Martensite stainless steel with high hardness, strong antibacterial property and excellent corrosion resistance, and heat treatment method thereof

A martensitic stainless steel, antibacterial technology, applied in the field of stainless steel materials, can solve the problems of limited application, decline, and corrosion resistance decline, and achieve the effects of excellent antibacterial properties, excellent corrosion resistance, and strong antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the chemical composition of the martensitic antibacterial stainless steel is (% by weight):

[0031] C: 0.34%, Cr: 13.76%, Mo: 0.79%, Cu: 3.42%, N: 0.06%, the rest is Fe; impurity element content: Si≤1.00%, Mn≤1.00%, P≤0.040%, S≤ 0.030%.

[0032] The heat treatment process of the above-mentioned martensitic antibacterial stainless steel is:

[0033] Insulate at 1080°C for 0.5 hours, cool the oil to room temperature, keep it in liquid nitrogen (-196°C) for 0.5 hours, then raise the temperature to 700°C and keep it for 2 hours to precipitate the copper-rich phase, air cool to room temperature; then keep at 1000°C for 10 Minutes of water quenching; finally at 500 ° C for 1 hour.

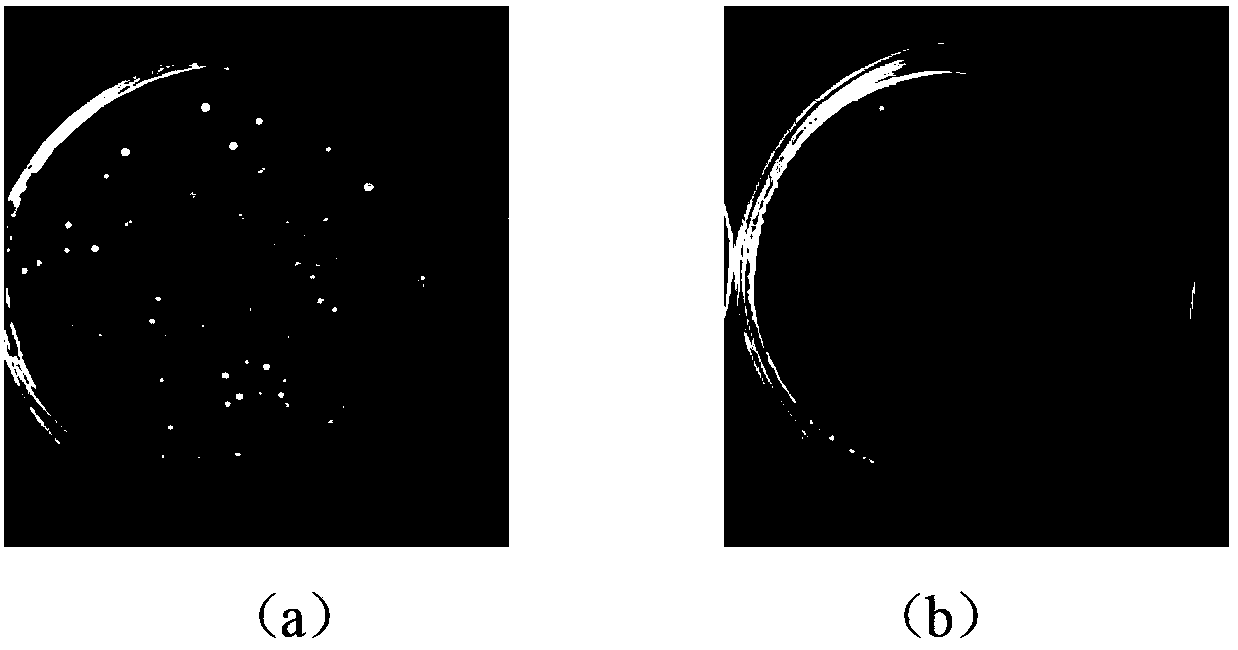

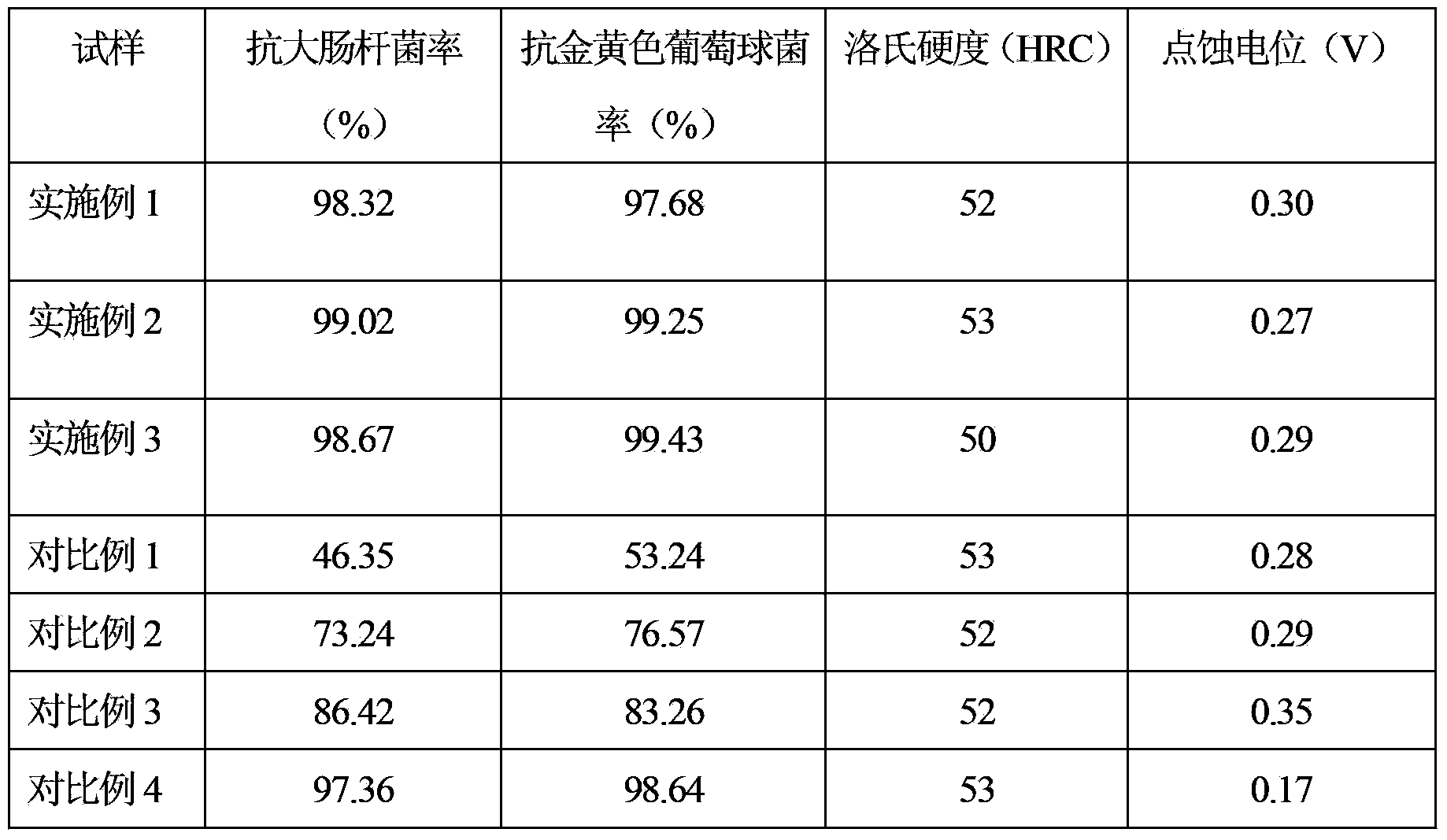

