Welding method to control welding deformation and improve weld seam quality

A welding method and welding deformation technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problem of difficulty in ensuring that the material will not be deformed, so as to improve the welding quality rate, improve welding quality, and reduce material deformation. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Referring to the accompanying drawings, a welding method for controlling welding deformation and improving weld seam quality specifically includes the following steps:

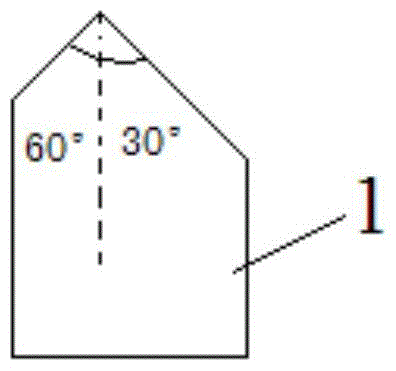

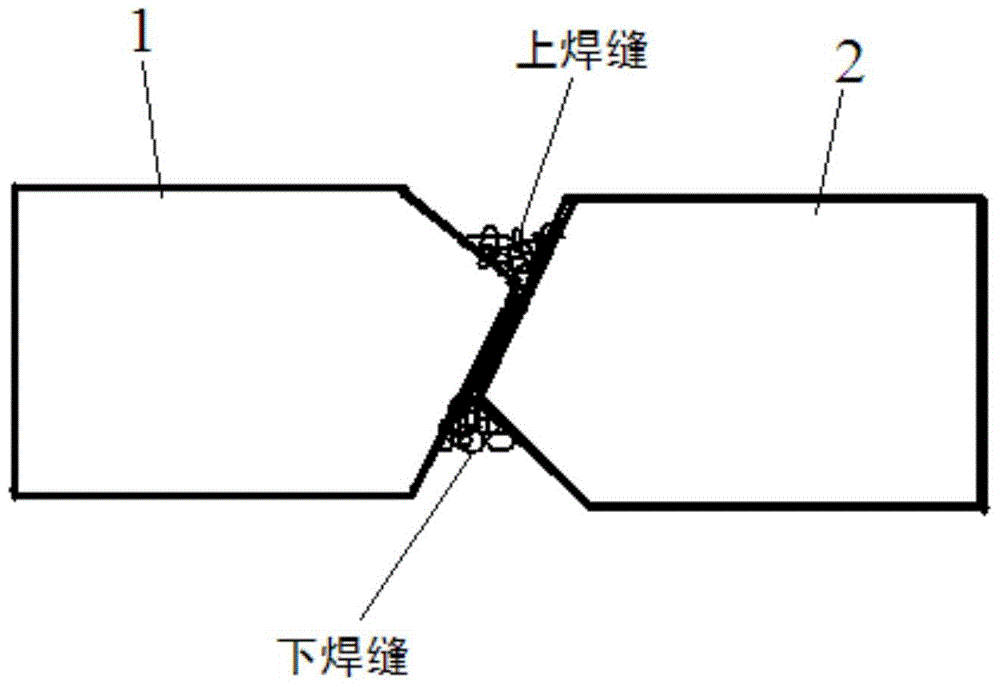

[0020] (1) Select two metal plates 1 and 2 as the butt weldment, and according to the shape of the two metal plates 1 and 2, respectively open slopes of appropriate degrees on the upper and lower sides of the welding surfaces of the two metal plates 1 and 2 mouth;

[0021] (2) According to the materials of the two metal plates 1 and 2, select a suitable electrode and bake the electrode;

[0022] (3) Clean the surfaces of the two metal plates 1 and 2, and polish the grooves on the upper and lower sides of the two metal plates 1 and 2 until bright;

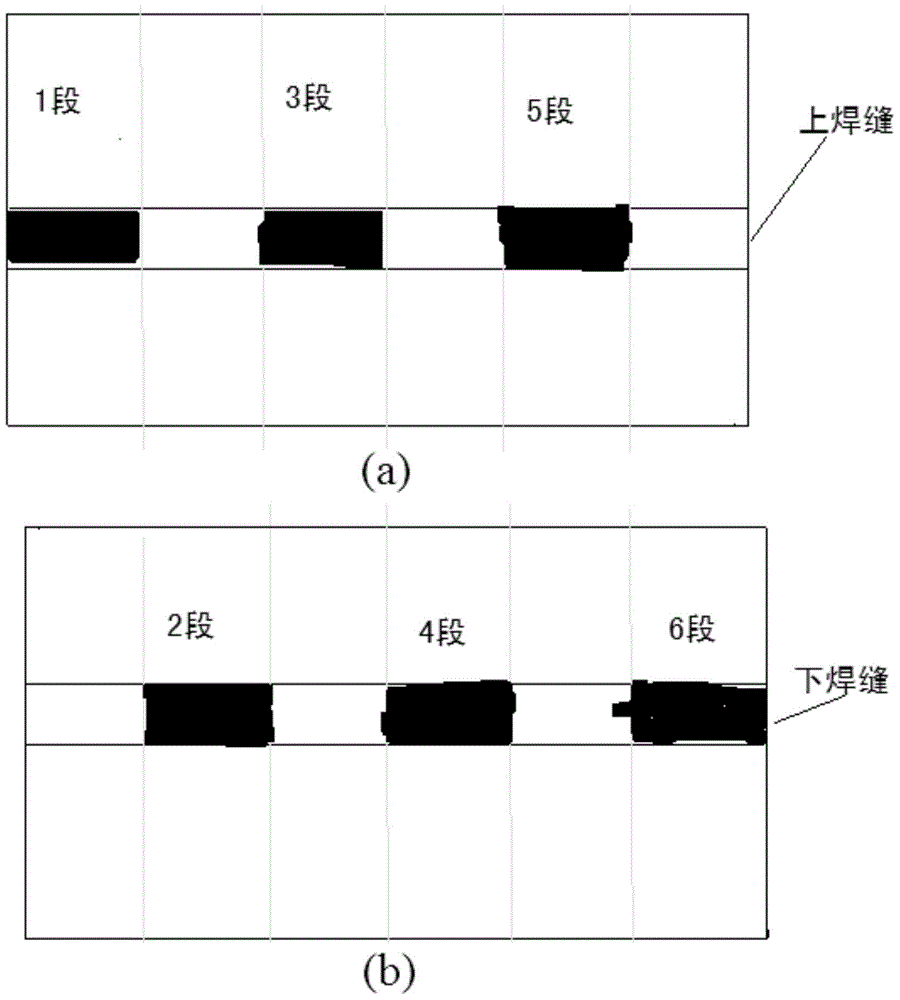

[0023] (4) Connect the groove on the upper side of the welding surface of one metal sheet in the two processed metal sheets 1 and 2 to the groove on the lower side of the welding surface of the other metal sheet, and use the baked welding rod for welding. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com