Pipeline flexible foamed plastic pasting method and pipeline

A flexible foam and pipe technology, applied in chemical instruments and methods, material gluing, synthetic resin layered products, etc., can solve problems such as inability to achieve rapid bonding, and achieve low curing temperature, short time, and good construction technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

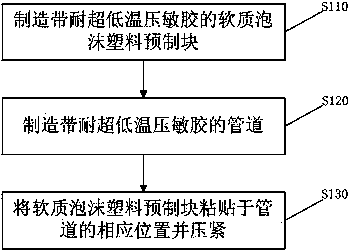

[0026] In view of the fact that China's new generation of launch vehicles uses liquid oxygen / kerosene low-temperature fuel, it is necessary to use foam plastics for thermal insulation of fuel storage tanks and low-temperature pipelines. However, existing two-component and one-component polyurethane adhesives have the technical problem of being unable to quickly paste foam plastics on low-temperature pipes because of their long curing cycle. Therefore, the present invention combines the development of ultra-low temperature-resistant pressure-sensitive adhesives, uses ultra-low-temperature-resistant pressure-sensitive adhesives in the quick pasting of soft foam plastics for low-temperature pipelines of launch vehicles, and proposes that pressure-sensitive adhesives can be bonded by hand pressure to achieve Paste quickly.

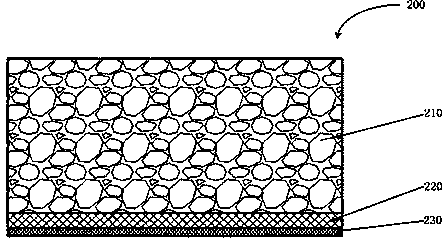

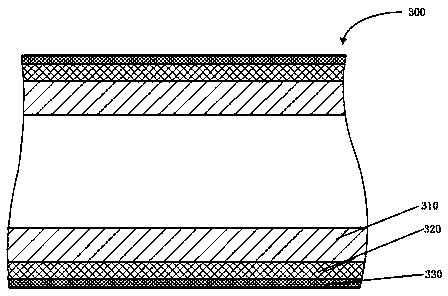

[0027] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com