[0034] Antibacterial results such as figure 1 As shown in (b), it can be seen that compared with the control sample 3Cr13Mo stainless steel, the martensitic antibacterial stainless steel has excellent bactericidal ability, and the hardness test and pitting corrosion resista...

Embodiment 2

[0036] In this embodiment, the chemical composition of the martensitic antibacterial stainless steel is (% by weight):

[0037] C: 0.30%, Cr: 13.14%, Mo: 0.67%, Cu: 3.14%, N: 0.07%, the rest is Fe; impurity element content: Si≤1.00%, Mn≤1.00%, P≤0.040%, S≤ 0.030%.

[0038] The heat treatment process of the above-mentioned martensitic antibacterial stainless steel is:

[0039] Insulate at 1060°C for 0.5 hours, cool the oil to room temperature, then keep it in liquid nitrogen (-196°C) for 0.5 hours, then raise the temperature to 650°C and keep it for 4 hours to precipitate the copper-rich phase, then air-cool or water-cool to room temperature; then at 980 Incubate at ℃ for 5 minutes and water quench; finally incubate at 480℃ for 1 hour.

Embodiment 3

[0041] In this embodiment, the chemical composition of the martensitic antibacterial stainless steel is (% by weight):

[0042] C: 0.29%, Cr: 12.78%, Mo: 0.62%, Cu: 2.8%, N: 0.04%, the rest is Fe; impurity element content: Si≤1.00%, Mn≤1.00%, P≤0.040%, S≤ 0.030%.

