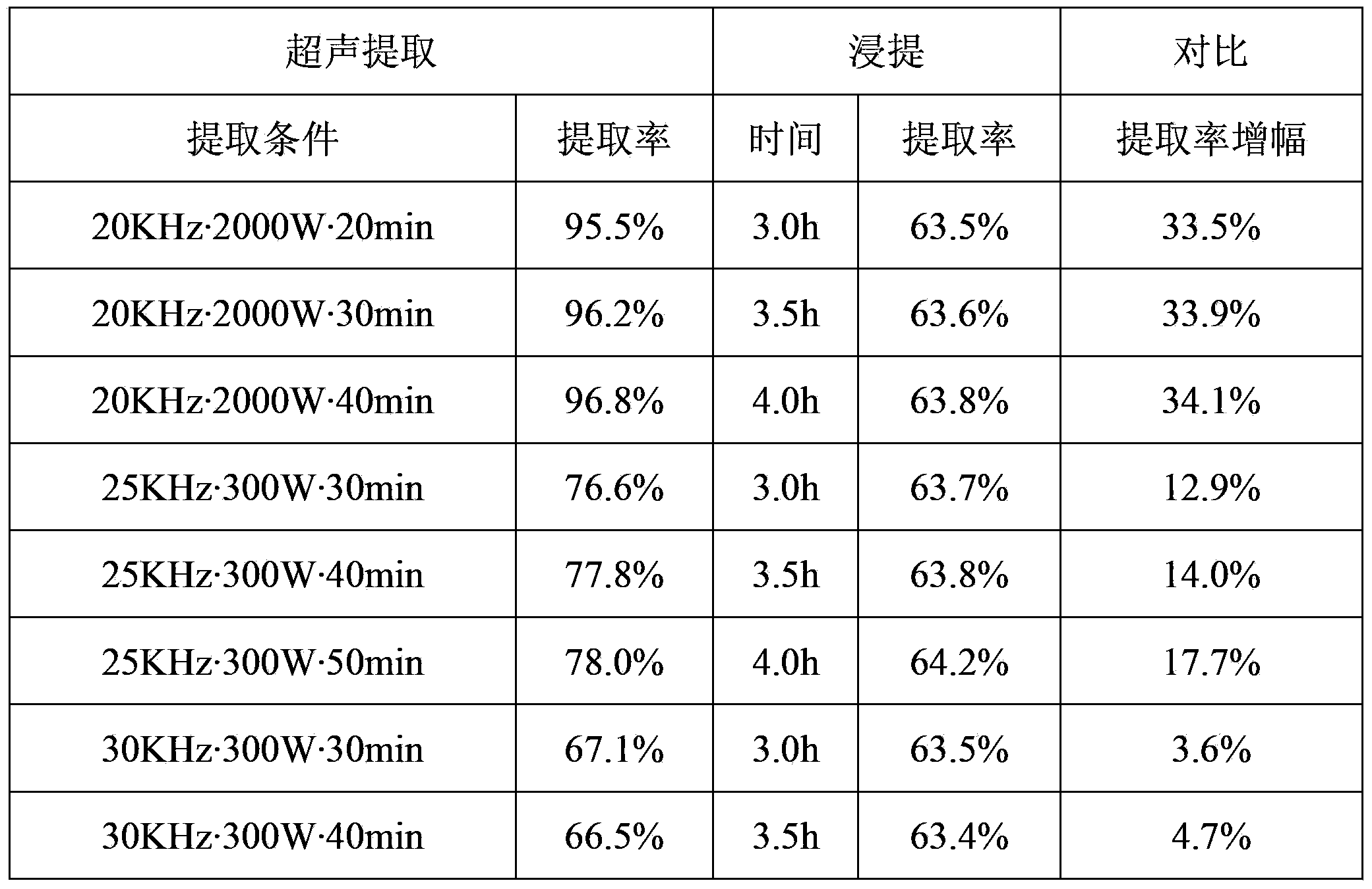

[0048] 4. Put step 3 into the ultrasonic multifunctional extraction tank to extract flavonoids, the sound wave range is 2×10 4 -10 9 , the power is 20KH z ·2000W, the time is 40min, the concentration of solvent (ethanol) is 40%, the temperature is 30℃, the ratio of solid to liquid is 1:20, and the particle size of the raw material is 20 mesh.

[0049] 5. Pass step 4 through a high-speed liquid slag separation centrifuge to automatically discharge slag at a speed of 3000rpm for 30 minutes to remove the coarse slag, and then go...

Embodiment 2

[0055] 1. Take the hollyhock plant with the flowers and buds removed, cut off the whole plant from a height of 25cm above the ground, rinse it with drinking water, put it in a stainless steel mesh sieve, and drain the water.

[0056] 2. Cut step 1 into 2cm long pieces, and dry them with low-temperature airflow at 60°C until the water content reaches 3%.

[0057] 3. Use a high-speed pulverizer to pulverize step 2 through a 25-mesh electric sieve.

[0058] 4. Put step 3 into the ultrasonic multifunctional extraction tank to extract flavonoids, the sound wave range is 2×10 4 -10 9, Power 20KH z ·2000w, time 30min, ethanol concentration 50%, temperature 40℃, ratio of solid to liquid 1:25, raw material particle size 30 mesh.

[0059] 5. Pass step 4) through a high-speed liquid slag separation centrifuge to automatically discharge slag at a speed of 4000rpm for 20 minutes to remove coarse slag, and then pass through membrane filtration systems such as microfiltration, ultrafiltra...

Embodiment 3

[0065] 1. Take the hollyhock plant with the flowers and buds removed, cut off the whole plant from a height of 30cm above the ground, rinse it with drinking water, put it in a stainless steel mesh sieve, and drain the water.

[0066] 2. Cut step 1 into 3cm-long pieces, and dry them with low-temperature airflow at 55°C until the water content reaches 4%.

[0067] 3. Grind step 2 with a high-speed pulverizer and pass through a 30-mesh electric sieve.

[0068] 4. Put step 3 into the ultrasonic multifunctional extraction tank to extract flavonoids, the sound wave range is 2×10 4 -10 9 The power is 25KHz·300W, the time is 30 minutes, the concentration of solvent (ethanol) is 60%, the temperature is 50°C, the ratio of solid to liquid is 1:30, and the particle size of the raw material is 25 mesh.

[0069] 5. Pass step 4 through a high-speed liquid slag separation centrifuge to automatically discharge slag at a speed of 5000 rpm for 25 minutes to remove the coarse slag. Then, micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com