A device for microwave heating and calcining powder materials with high whiteness

A powder material, microwave heating technology, applied in the direction of silica, aluminum silicate, silicate, etc., can solve the problems of microwave reaction device description, etc., achieve good hiding power and stability, save calcination reaction time, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The described embodiments are only some of the embodiments of the invention. All other embodiments without creative achievements based on the embodiments of the present invention belong to the protection scope of the present invention.

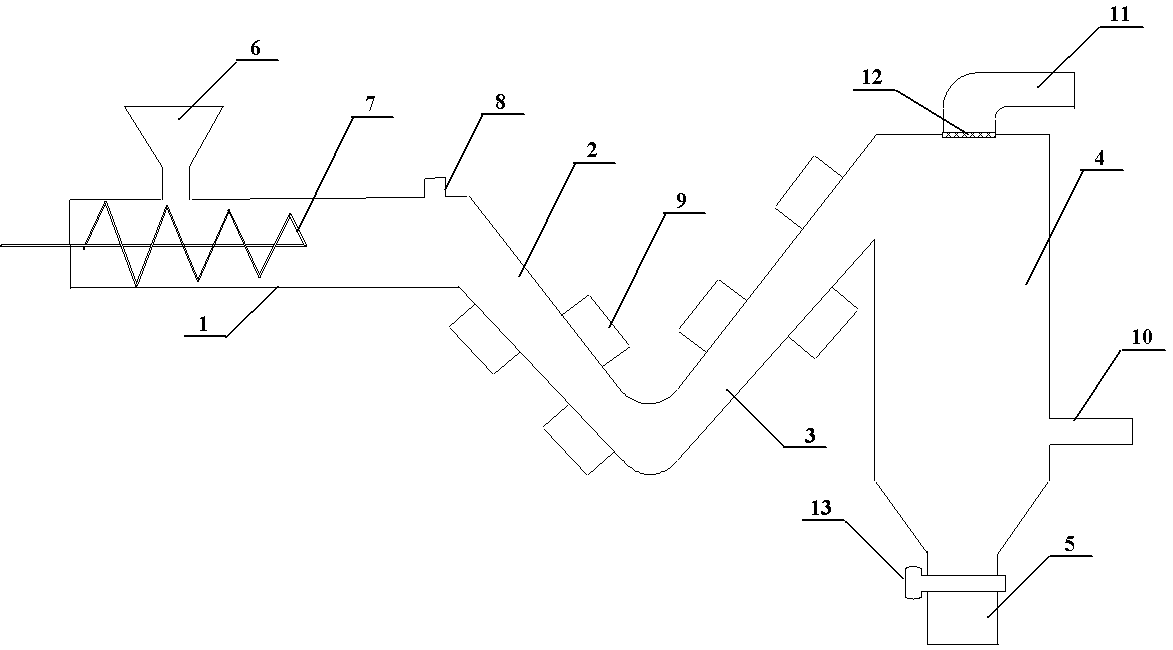

[0026] according to figure 1 A device for microwave heating and calcining powder materials with high whiteness is shown, including a feeding chamber 1, a first reaction chamber 2, a second reaction chamber 3, a collector 4, and a discharge port 5:

[0027] At the feeding chamber 1, the raw material of diatomite and 1% sodium hydroxide is fed through the feeding port 6, and is continuously extruded into the first reaction chamber 2 of the microwave reactor by the screw 7, and through this extruding Diatomaceous earth moves in the whole calcination device through the input mode.

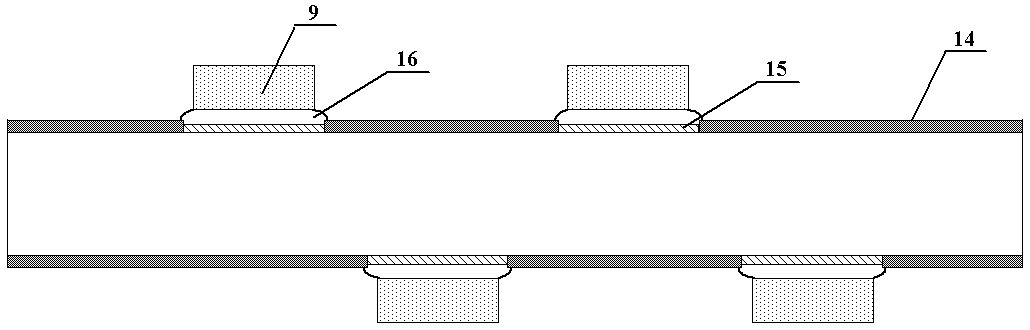

[0028] The microwave reaction chamber is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com