A method of corn pretreatment and a method of using corn to prepare feed

A pretreatment and corn technology, applied in animal feed, grain treatment, animal feed, etc., can solve the problems of high toxin content and difficulty in ensuring the quality and safety of feed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

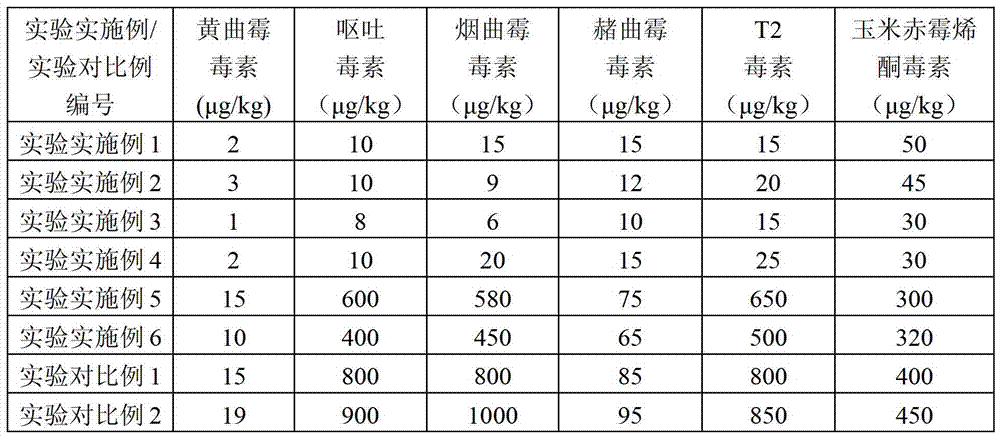

Embodiment 1

[0056] (1) Take 500 tons of corn kernels from the Northeast, and introduce them into the double-layer cylindrical sieve for screening and removal of impurities. Among them, based on the material volume of the double-layer cylindrical sieve per cubic meter, the corn kernels are placed in the double-layer cylindrical sieve The feed rate in the sieve is 100 tons / hour, the rotating speed of the double-layer cylindrical sieve is 18 rpm, and the screening time is 0.2 hours. Obtained corn kernels.

[0057] (2) Introduce the impurity-removed corn kernels obtained in step (1) into a vibrating sieve to screen and remove damaged kernels, wherein, based on the material volume of the vibrating sieve per cubic meter, the feed amount of corn kernels in the vibrating sieve The vibration frequency of the vibrating screen is 2800 Hz, the amplitude is 7 mm, and the diameter of the lower screen mesh is 7 mm. The screening time was 0.3 hours. Obtain corn kernels and undersieves from which broken...

Embodiment 2

[0060] (1) Take 500 tons of corn kernels from the Northeast, and introduce them into the double-layer cylindrical sieve for screening and removal of impurities. Among them, based on the material volume of the double-layer cylindrical sieve per cubic meter, the corn kernels are placed in the double-layer cylindrical sieve The feed rate in the sieve is 90 t / h, and the double-deck drum sieve rotates at 15 rpm. The screening time was 0.3 hours. Obtained corn kernels.

[0061] (2) Introduce the impurity-removed corn kernels obtained in step (1) into a vibrating sieve to screen and remove damaged kernels, wherein, based on the material volume of the vibrating sieve per cubic meter, the feed of corn kernels in the vibrating sieve The capacity is 4 tons per hour, the vibration frequency of the vibrating screen is 2700Hz, the amplitude is 5.5 mm, and the mesh diameter of the lower screen is 6 mm. The screening time was 0.5 hours. Obtain corn kernels and undersieves from which broken...

Embodiment 3

[0064] (1) Take 500 tons of corn kernels from the Northeast, and introduce them into the double-layer cylindrical sieve for screening and removal of impurities. Among them, based on the material volume of the double-layer cylindrical sieve per cubic meter, the corn kernels are placed in the double-layer cylindrical sieve The feed rate in the sieve was 110 t / h, and the rotational speed of the double-deck drum sieve was 20 rpm. The screening time was 0.25 hours. Obtained corn kernels.

[0065] (2) Introduce the impurity-removed corn kernels obtained in step (1) into a vibrating sieve to screen and remove damaged kernels, wherein, based on the material volume of the vibrating sieve per cubic meter, the feed of corn kernels in the vibrating sieve The capacity is 5 tons per hour, the vibration frequency of the vibrating screen is 2900Hz, the amplitude is 8 mm, and the diameter of the screen mesh of the lower layer is 8 mm. The screening time was 0.4 hours. Obtain corn kernels an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com