Panel display substrate glass composition

A flat-panel display and substrate technology, which is applied in the field of alkaline earth aluminoborosilicate glass components, can solve the problems of toxicity, low temperature of clarified gas, and low effectiveness of glass bubbles, and achieves environmental friendliness, low melting temperature, and reduced melting temperature. Effect

Inactive Publication Date: 2015-01-14

TUNGHSU GRP

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0035] The present invention will be further described below with specific examples.

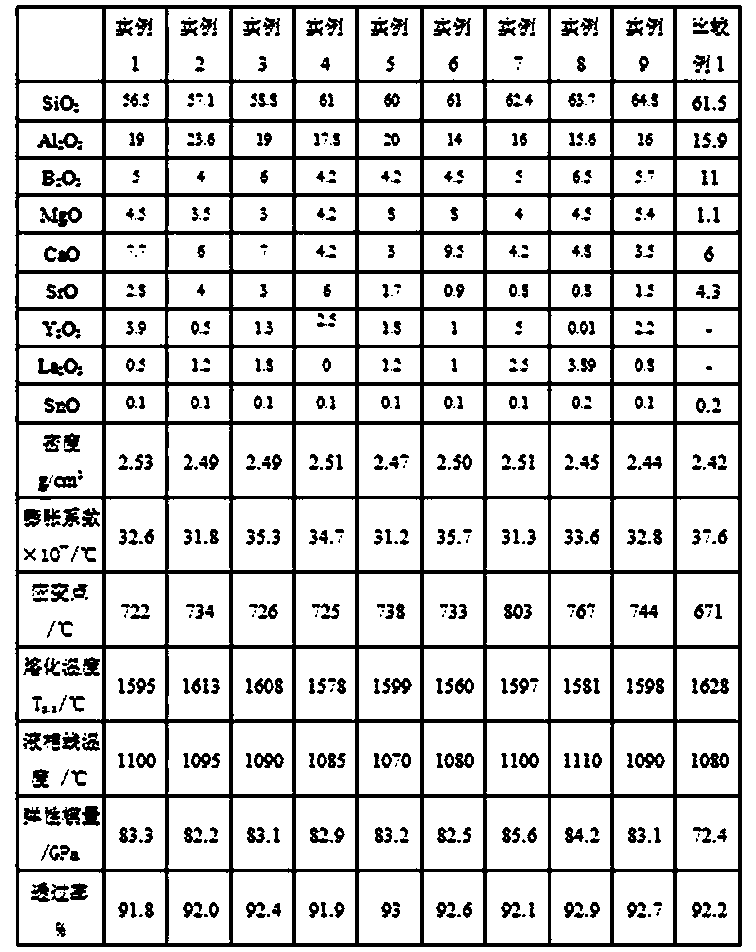

[0036] Table 1 shows the specific formulations of the substrate glasses in Examples 1 to 9, and also contains a comparative example, which is used to compare and illustrate the performance of the glass of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a panel display substrate glass composition which comprises the following components in percentage by weight: 56-65% of SiO2, 15-24% of Al2O3, 4-6.5% of B2O3, 3-8% of MgO, 3-10% of CaO, 0.1-6% of SrO, 0.01-5% of Y2O3 and 0.01-4% of La2O3. By adopting the technical scheme, the composition has the following advantages: the thermal expansion coefficient at 50-380 DEG C is 28-37*10<-7> / DEG C, the strain point is higher than 720 DEG C, the density is less than 2.55 g / cm<3>, and the liquidus temperature is lower than 1150 DEG C. The panel display glass substrate is environment-friendly and stable in performance, and has important functions on enhancing the production yield, reducing the energy consumption and controlling the cost.

Description

technical field [0001] The invention relates to an alkaline earth aluminoborosilicate glass component, which can be widely used in the production of glass substrates for flat-panel displays, and is especially suitable for low-temperature polysilicon thin-film transistor liquid crystal display (LTPS TFT-LCD) substrate glass and organic electroluminescence displays (OEL) substrate glass. Background technique [0002] With the rapid development of the flat panel display industry, the demand for various display devices is increasing, such as active matrix liquid crystal display (AMLCD), organic light emitting diode (OLED) and active matrix liquid crystal display (LTPS TFT) using low temperature polysilicon technology. -LCD) devices, these display devices are based on the use of thin-film semiconductor materials to produce thin-film transistor (TFT) technology. At present, TFT can be divided into amorphous silicon (a-Si) TFT, polycrystalline silicon (p-Si) TFT and single crystal...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C3/095

CPCC03C3/095

Inventor 张广涛闫冬成田颖刘文泰李兆廷

Owner TUNGHSU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com