[0043] The heat treatment process of the above-mentioned martensitic antibacterial stainless steel is:

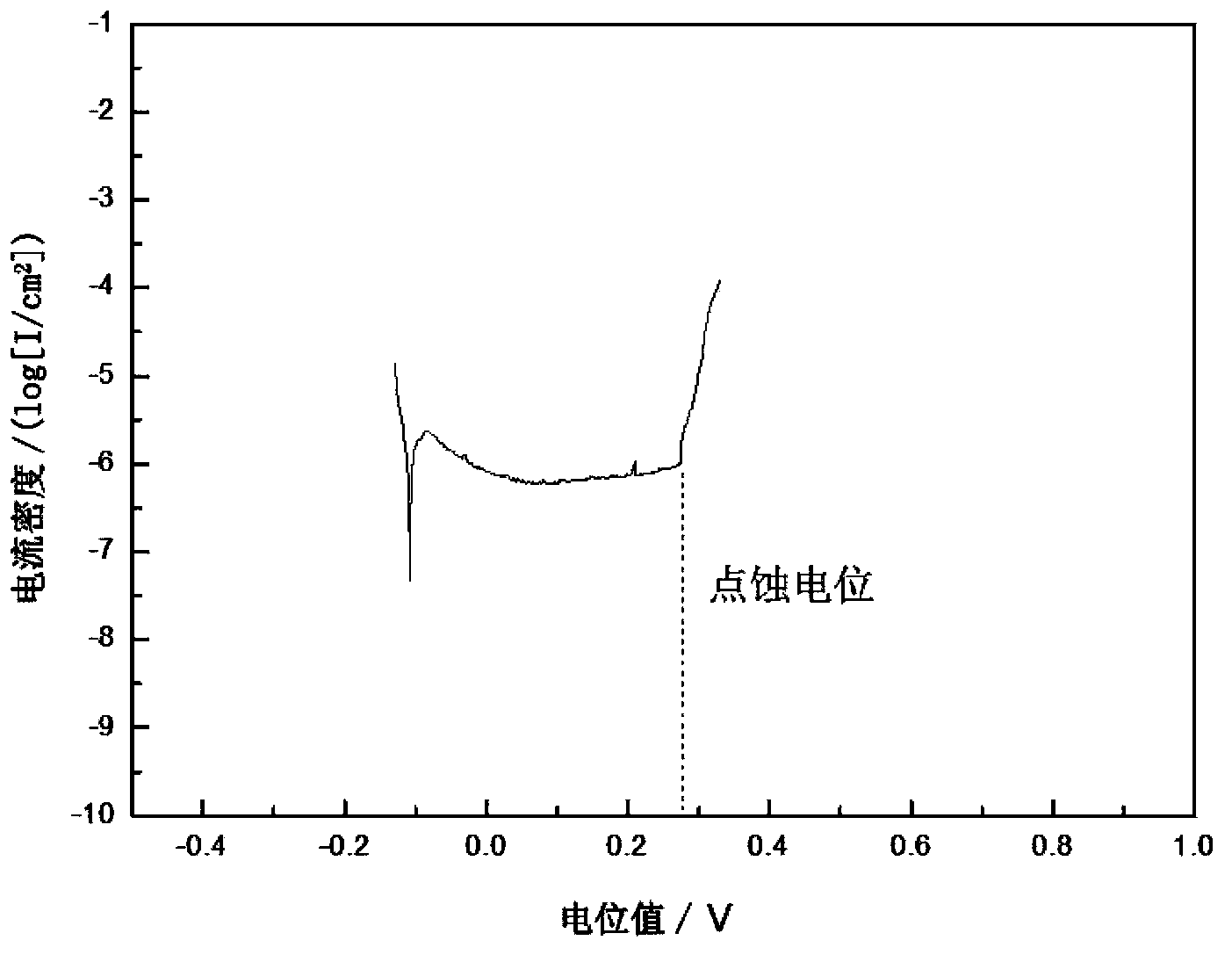

[0044]Insulate at 1040°C for 0.5 hours. After the oil is cooled to room temperature, keep it in liquid nitrogen (-196°C) for 0.5 hours, then raise the temperature to 720°C and keep it for 4 hours to precipitate the copper-rich phase, then air cool to room temperature; then keep at 930°C for 3 hours Minutes of water quenching, and finally at 530 ° C for 2 hours. The polarization curve of the present embodiment martensitic antibacterial stainless steel is as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com